Mold resistant exterior wall assembly

a technology for exterior walls and assemblies, applied in the direction of building components, building insulations, ceilings, etc., can solve the problems of affecting health, affecting the energy efficiency of building structures with steel studs, and affecting the health of building materials, and a significant number of mold, mildew and fungus problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

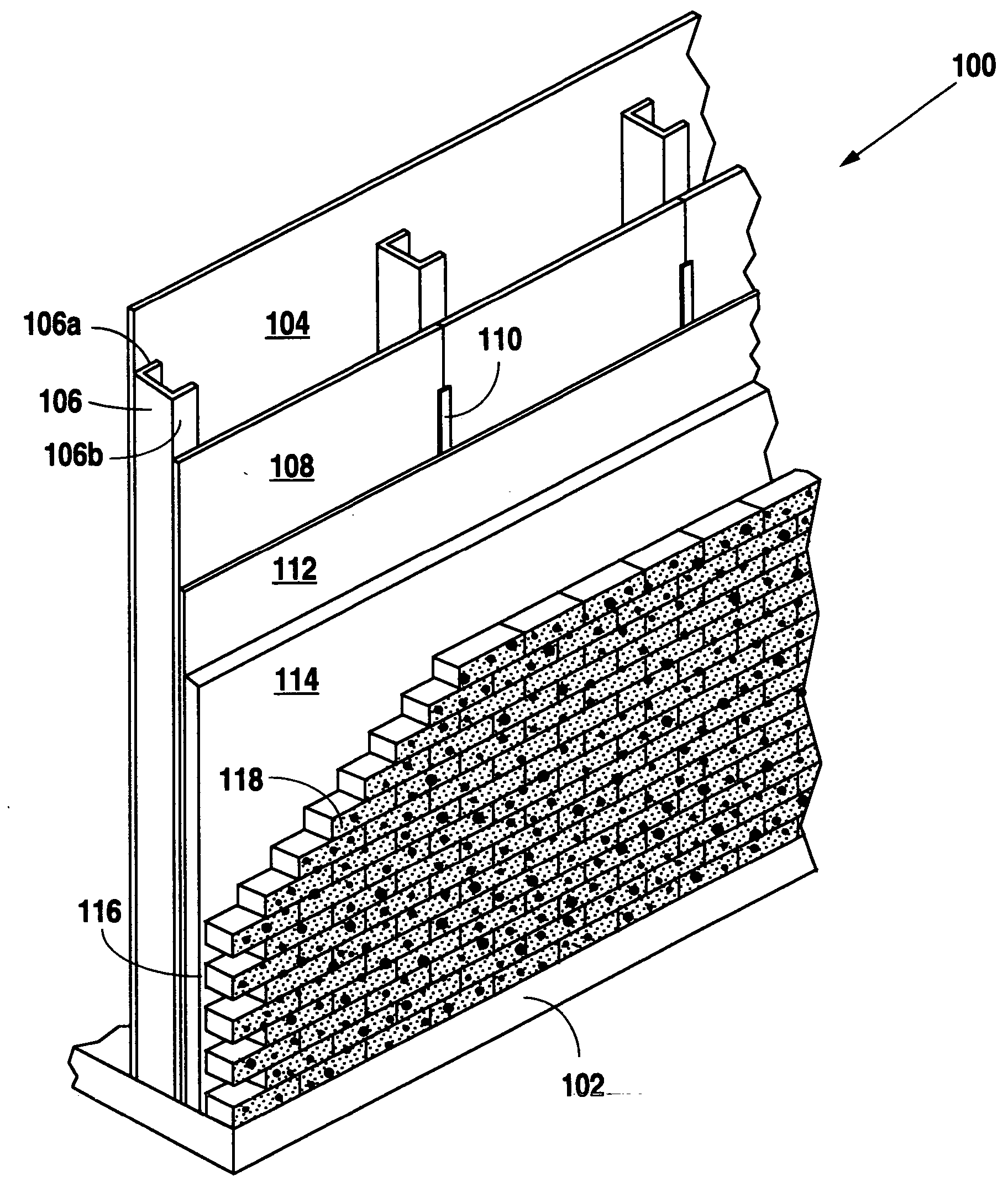

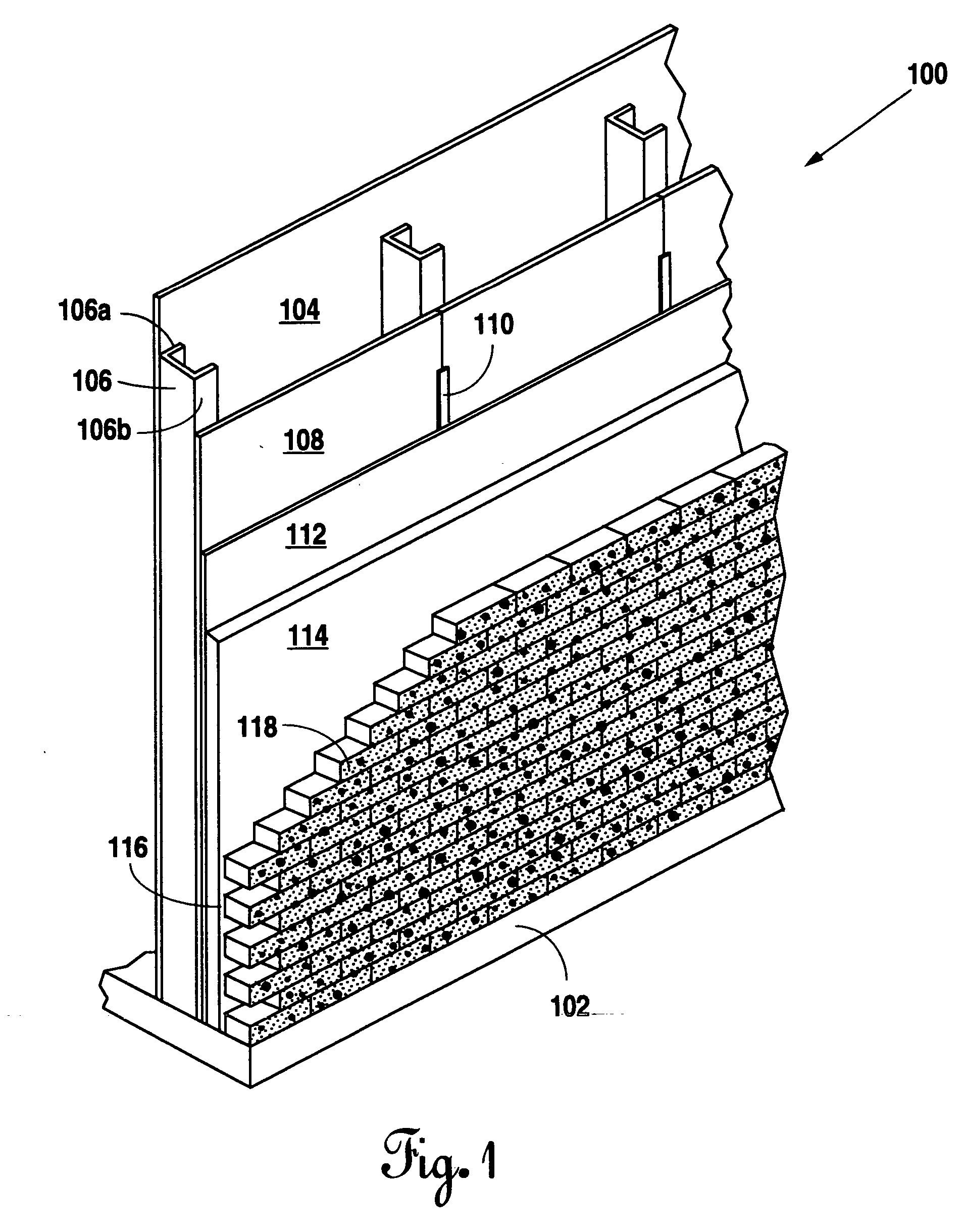

