Residential construction method and apparatus

a technology for residential construction and construction methods, applied in the field of residential construction, can solve the problems of unsuitable residential construction, cladding, and eps foamed with air, and achieve the effect of sufficient strong roof and considerable thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

accompanied by the following drawings.

BRIEF DESCRIPTION OF THE SEVERAL VIEWS OF THE DRAWINGS

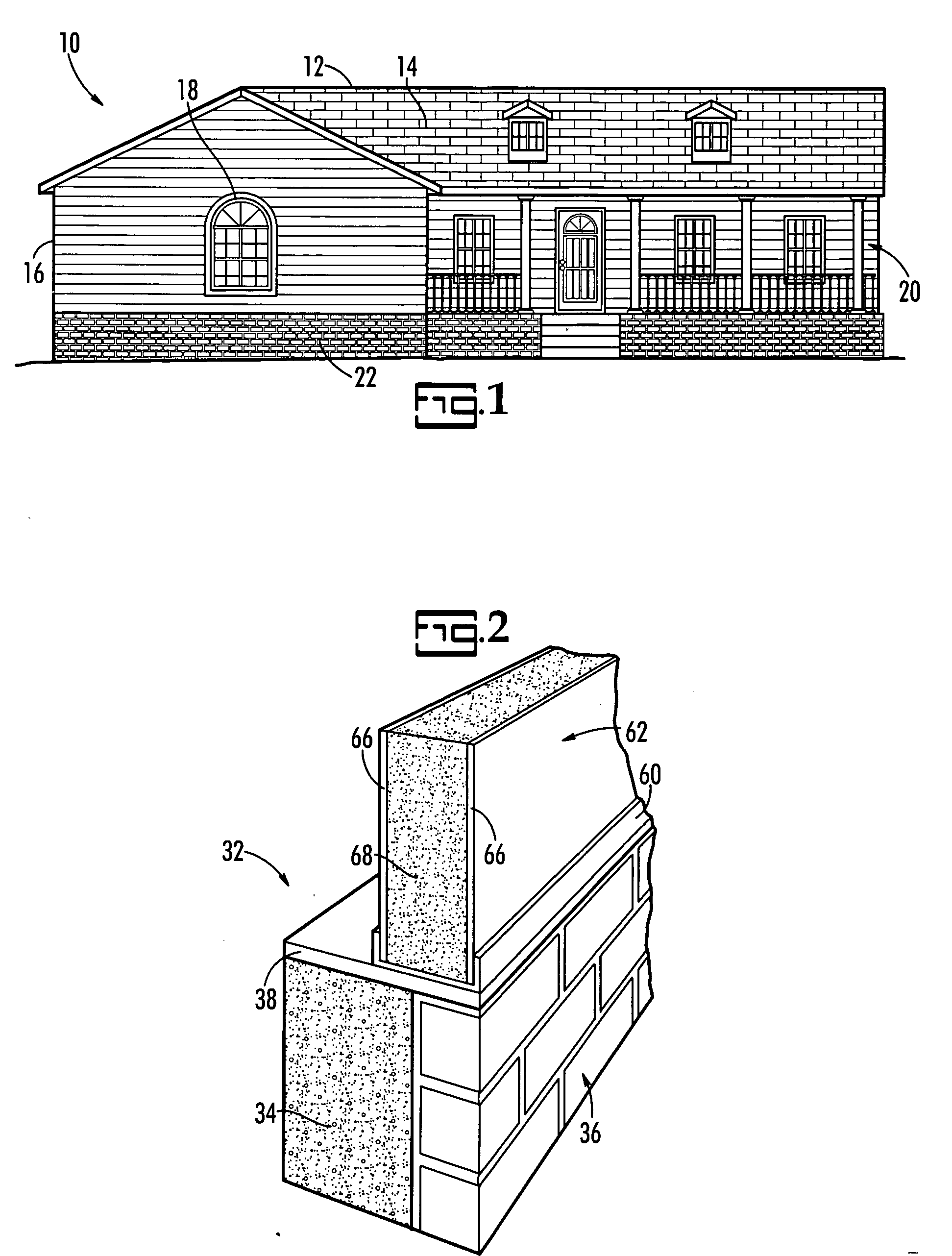

[0013]FIG. 1 illustrates a typical residence that can be made using the present construction methods or prior art methods;

