Sputtering apparatus and sputter film deposition method

a sputtering apparatus and film deposition technology, applied in the direction of instruments, optical elements, vacuum evaporation coating, etc., can solve the problems of low productivity, significant productivity reduction, and difficult control of conventional film deposition apparatuses, and achieve high precision and rapid film deposition and film thickness control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Now, preferred embodiments of the sputtering apparatus and the sputter film deposition method according to the present invention will be described, referring to the accompanying drawings.

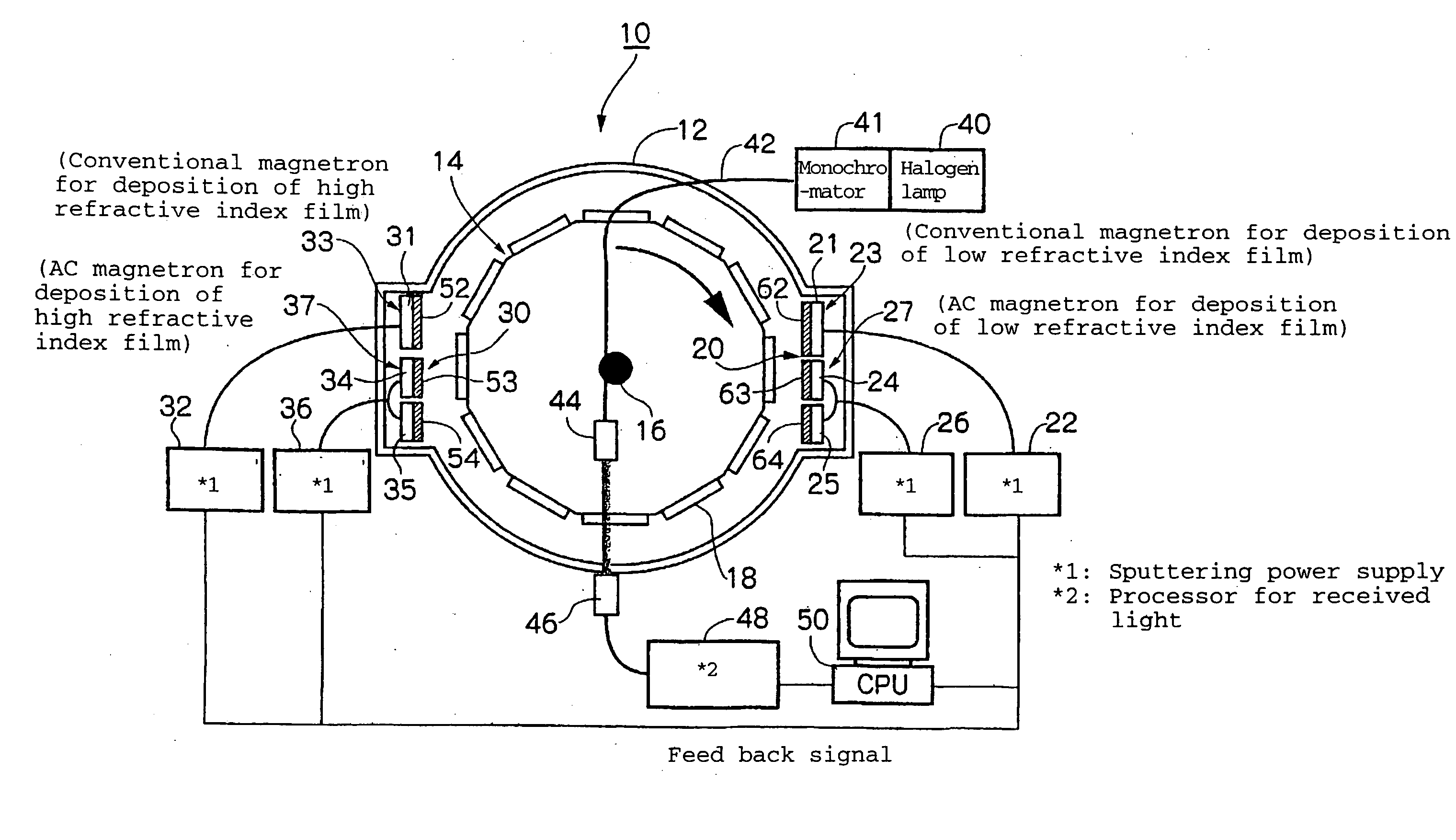

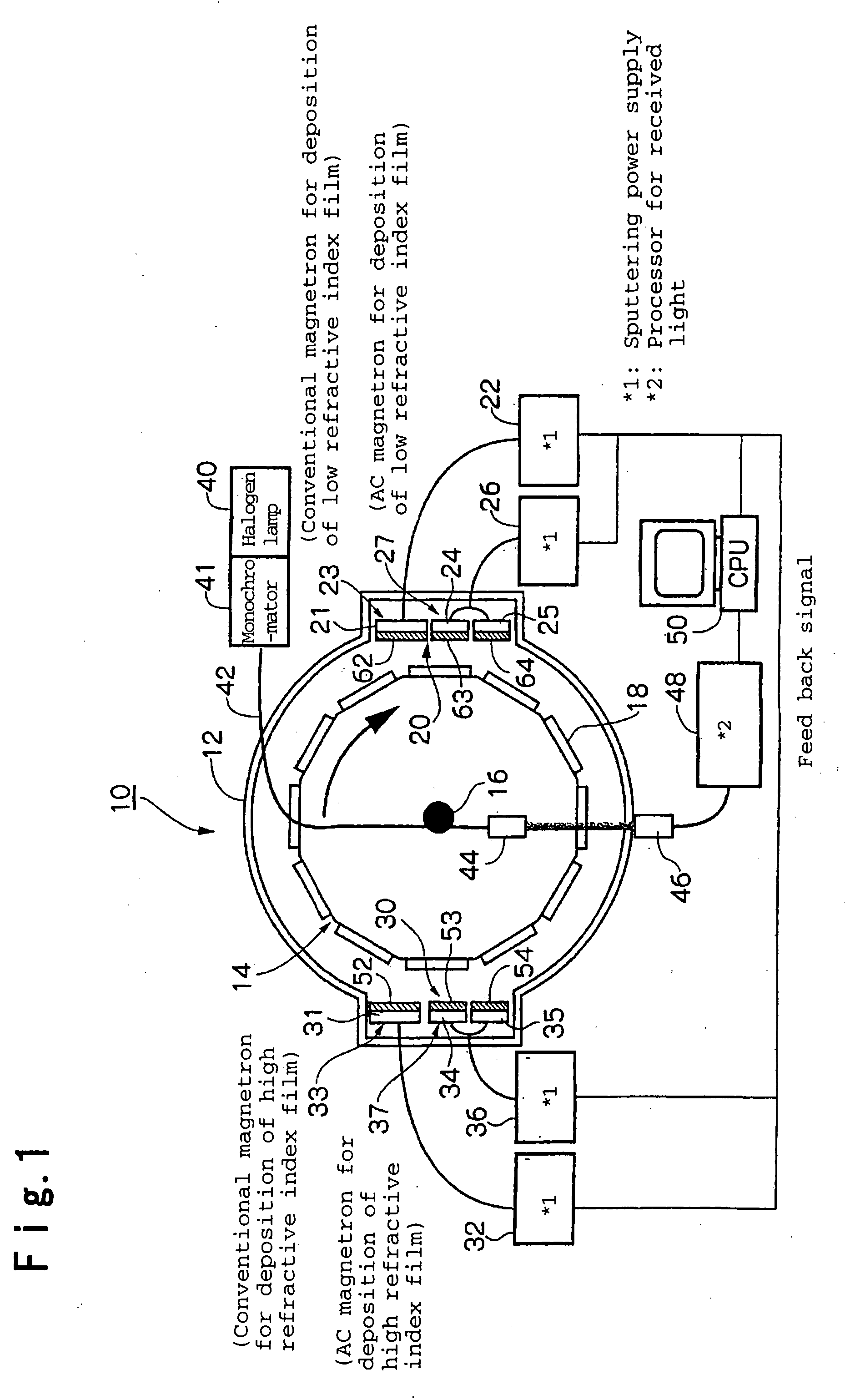

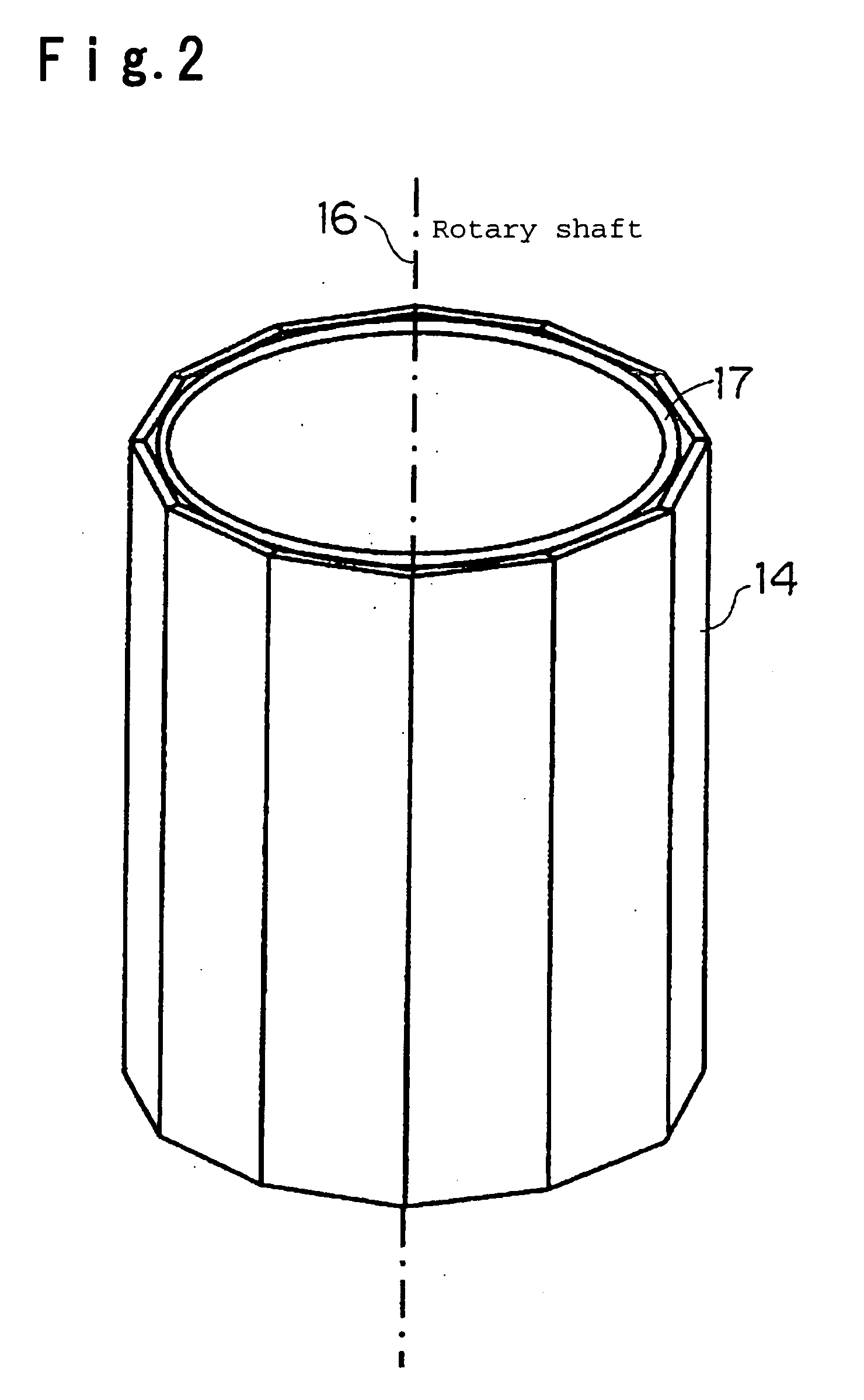

[0089]FIG. 1 is a schematic plan view showing the structure of the sputtering apparatus for depositing a multilayer optical film, according to an embodiment of the present invention, and FIG. 2 is a perspective view of substrate holders used in the apparatus. The sputtering apparatus 10 shown in FIG. 1 is a carousel type sputtering apparatus, which is configured to include a drum (not shown in FIG. 1 and indicated by reference numeral 17 in FIG. 2) and the substrate holders 14 provided on an outer peripheral surface of the drum 17 in a cylindrical chamber 12 having a height of 1.5 m and a diameter of 1.5 m, wherein the substrate holders 14 are combined in a regular dodecagonal shape having a diameter of 1 m and are supported so as to be rotatable about a central shaft 16 as the center of rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| incident angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com