Composite lintel system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

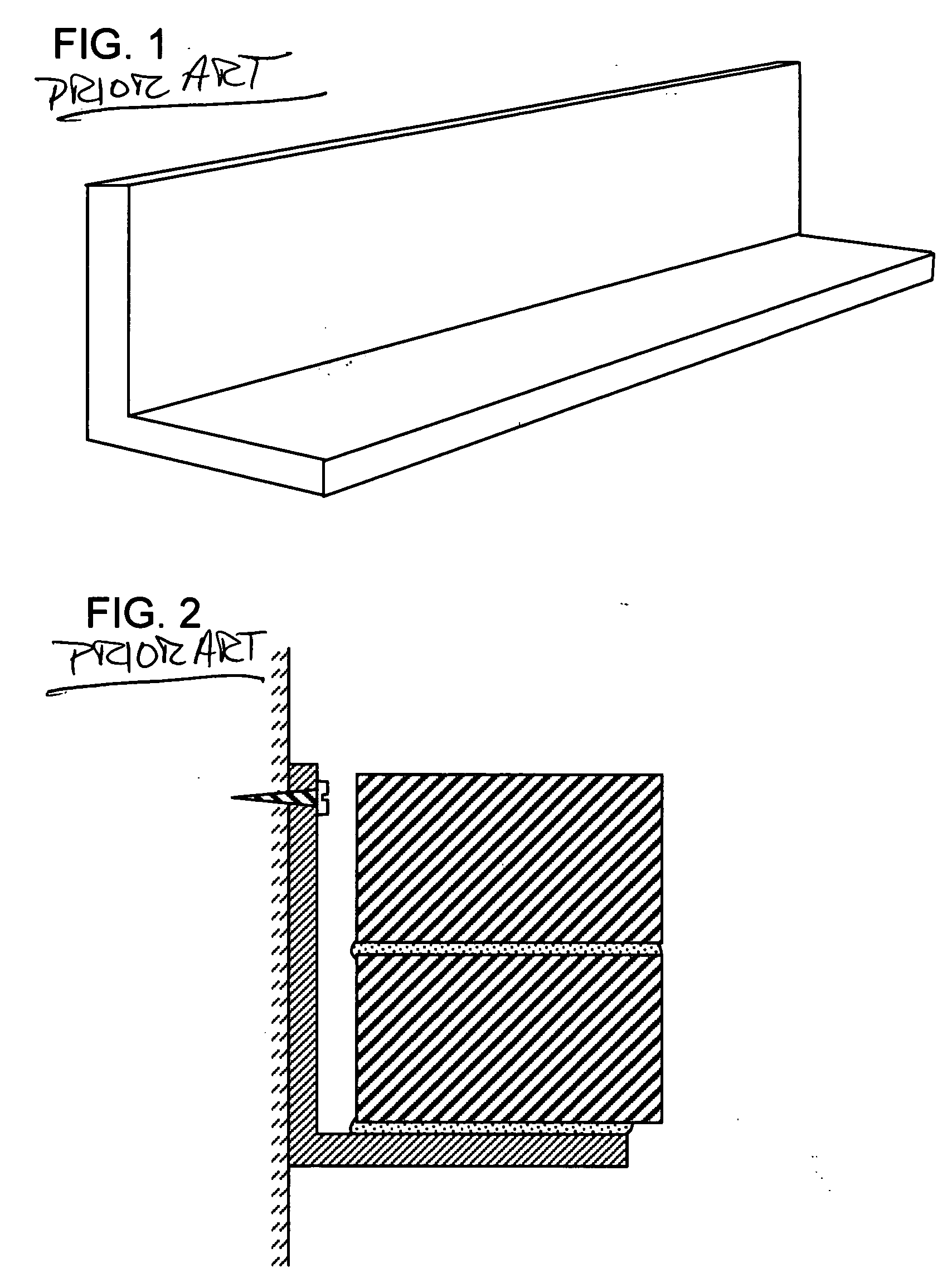

[0057] Referring now to the figures where similar parts are numbered the same throughout. FIG. 1 is a perspective view of a typical embodiment of an angle iron used as a lintel in the prior art. As mentioned herein above, the angle iron typically comprises steel bar having an L-shaped cross-section. FIG. 2 shows the typical configuration of a prior art angle iron affixed to a building structure and having bricks and mortar supported thereon.

