Hydrogen combustion heater

a combustion heater and hydrogen technology, applied in the direction of indirect carbon-dioxide mitigation, gaseous fuel burners, combustion processes, etc., can solve the problems of high thermal stress on the heat exchanger, too much formation of nitrogen oxides, and high combustion temperature caused by spark ignition, etc., to achieve stable heating capability and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The above-mentioned first combustion of the present invention can be limited to a mild oxidation, which is defined as being an oxidation free from firing of the hydrogen, by controlling the flow rate ratio of the air to the hydrogen. With this, it becomes possible to avoid explosion or deflagration and an excessively high combustion temperature. The flow rate ratio is preferably greater than 8:1, more preferably about 15.3:1, as will be described in detail hereinafter.

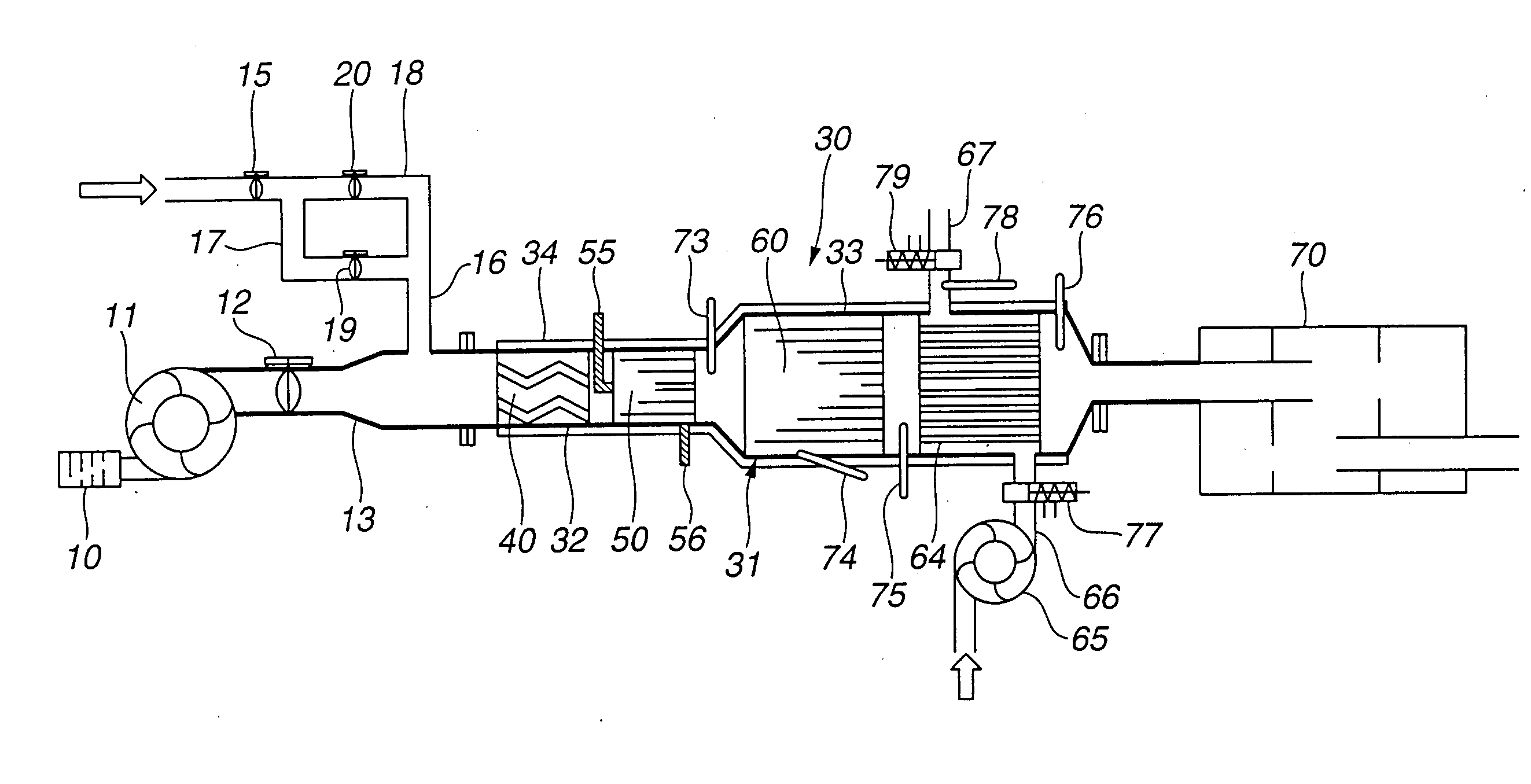

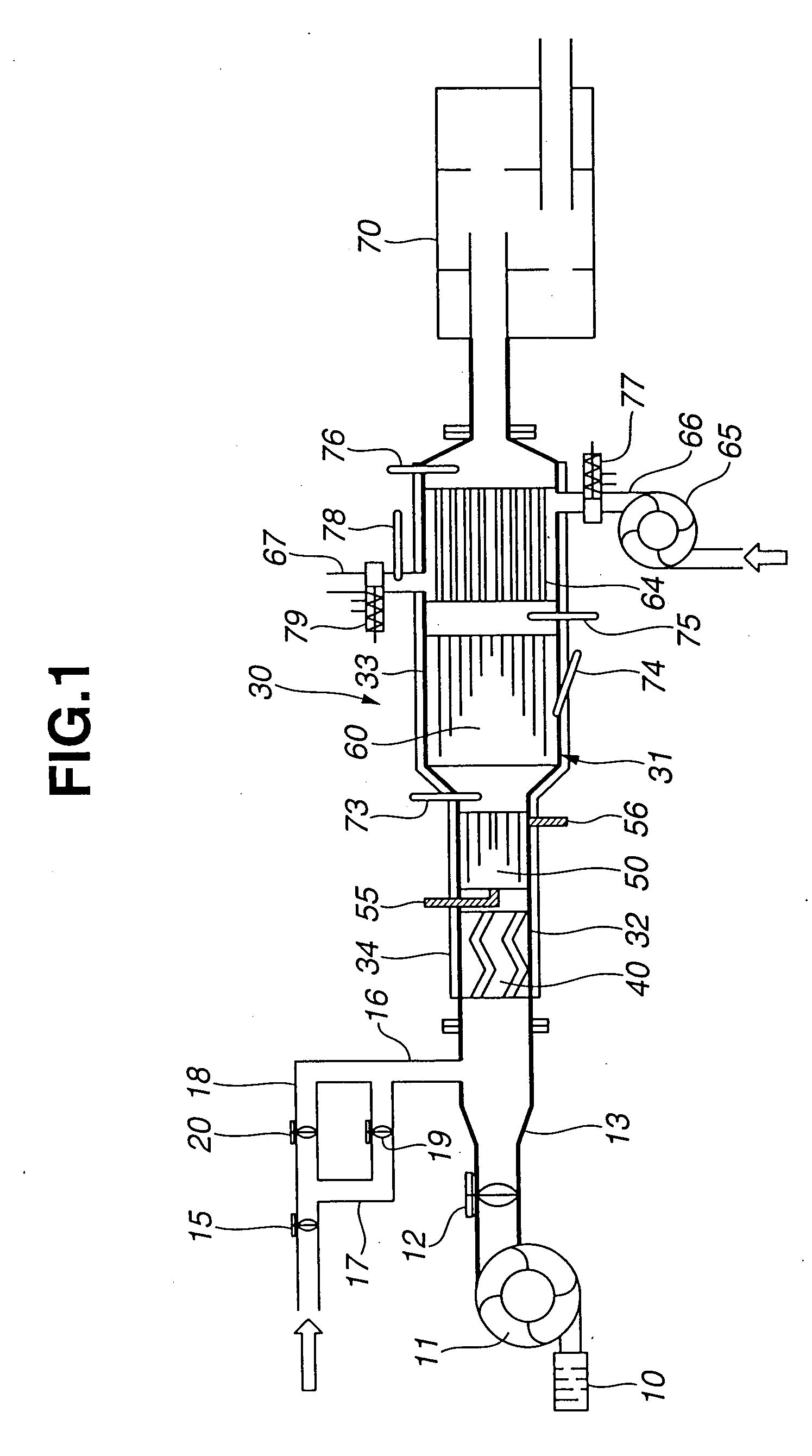

[0049]FIG. 1 shows a first hydrogen combustion heater according to a first preferred embodiment of the present invention. The first heater has a passage 13 for allowing hydrogen gas and air to flow therethrough. The passage 13 is formed at its upstream end with a blower 11. Air is sucked by the blower 11 into the passage 13 through a filter 10 and a flow rate regulating valve 12. The passage 13 (inner diameter: 58 mm) is formed on its sidewall with a hydrogen introducing pipe 16 (inner diameter: 8 mm), which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com