Damper assembly and washing machine using the same

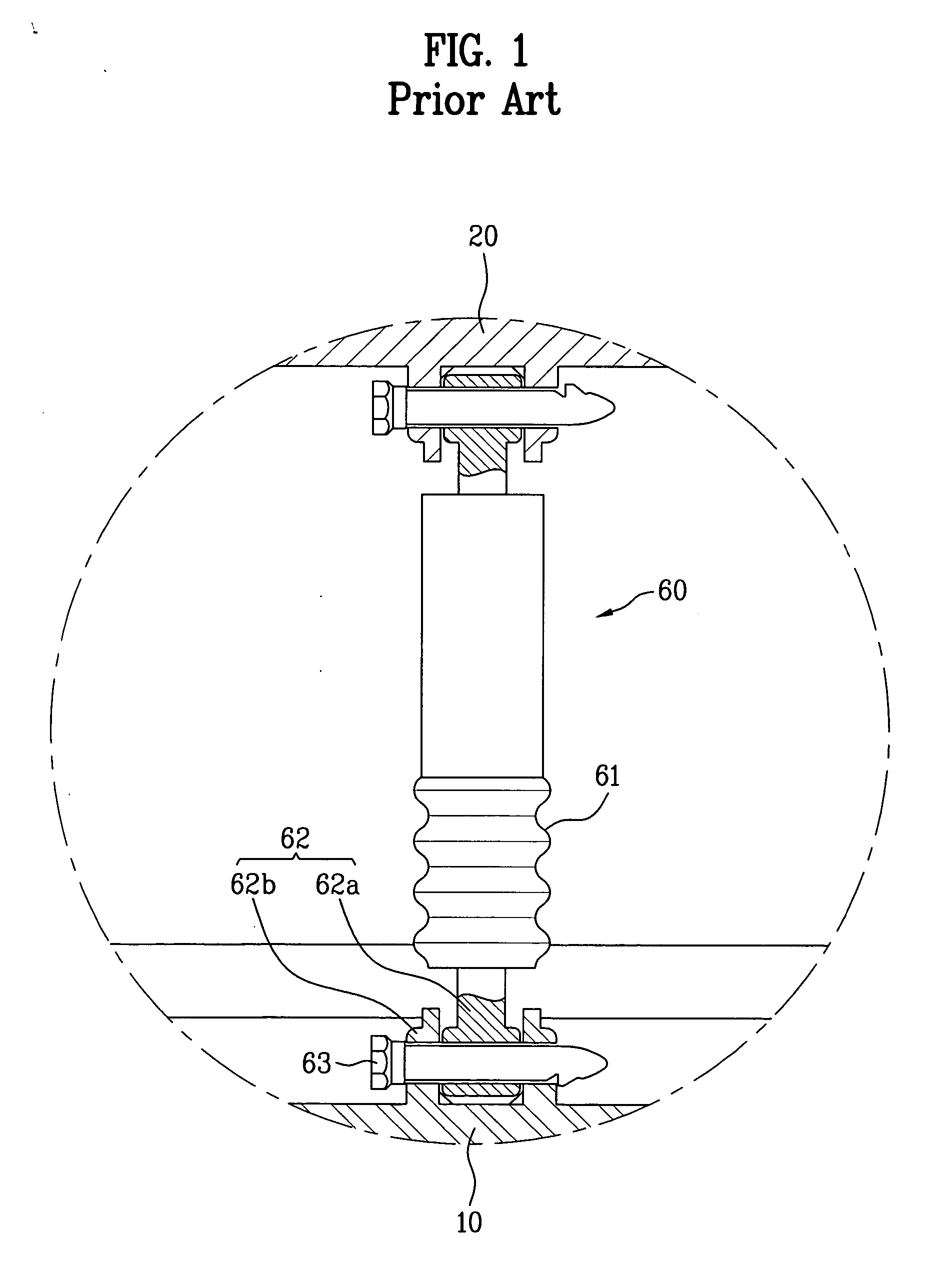

a technology of damper assembly and washing machine, which is applied in the direction of washing machine with receptacles, shock absorbers, plastic/resin/waxes insulators, etc. it can solve the problems of bringing about the washing effect of beating and rubbing, the damper assembly as described above is difficult to be assembled to the tub and cabinet, and the pins tend to be abraded, so as to facilitate assembly work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Throughout the drawings, like elements are indicated using the same or similar reference designations where possible.

