Metal strip for interlocking floorboard and a floorboard using same

a technology of interlocking floorboards and metal strips, which is applied in the field of building boards making methods, can solve the problems of undesired joint gaps between boards, poor strength, and certain differences, and achieve the effect of not impairing mechanical connections, undesired joint gaps, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

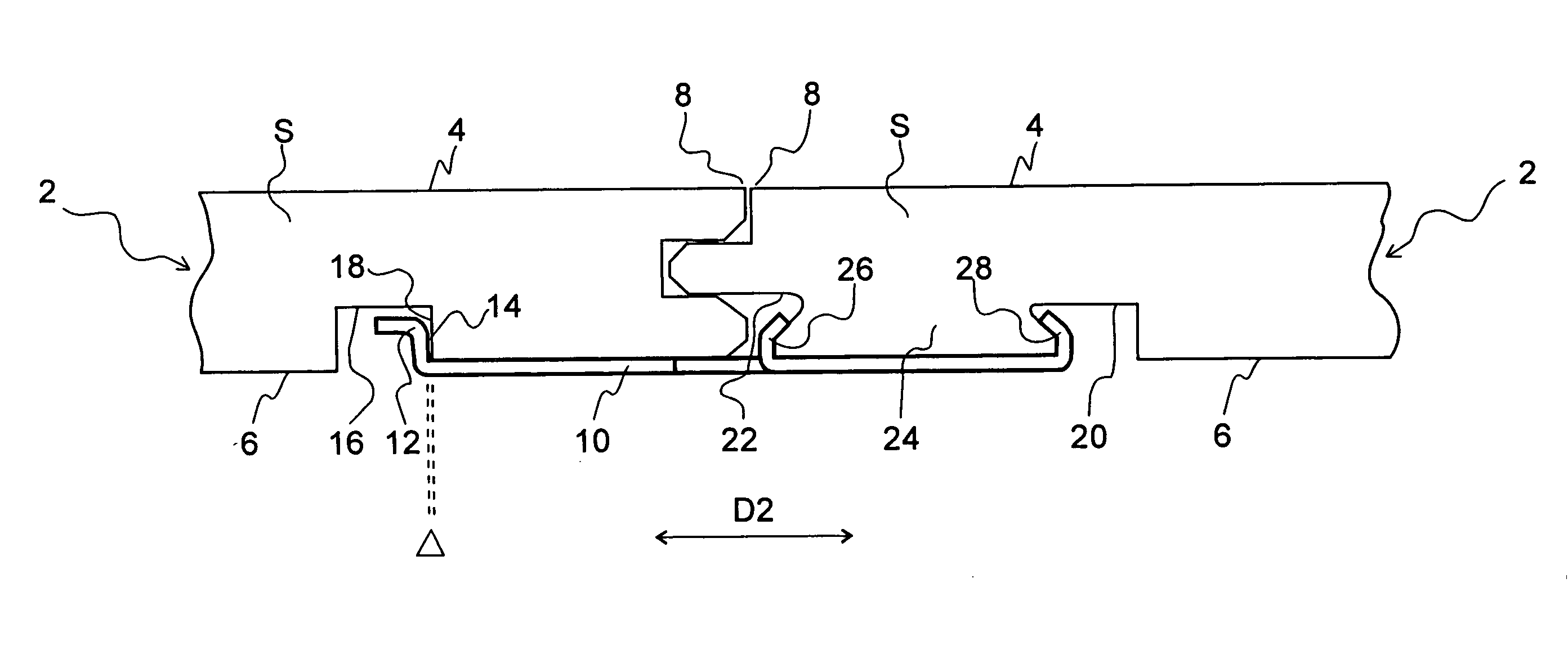

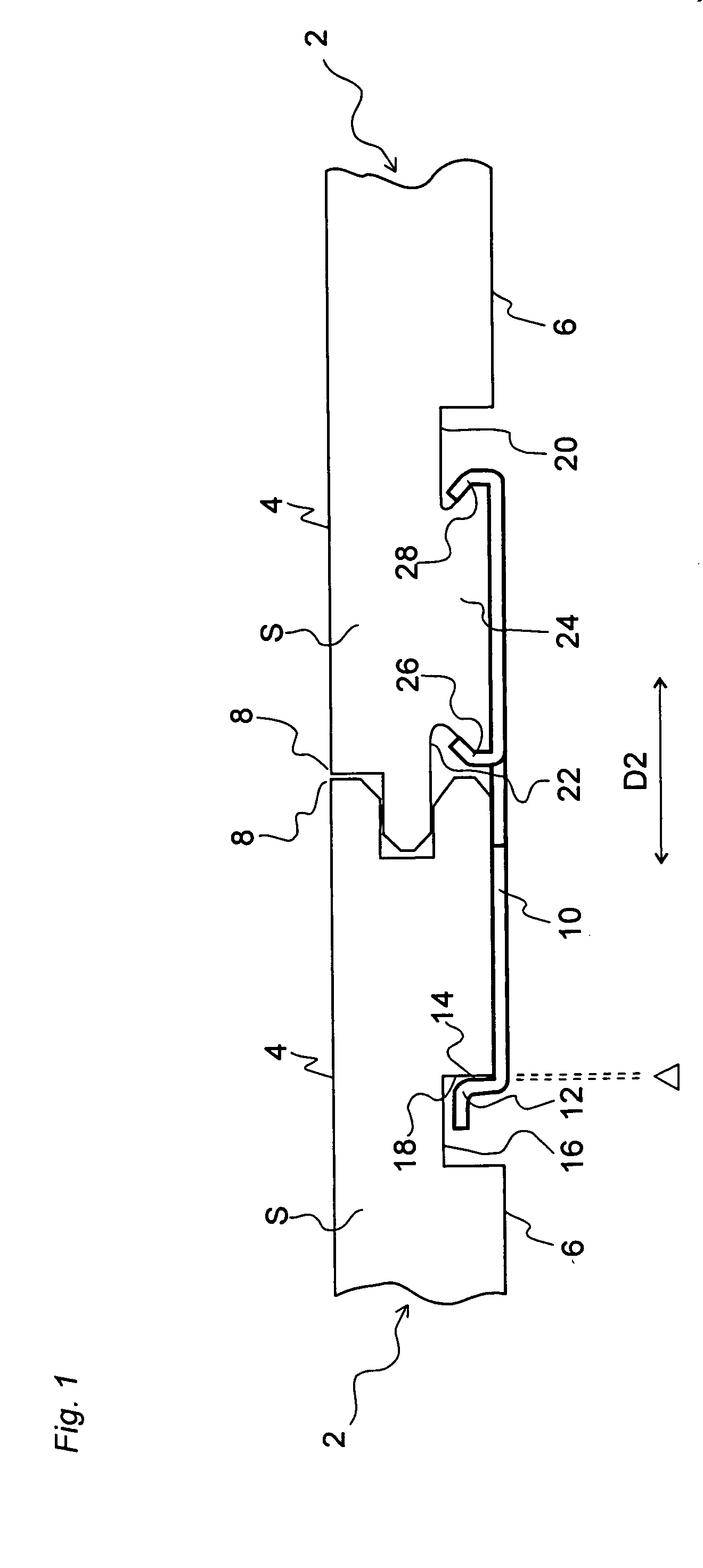

