Seal cavity throat protectors

a throat protector and sealing technology, applied in leakage prevention, liquid fuel engine components, non-positive displacement fluid engines, etc., can solve the problems of increased pressure difference, increased difficulty of penetration, and increased sealing resistance, so as to maximise the effect of centrifugal motion and increase the sealing effect of the sha

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

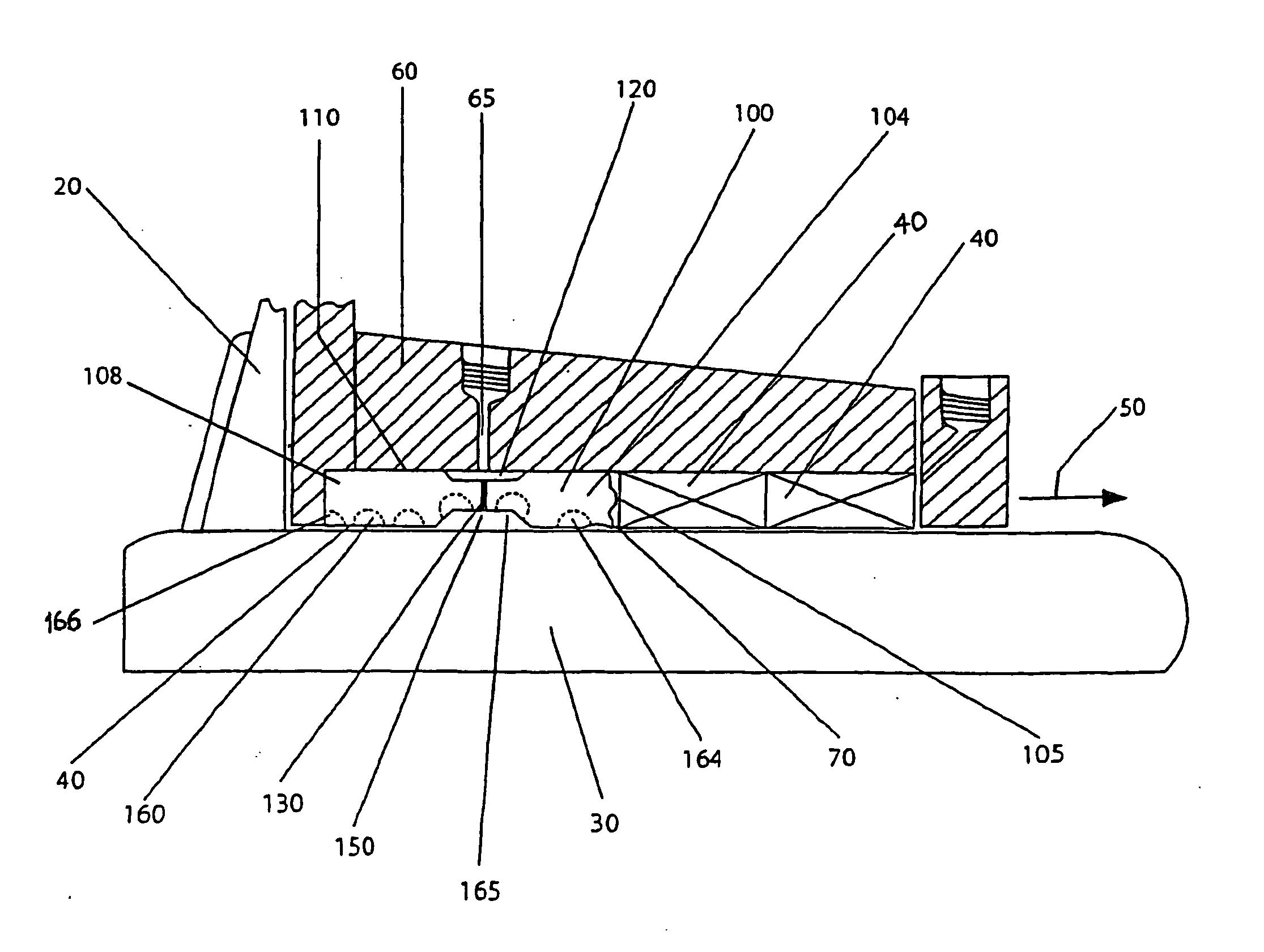

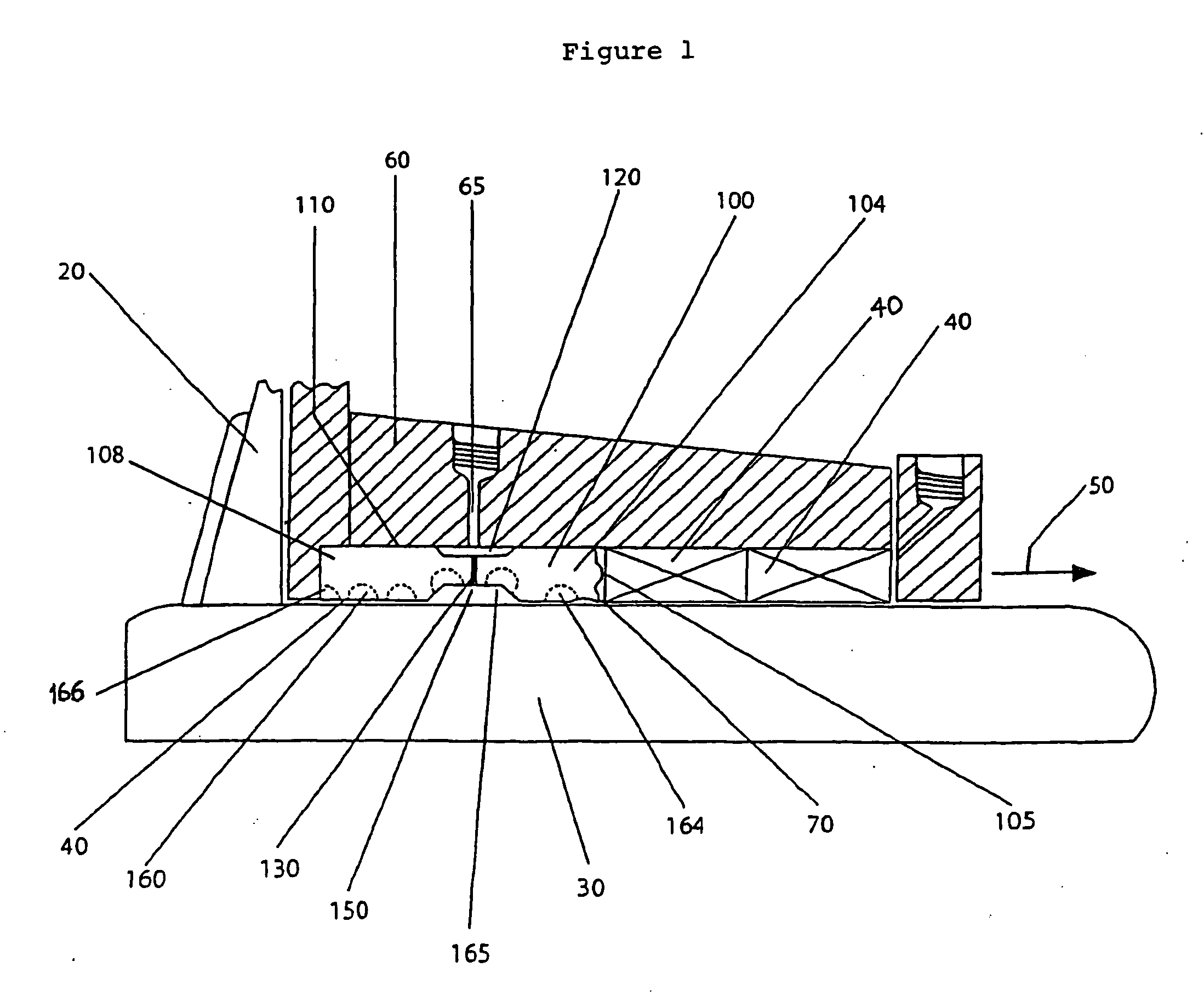