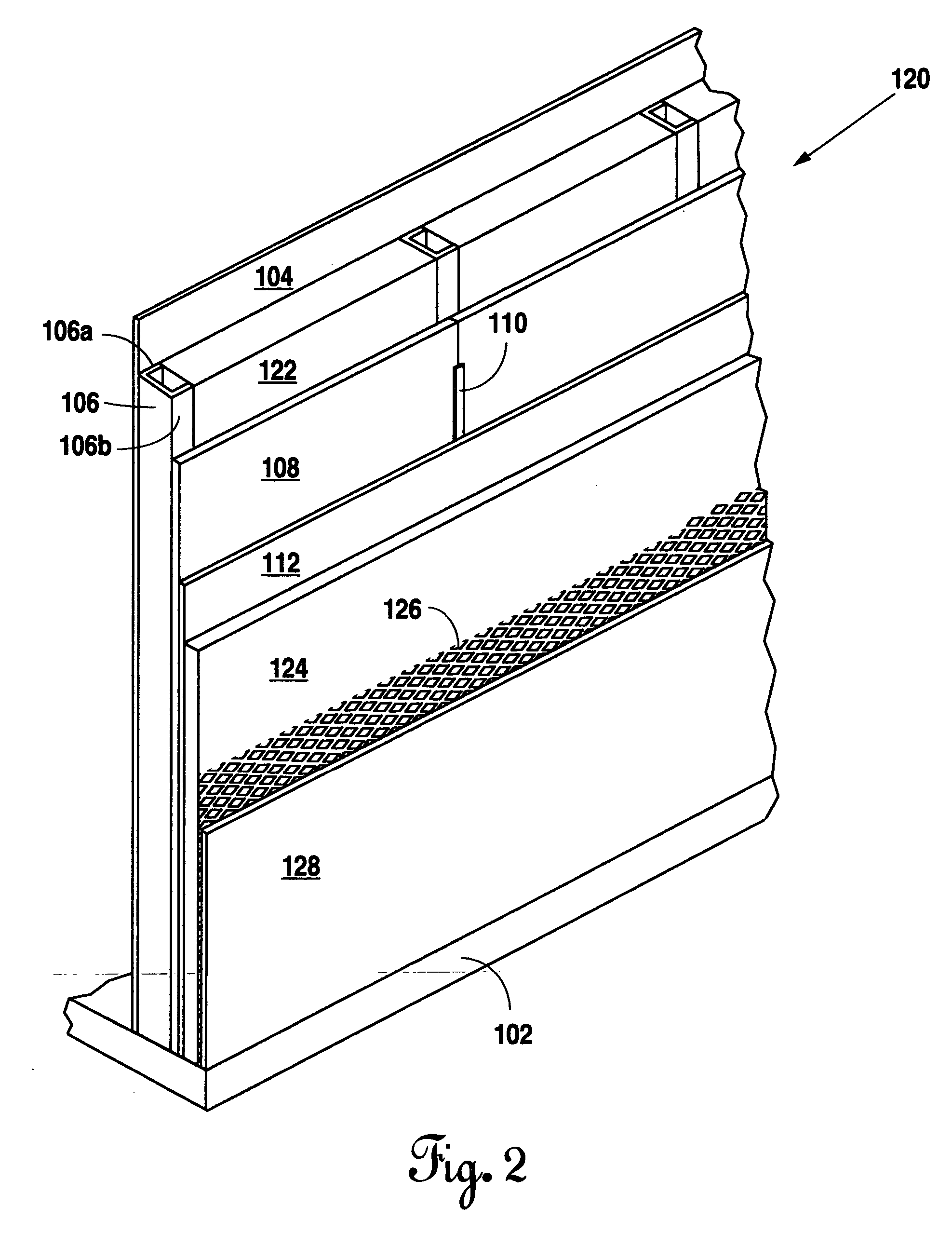

[0020] In FIG. 1, a perspective view of the preferred embodiment of the present invention is shown. More particularly, this preferred embodiment shows a mold resistant steel stud masonry veneer wall system 100. A foundation 102 is provided upon which the wall system 100 is assembled. The foundation 102 can consist of a crawlspace construction or slab-on-grade. A crawlspace foundation is a shallow and uninhabitable area between the soil and the first floor of the building. A crawlspace usually extends below the frost line or to a stable substrate. Crawlspaces are generally constructed with foundation walls and footings, however, piers may be used when the crawlspace is above grade. A slab-on-grade foundation is a concrete slab that is poured directly at ground level and acts as the first floor sub-surface. The slab is usually supported by continuous footing, piers or piles and grade beams.

[0021] Once the foundation 102 is in place, steel studs 106 are attached to the foundation 102....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com