Solenoid plunger cushioning system for a washing machine balancing fluid valve

a technology of balancing fluid valve and plunger, which is applied in the field of valves, can solve the problems of repeated operation of this type of solenoid and is extremely hard on the internal components of the solenoid, and achieve the effects of reducing the effect, reducing the voltage, and ensuring the effect of fluid dispensed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

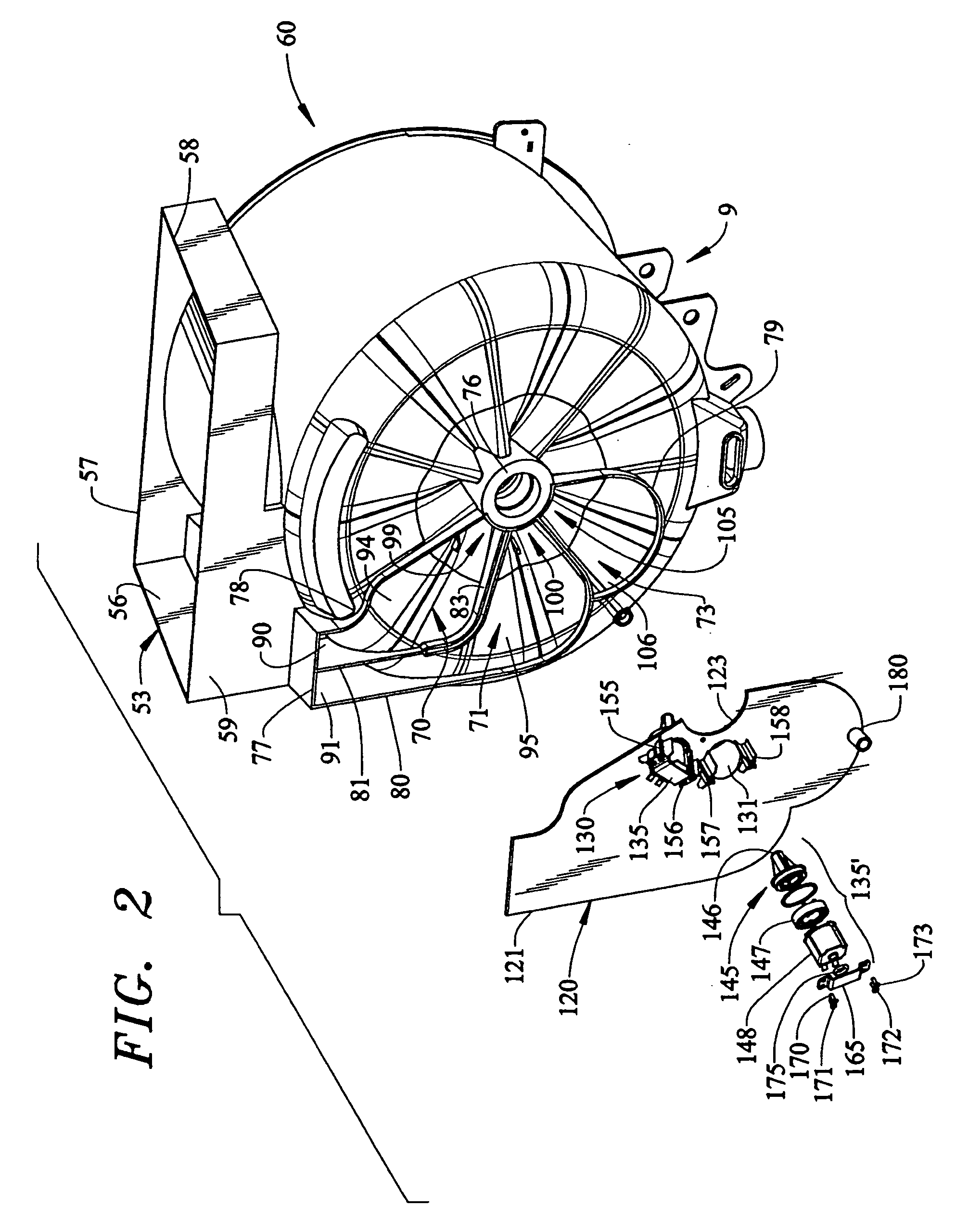

[0029] With initial reference to FIG. 1, a laundry appliance constructed in accordance with the present invention is generally indicated at 2. As shown, laundry appliance 2 constitutes a horizontal axis machine including an outer cabinet shell 4 having an associated door 6 which can be selectively opened to expose a washing basket 8. In the embodiment shown, washing basket 8, also referred to as an inner tub or spinner, is mounted within an outer tub 9 (FIG. 2) in cabinet shell 4 for rotation about an axis which is angled slightly downward toward a rear portion of cabinet shell 4. For the sake of completeness, inner tub 8 is shown to include a plurality of holes 10, as well as various generally triangular shaped and radially inwardly projecting fins or blades 12 which are fixedly secured to an internal peripheral portion of inner tub 8. In a manner known in the art, inner tub 8 is adapted to rotate during both wash and rinse cycles, such that articles of clothing placed therein actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com