Flow control valve for engine cooling water

a flow control valve and engine technology, applied in the direction of engine cooling apparatus, machines/engines, mechanical equipment, etc., can solve the problems of insufficient operation of the control valve, difficult cancellation of the driving load applied to the flow control, and extreme high fluid pressure applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

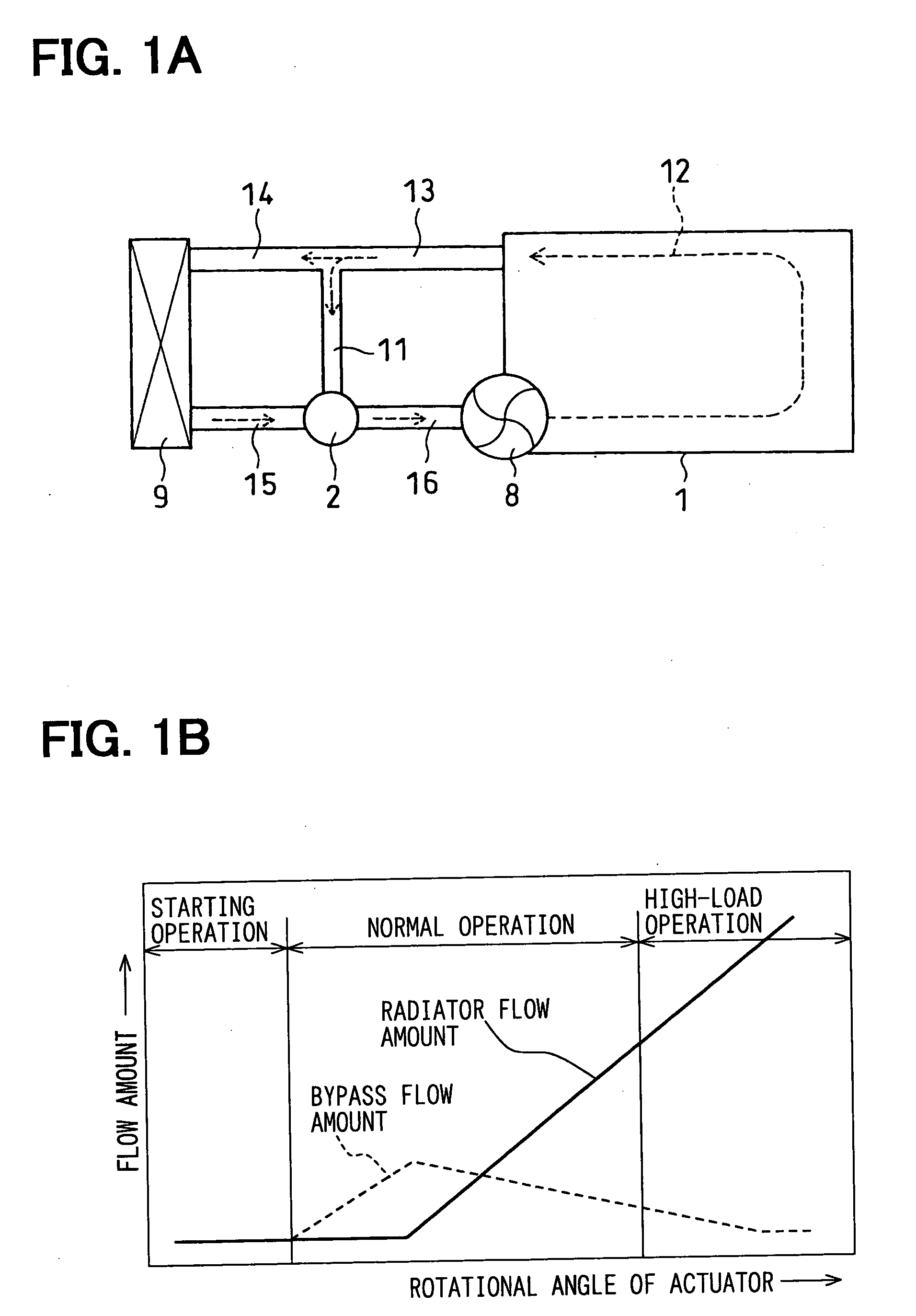

[0030]FIGS. 1A to 4C show a first embodiment of the present invention, wherein FIG. 1A shows a schematic view showing an engine cooling system for a water-cooled engine, and FIG. 1B is a graph showing characteristics of a radiator flow amount and a bypass flow amount with respect to a rotational angle of an actuator.

[0031] A flow control system according to the present invention comprises an engine cooling system for a water-cooled engine 1 having a cooling water circuit, a flow control valve 2 provided in the cooling water circuit, an electronic control unit (not shown and called hereinafter as ECU) for electronically controlling an opening degree of the flow control valve 2 depending on operational conditions of the engine 1. The flow control valve 2 comprises, as shown in FIG. 2, an actuator 3 to be electronically operated by the ECU, a valve housing 4 which also forms a part of an interfluent portion of the water cooling circuit, a valve body 5 (also referred to as a first spoo...

second embodiment

[0079] A second embodiment will be explained with reference to FIGS. 5A to 5D, wherein the second embodiment differs from the first embodiment in that the first pressure adjusting passage 61 is modified, instead of providing the cut-out portion 24 at the rotor shaft 21.

[0080]FIG. 5A shows a cross sectional view of the cylindrical portion 5c of the first spool valve 5. A part of the cylindrical portion 5c is extended in a radial direction to form the first pressure adjusting passage 61.

[0081]FIG. 5B also shows a cross sectional view of the cylindrical portion 5c of the first spool valve 5. Three parts of the cylindrical portion 5c are extended in radial directions to form multiple pressure adjusting passages 61.

[0082]FIG. 5C shows a vertical cross sectional view of the flow control valve 2, wherein the first pressure adjusting passage 61 is formed in the side wall portion 5d of the first spool valve 5.

[0083]FIG. 5D also shows a vertical cross sectional view of the flow control va...

third embodiment

[0086] A third embodiment will be explained with reference to FIG. 6.

[0087] The forward end 70 of the protruded small-diameter portion of the second spool valve 6 is formed into a semispherical shape, so that the ball 55 of the first embodiment can be eliminated. According to the third embodiment, the number of parts as well as number of assembling processes for the flow control valve can be reduced to realize a cost down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com