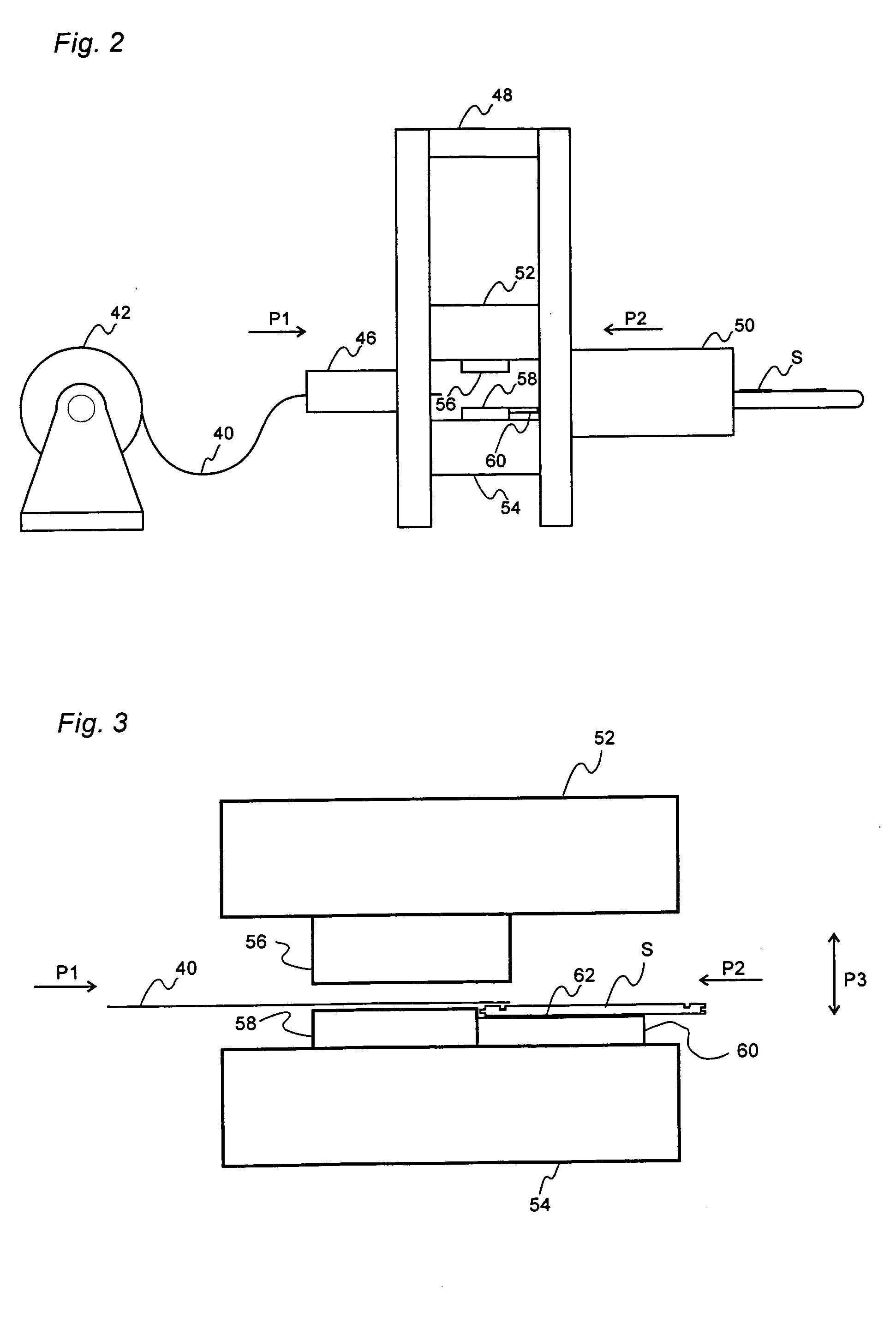

[0045] With reference to FIGS. 2-6 in the appended drawings, a production line will now be described, which is usable for making building boards, such as floorboards, of the type mentioned above with reference to FIG. 1 and in which production line an embodiment of the method according to the invention is implemented. The same reference symbols as in FIG. 1 will be used for the components of the floorboard.

[0046] In FIG. 2, a flexible, formable blank 40, preferably aluminium sheet, is wound onto a reel 42. The aluminium sheet 40 is fed from the reel 42 to a sheet feeder 46. The task of the sheet feeder 46 is gradually to feed (arrow P1) the flat blank 40 into a press 48. On its opposite side, the press 48 (arrow P2) receives machined (milled) bodies S of e.g. compact laminate from a board feeder 50.

[0047] In the production line in FIG. 2, the blank 40 is cut into separate metal strips 10, the locking elements 12 of the strips 10 are formed, and the strips 10 are mechanically attac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com