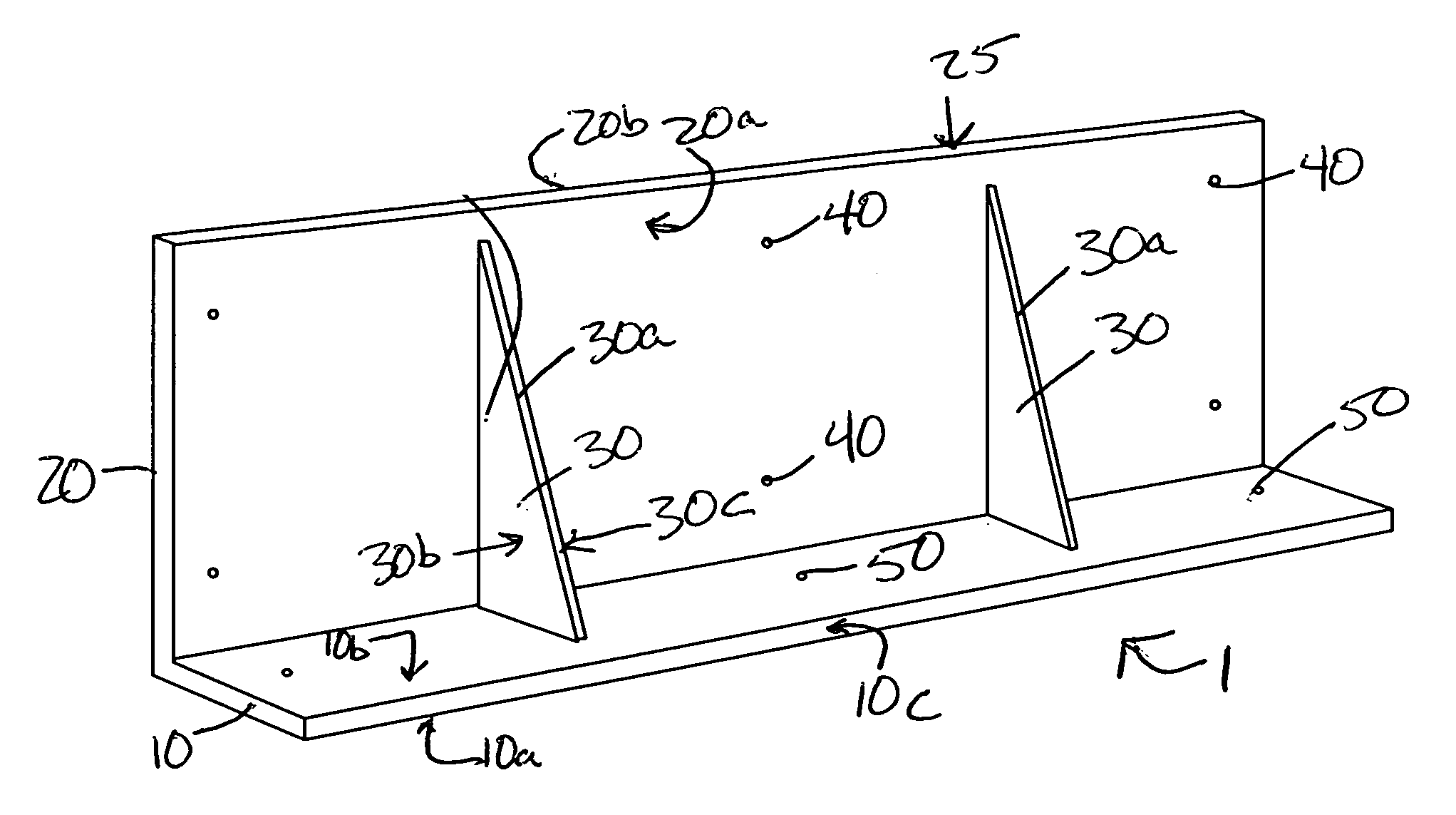

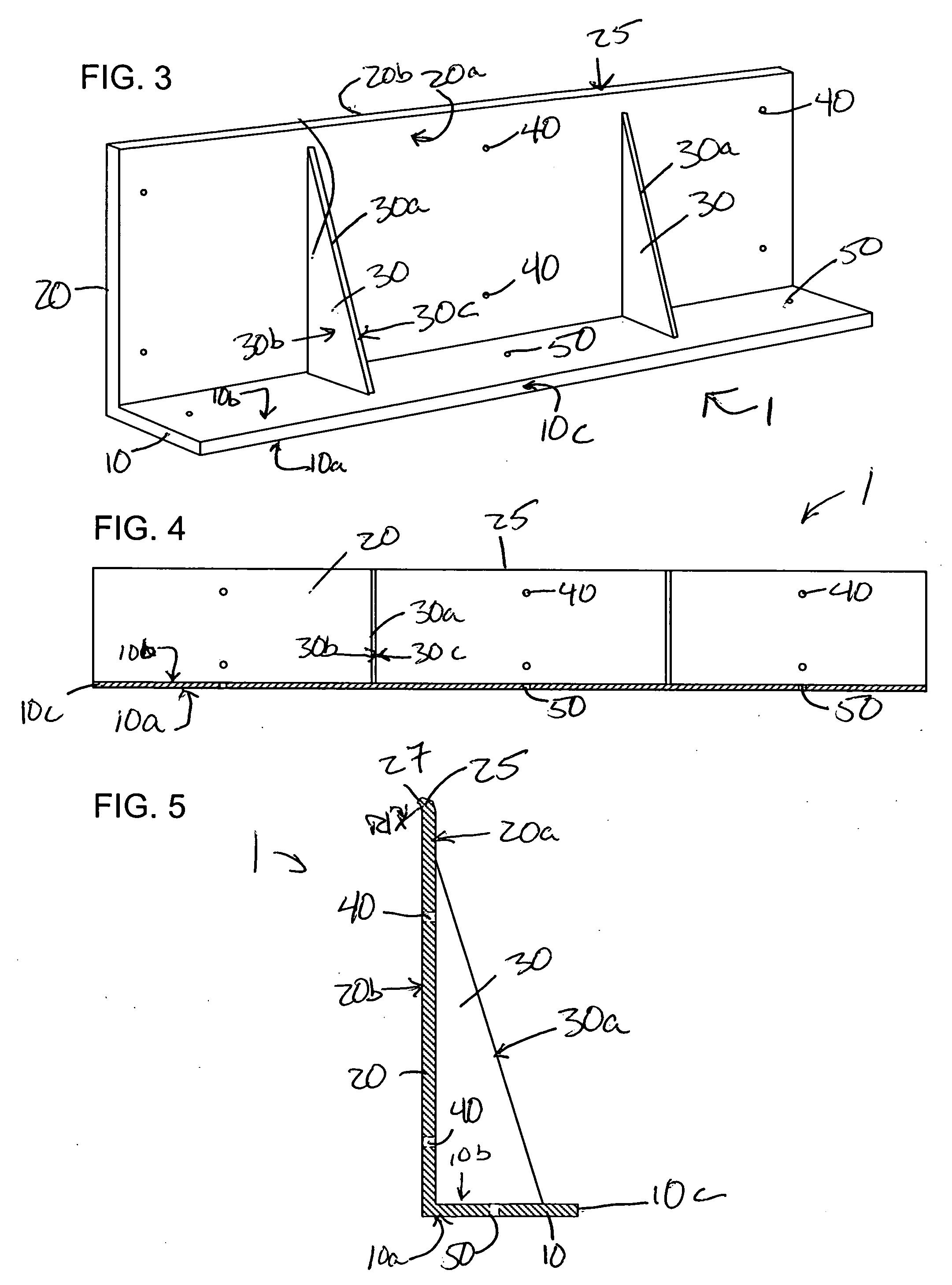

[0058] Referring now to FIGS. 3-5: FIG. 3 is a perspective view of the preferred embodiment of the invention. In this embodiment, the lintel 1 comprises a composite structure having a generally L-shaped cross-section. The lintel 1 has a vertical leg 20 which is affixed to the underlying structure (building header or frame above the opening) and which is rigidly attached to a horizontal leg 10, upon which bricks and mortar are laid.

[0059] The materials of construction of the vertical leg 20 and horizontal leg 10 of the lintel 1 are preferably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com