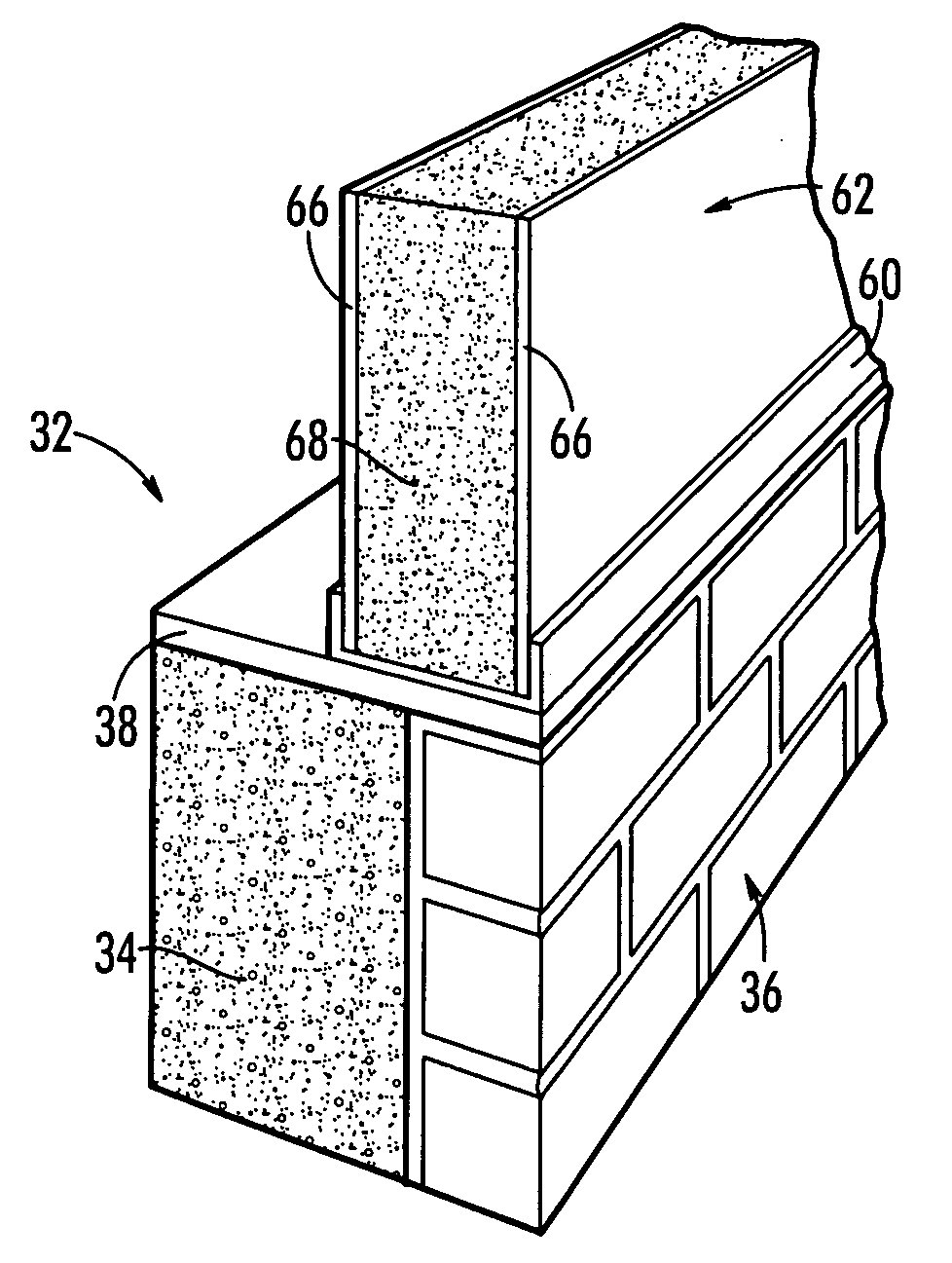

[0014]FIG. 2 illustrates a foundation and wall joint, according to a preferred embodiment of the present method;

[0015]FIG. 3 illustrates a support for a wall, according to a preferred embodiment of the present invention;

[0016]FIG. 4 illustrates a mid-floor support for a floor, according to a preferred embodiment of the present invention;

[0017]FIG. 5 illustrates a detailed portion of the roof joint at the roof peak, made according to a preferred embodiment of the present invention;

[0018]FIG. 6 illustrates a detailed portion of the roof and wall joint, made according to a preferred embodiment of the present invention; and

[0019]FIG. 7 illustrates a partially cut away view of the end of a roof, made according to a preferred embodiment of the present invention.

DETAILED D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com