Autoclavable reclosable package

a technology of autoclavable and reclosable packages, which is applied in the field of packaging, can solve the problems of unsatisfactory bonding between polypropylene film and polyethylene film, unable to withstand the temperature requirements of the retort procedure, and resealable packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

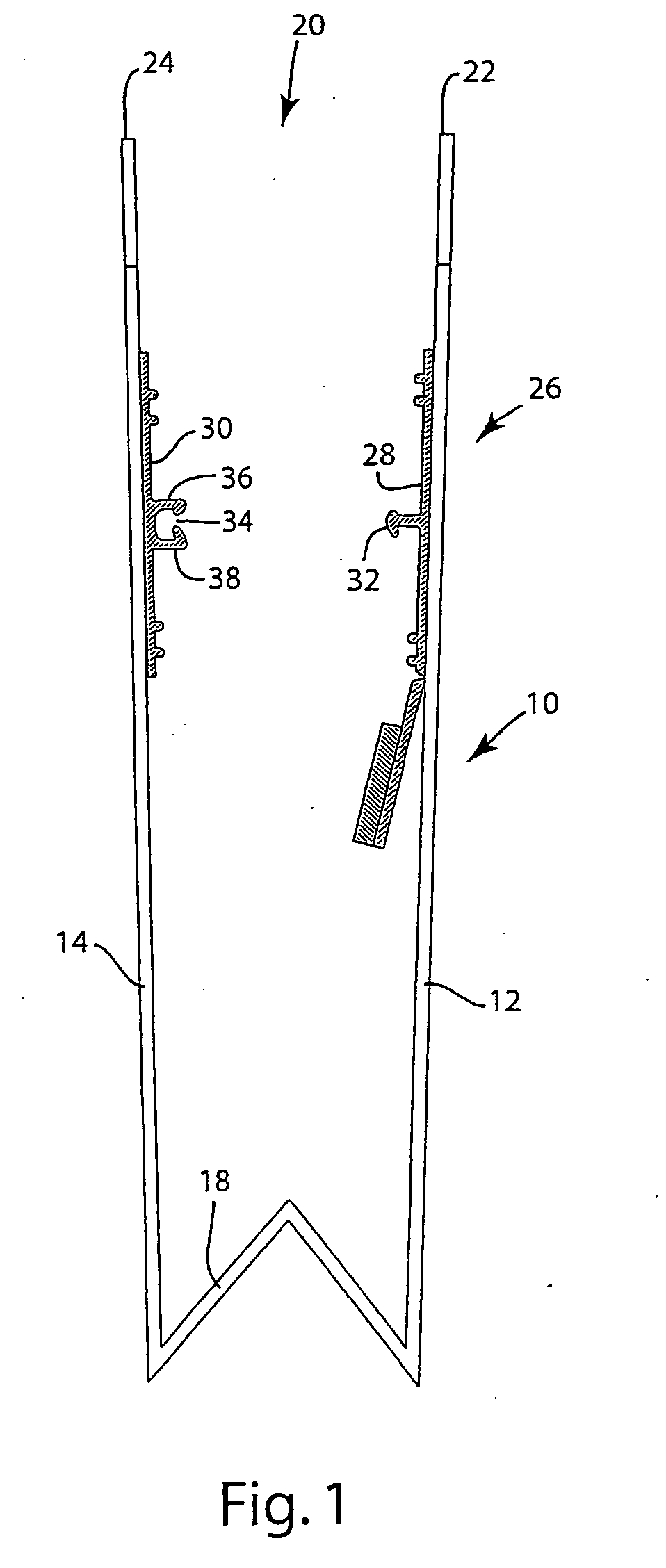

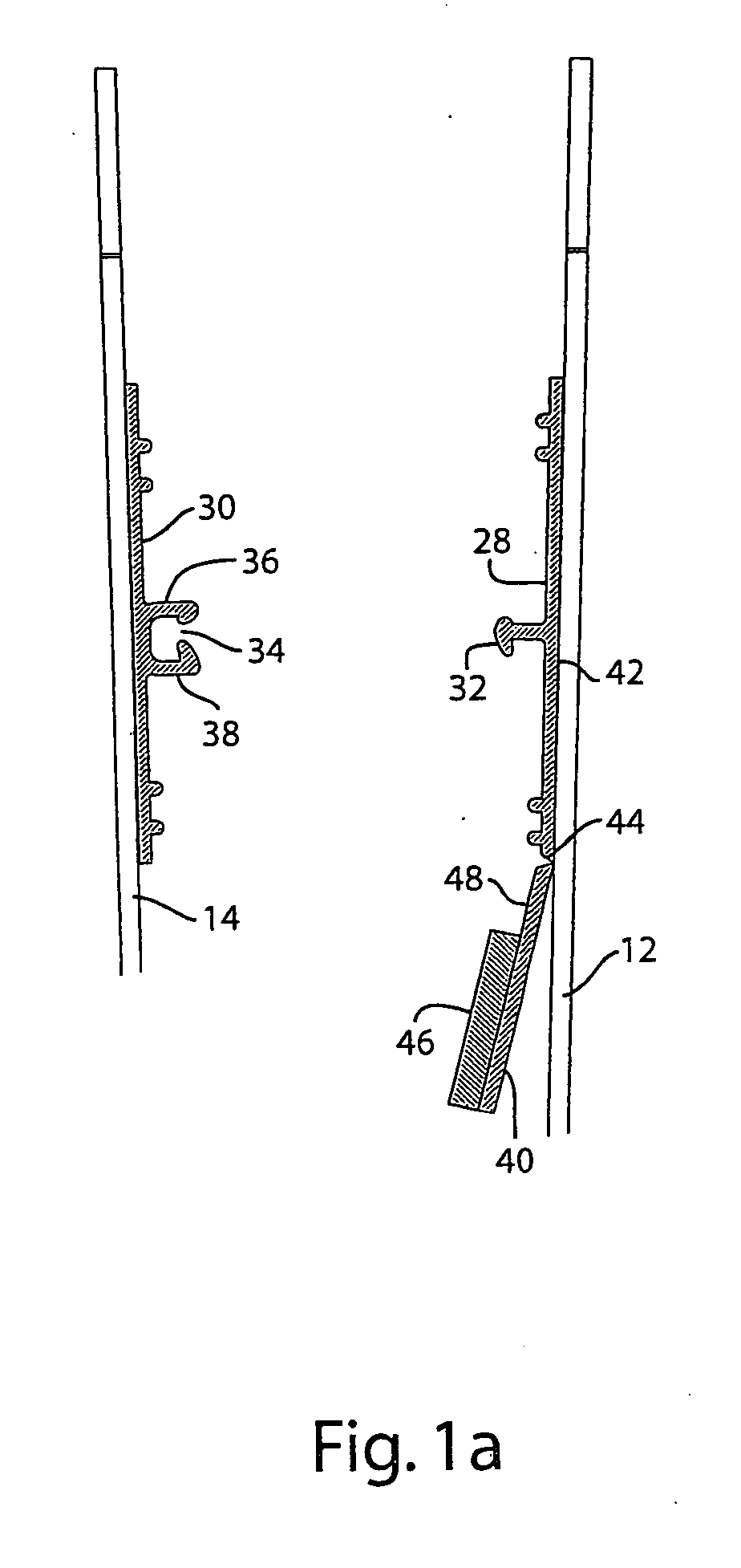

first embodiment

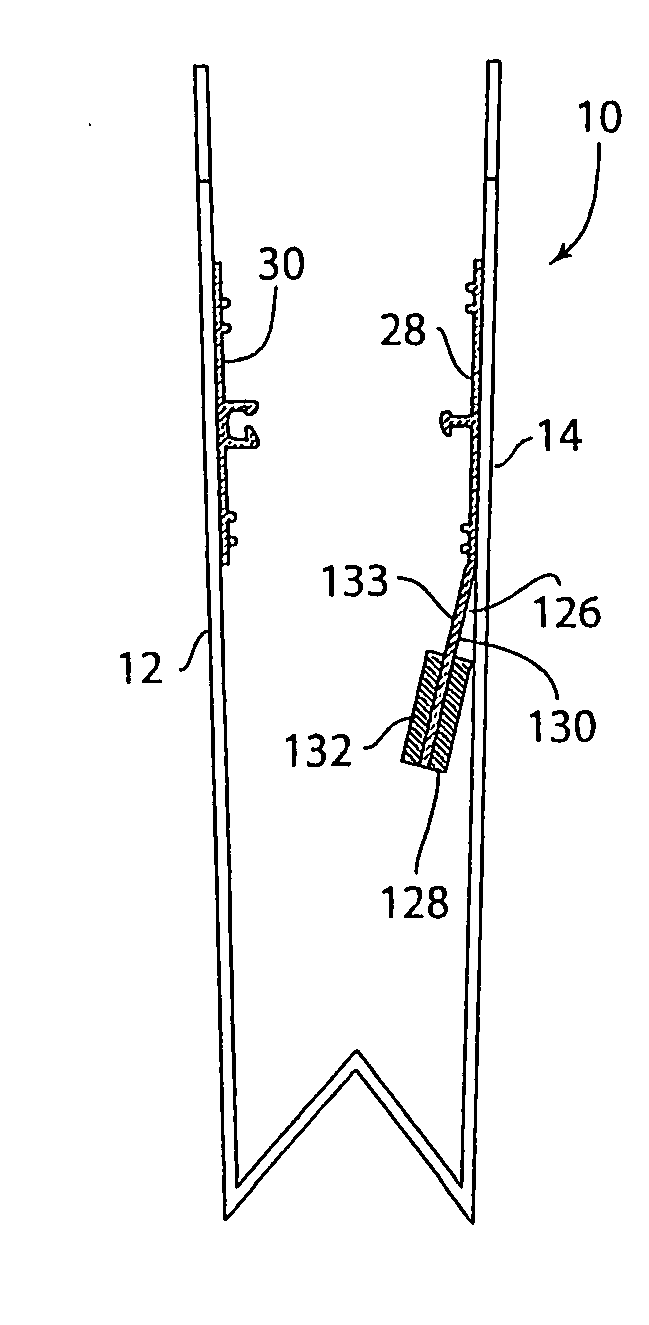

[0062] An important consideration for the sealant 46 in the invention is that the sealant is able to provide a hermetic seal between the sealing flange 40 and the side panel 14 yet withstand the retort procedure. Typically, the retort procedure occurs at 255° F. for the required period of time to cook the food product while it is in the