Polymer-based molded article with minimal flame spread and smoke properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

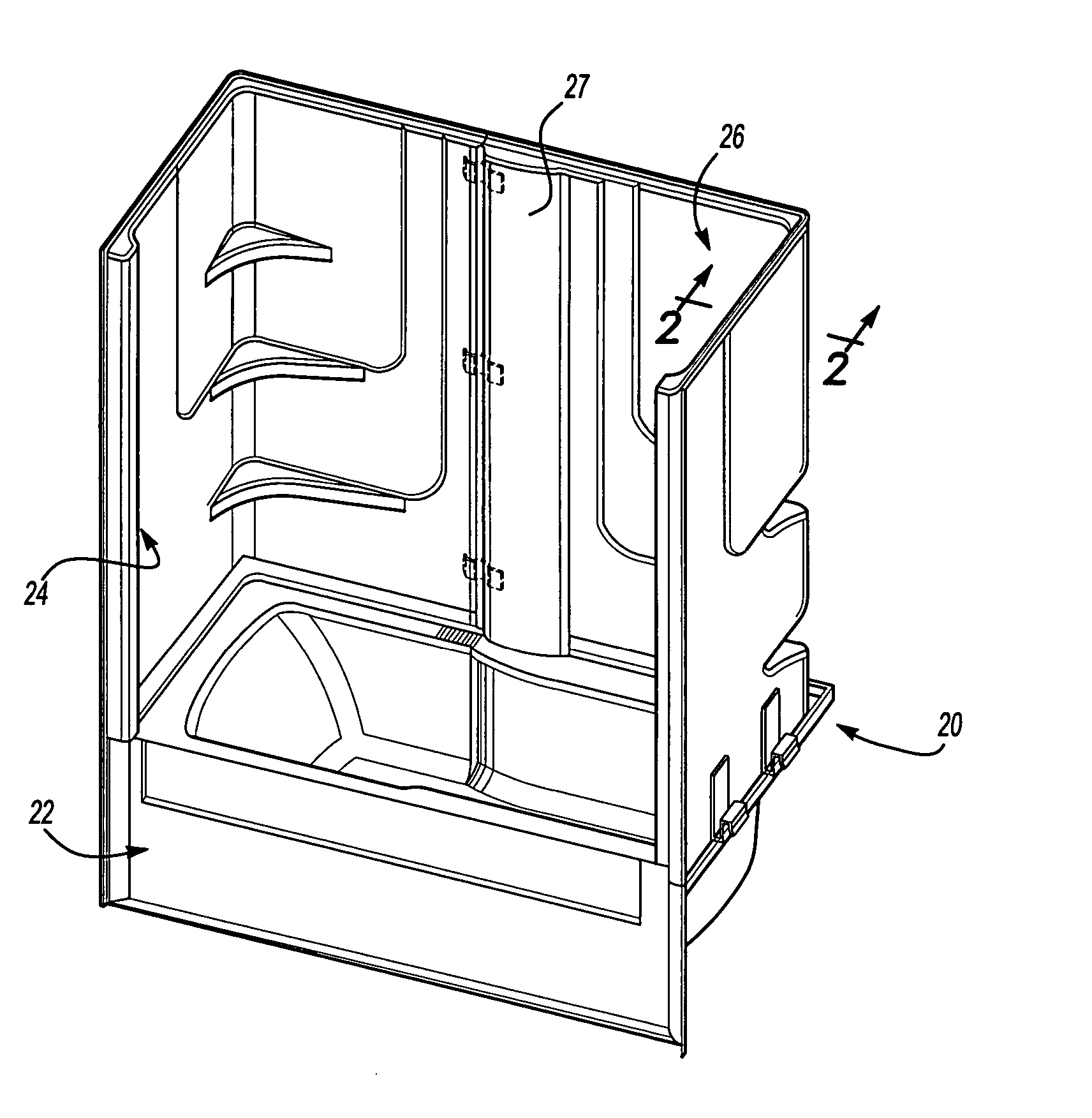

[0011]FIG. 1 illustrates a general perspective view of a polymer based molded article 20. The molded article 20 is preferably a tub and shower surround, which is formed of multiple portions. Generally, a tub portion 22 receives wall portions 24 and 26 to form the molded article 20. It should be understood that any number of molded articles of any number of portions, such as shower bases, sinks, or other plastic faced components, will benefit from the present invention. Preferably, such components are relatively large bathroom-related fixtures.

[0012] Referring to FIG. 2, a sectional view through one of the portions 22, 24, 26 is illustrated. It should be understood that the sectional view may be taken anywhere within the portions 22, 24, 26. Each portion 22, 24, 26 preferably includes at least three layers: a cosmetic surface layer 28, an intermediate layer 30, and a backing layer 32.

[0013] Typically, each layer 28, 30, 32 is sprayed, in order, onto an open mold to build up the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy | aaaaa | aaaaa |

| Aliphatic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com