Compound polarization beam splitters

a polarization beam and beam splitter technology, applied in the field of optical assemblies, can solve the problems of reducing the contrast of the system, adding cost, and depolarizing the transmitted light caused, and achieve the effect of simple and less expensive construction, short back focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

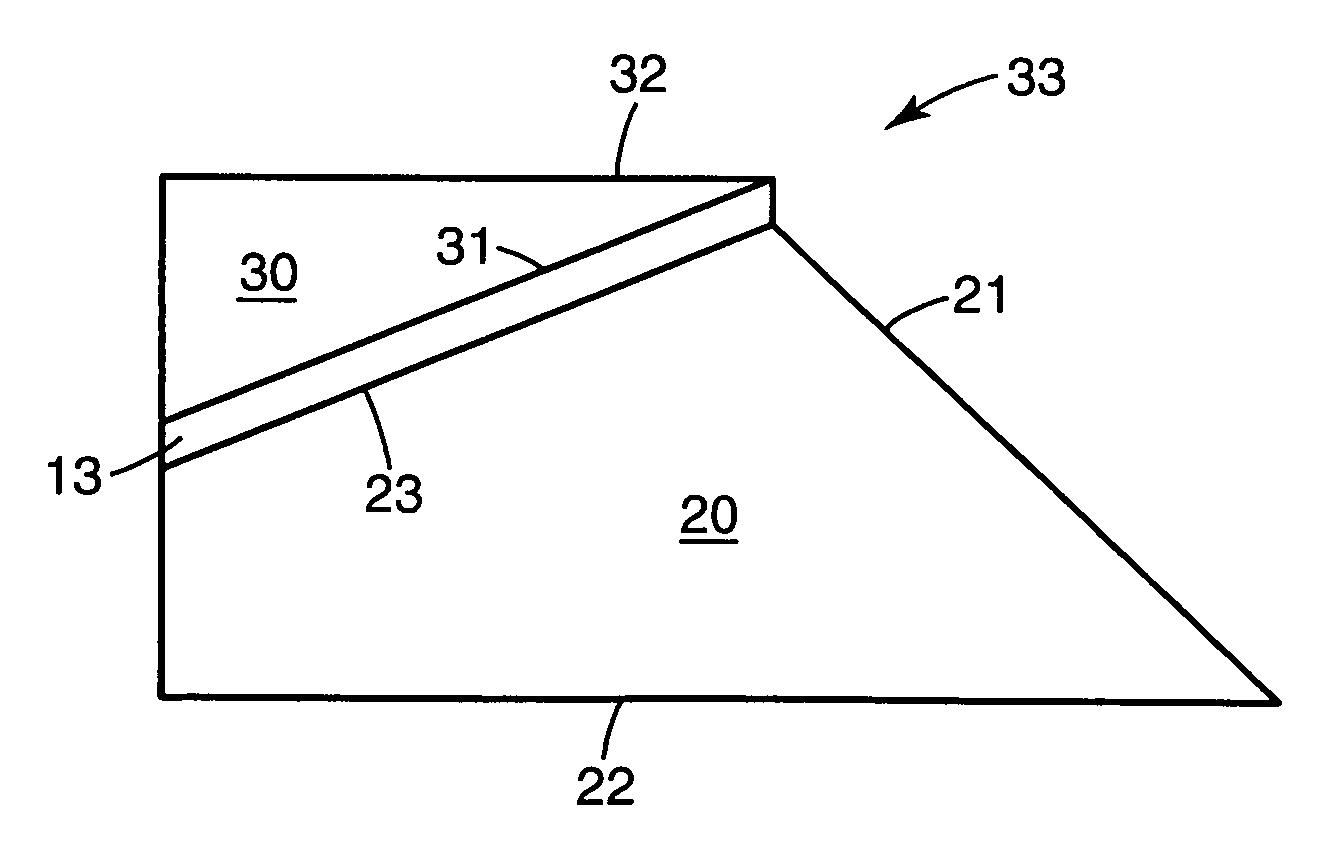

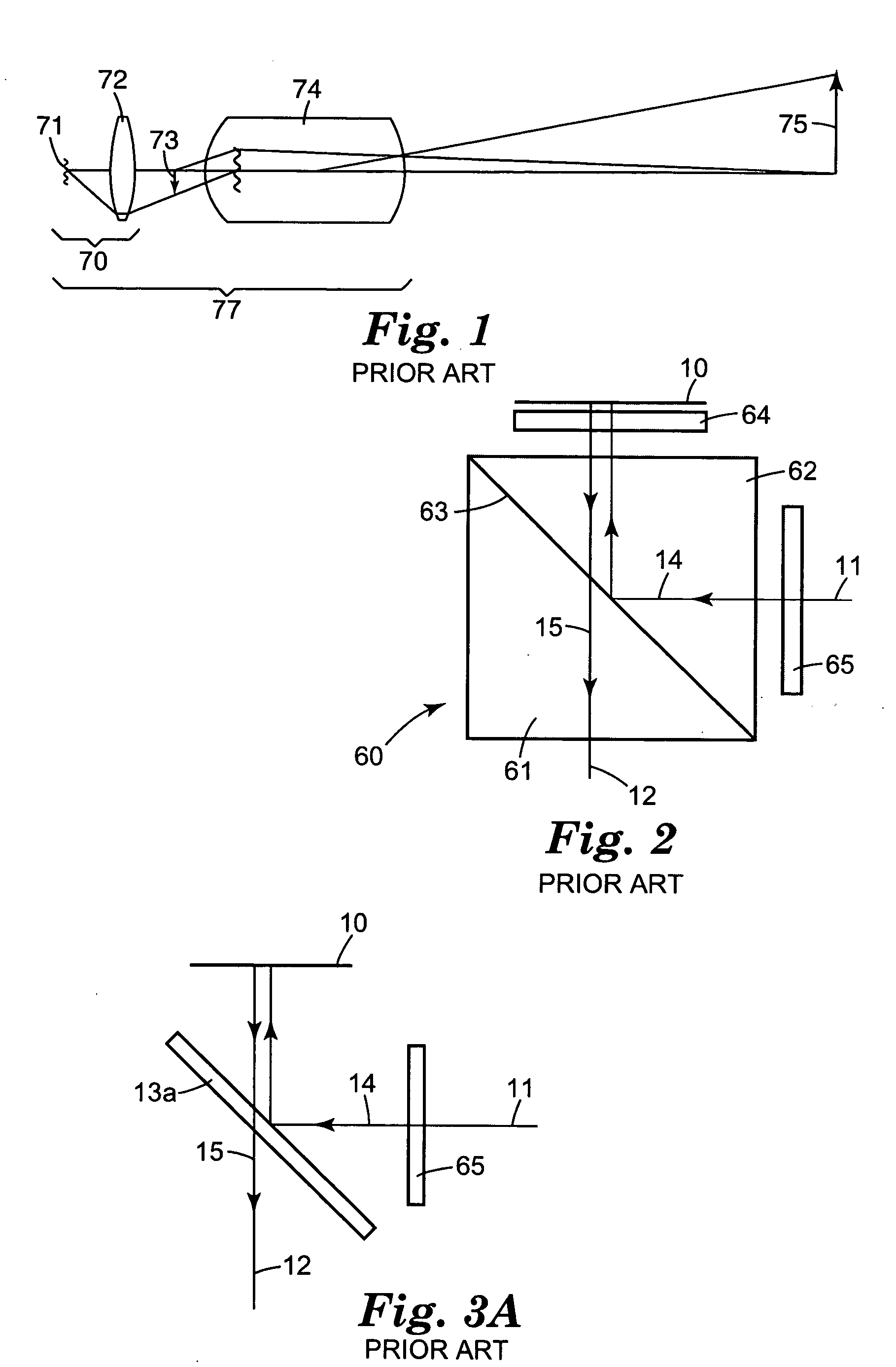

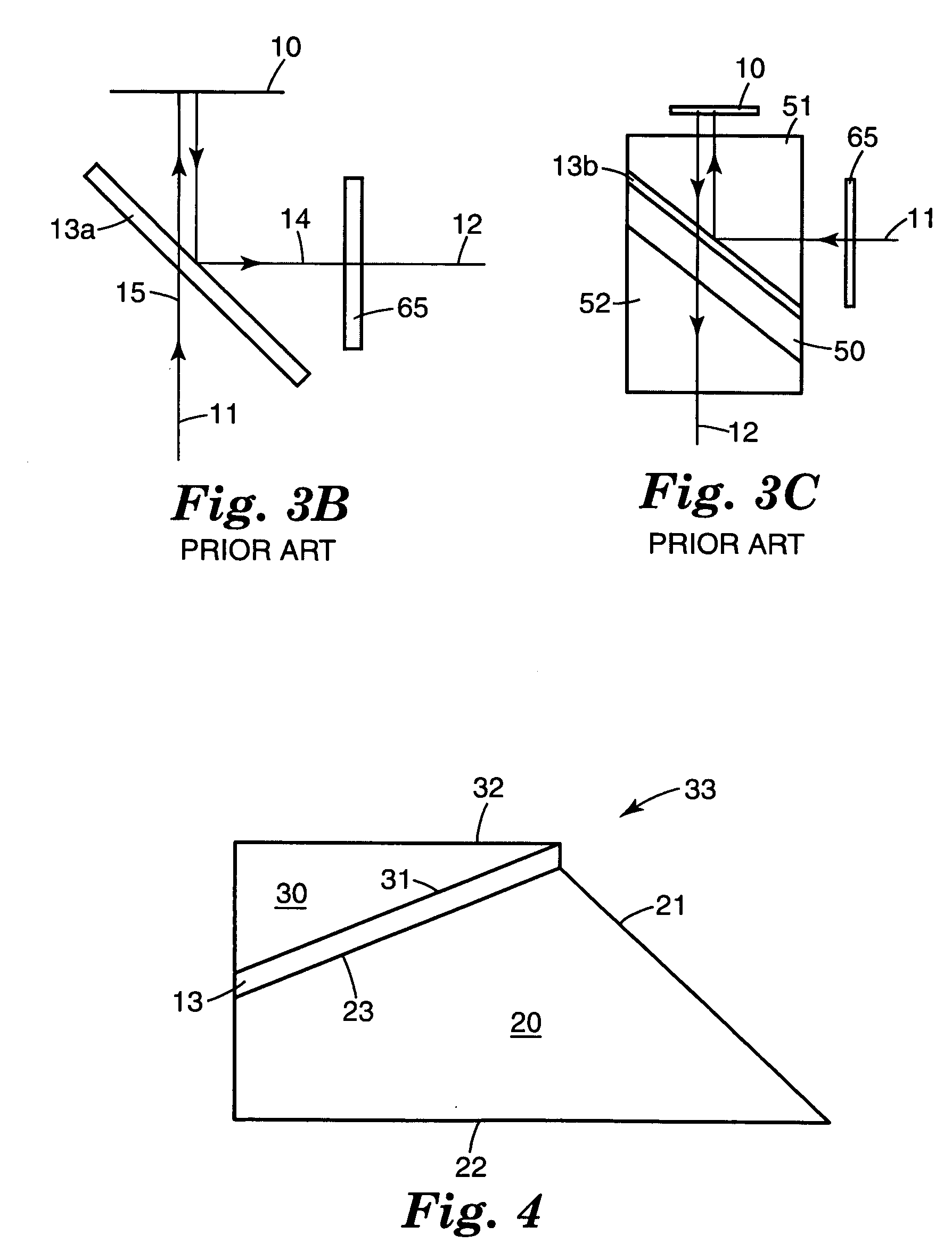

Embodiment Construction

[0099] As discussed above, the present invention relates to a prism assembly which utilizes the excellent polarization properties of Cartesian polarizers, including wire grid polarizers and multi-layer reflective polarizers, and can be used with, for example, a LCoS-based projection system with the following advantages: [0100] (1) no special requirements are imposed on the wire grid substrate, specifically, no thickness restrictions and no need for ultra-flatness; [0101] (2) complete environmental protection is provided for the wire grid structure; [0102] (3) there is no potential for deformation of the polarizer at elevated temperatures; [0103] (4) in the case of multi-layer reflective polarizers, the system has significantly reduced astigmatism thus reducing or eliminating the need for an astigmatism corrector; and [0104] (5) the imaging optical path inside of the prism assembly has reduced length compared to conventional PBSs.

[0105] In broadest terms, the invention is a compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com