package. The retort procedure may last as long as 84 minutes or more. During the autoclave and sterilization procedures, the sealant must maintain its integrity and remain attached to the side panel 14 to provide a hermetic seal.

[0063] As illustrated in FIG. 3, when the sealing flange 40 is attached to the side panel 14, the product 50 within the open enclosure can be subjected to the retort procedure. During this procedure, the product 50 is cooked in the package and harmful bacteria or other contaminants are killed. This type of retort procedure is typically associated with fresh food products, such as tuna or other perishable items.

[0064] In acco...

second embodiment

[0072] Referring now to FIG. 6, thereshown is an alternate embodiment of the male closure profile 28. In the second embodiment, the sealing flange 62 has a semi-circular configuration and includes a pair of die lines 64 and 66. The sealing flange 62 is attached to the attachment flange 42 and separates from the attachment flange 42 when the product package 10 is opened for the first time.

[0073] As can be seen in FIG. 6a, the sealant 46 is applied to the outer end 68 of the sealing flange 66 and contacts the side panel 14 to form a hermetic seal between the sealing flange 62 and the side panel 14. In the embodiment of the invention illustrated in FIG. 6, the sealant 46 and the closure profiles 28 and 30 are formed from the same material illustrated and described in FIGS. 1-5.

[0074] Referring now to FIGS. 7a-7b thereshown is another alternate embodiment for the zipper closure to be used across the open mouth 20 of a product package that can be subjected to the retort process. The zip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com