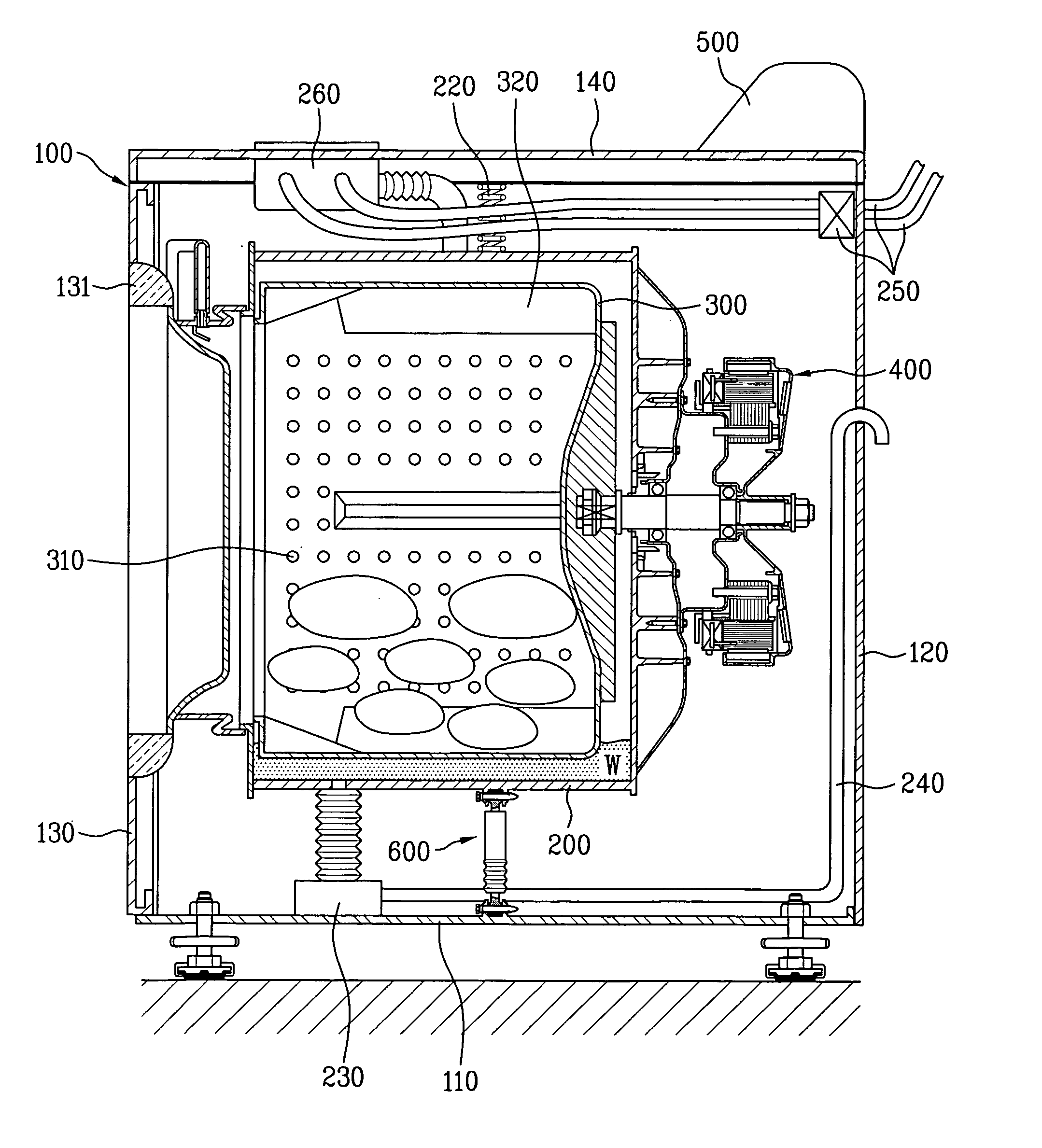

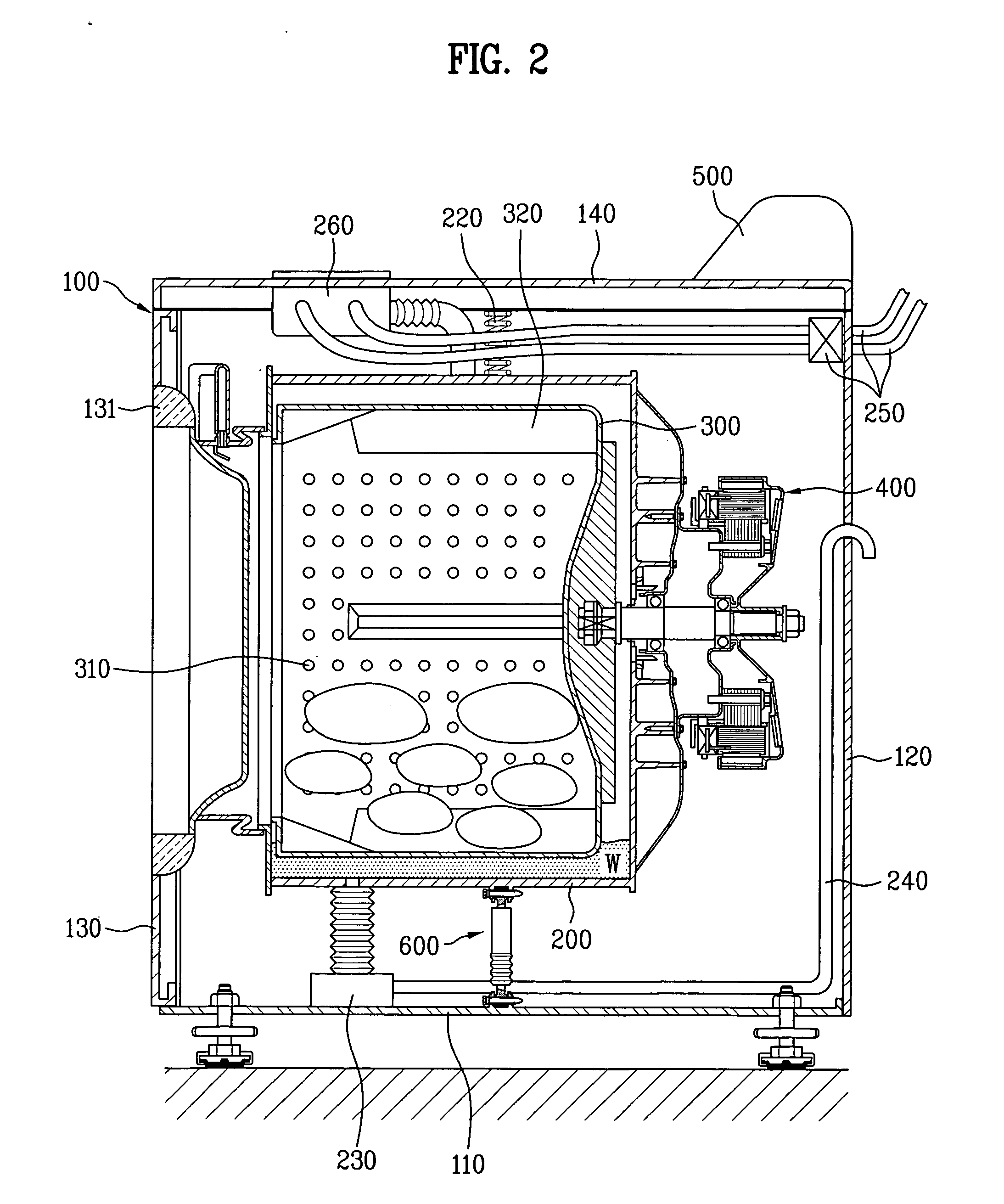

[0026] First of all, FIG. 2 is a cross-sectional diagram of a washing machine having a damper assembly according to the present invention and FIG. 3 is a cross-sectional diagram of a damper assembly according to the present invention. Referring to FIGS. 2 and 3, a drum type washing machine according to one embodiment of the present invention includes a cabinet 100 forming an exterior, a tub 200 provided within the cabinet 100, a drum 300 rotatably provided within the tub 200, and a rotating means 400 for rotating the drum 300. The cabinet 100 includes a base plate 110 provided to a bottom side, a pair of side plates (not shown) provided to both sides of the base plate 110, respectively, a rear plate 120 pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical energy | aaaaa | aaaaa |

| drive force | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com