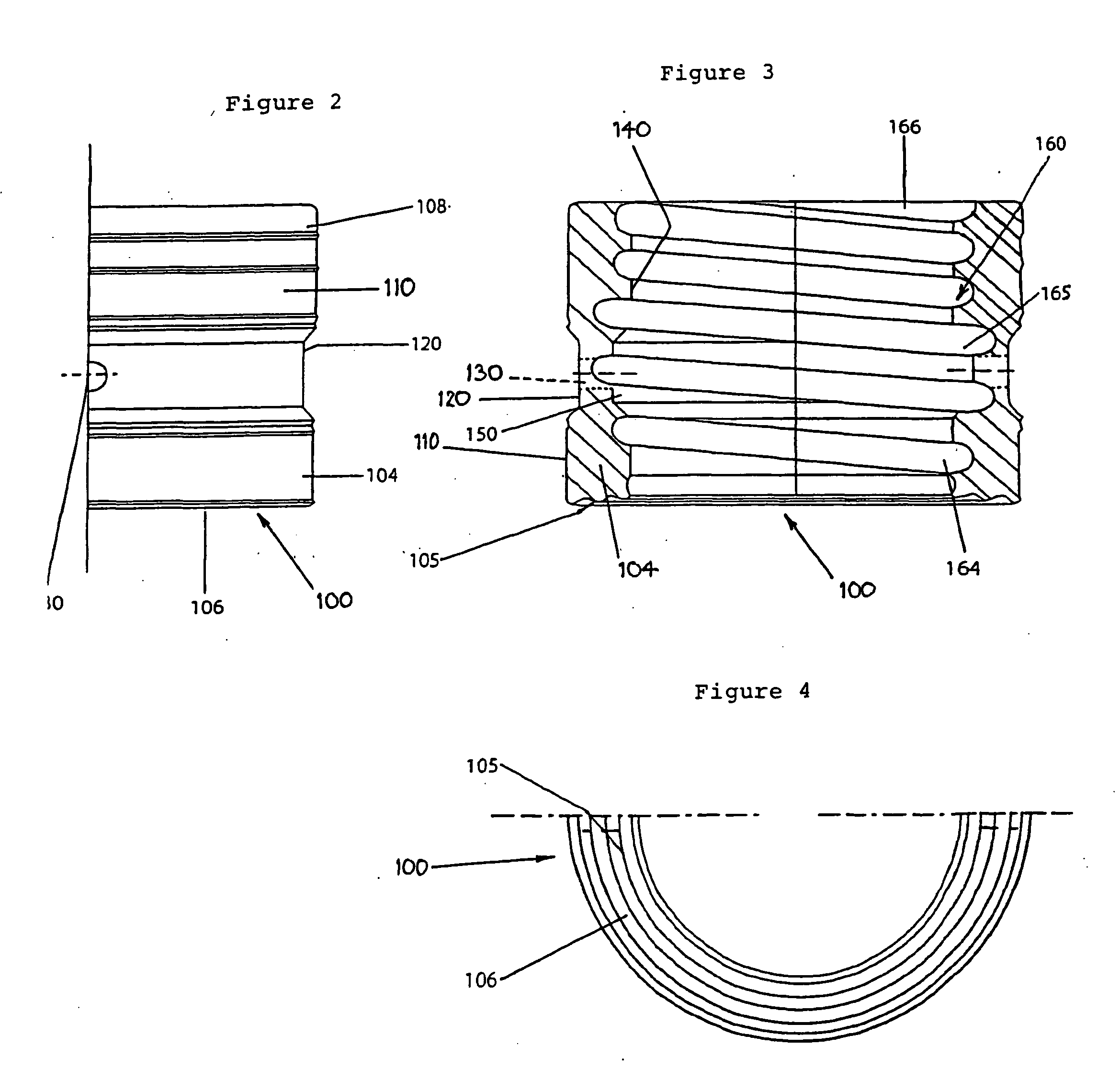

[0047]FIG. 1 depicts a typical environment for a seal cavity throat protector in the form of a bushing according to the present invention which is shown generally at 100. The environment includes an operative portion such as an impeller 20, which is connected to a shaft 30, the shaft 30 being connected to a prime mover such as a motor 40 (not shown). Seals 40 protect bearings which support the shaft which would be further along the shaft in the direction of arrow 50. Shaft 30 together with shaft housing 60 and seals 40 form a seal cavity shown generally at 70.

[0048] Bushing 100 has a seal portion 104 adapted to surround the shaft and to engage a seal 40, and an open portion 108 adapted to surround the shaft and to define with the shaft a passageway for ingress and egress of material. Bushing 100 has an outer surface 110 with a circumferential indentation 120, into which a bore 65 through shaft housing 60 empties. Bushing 100 further has a bore 130 which runs from outer surface 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com