Apparatus and method for penetrating oilbearing sandy formations, reducing skin damage and reducing hydrocarbon viscosity

a technology of oilbearing sandy formations and apparatus, applied in the direction of explosive charges, weapons, projectiles, etc., can solve the problem of high energy consumption, and achieve the effect of ensuring aluminum hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

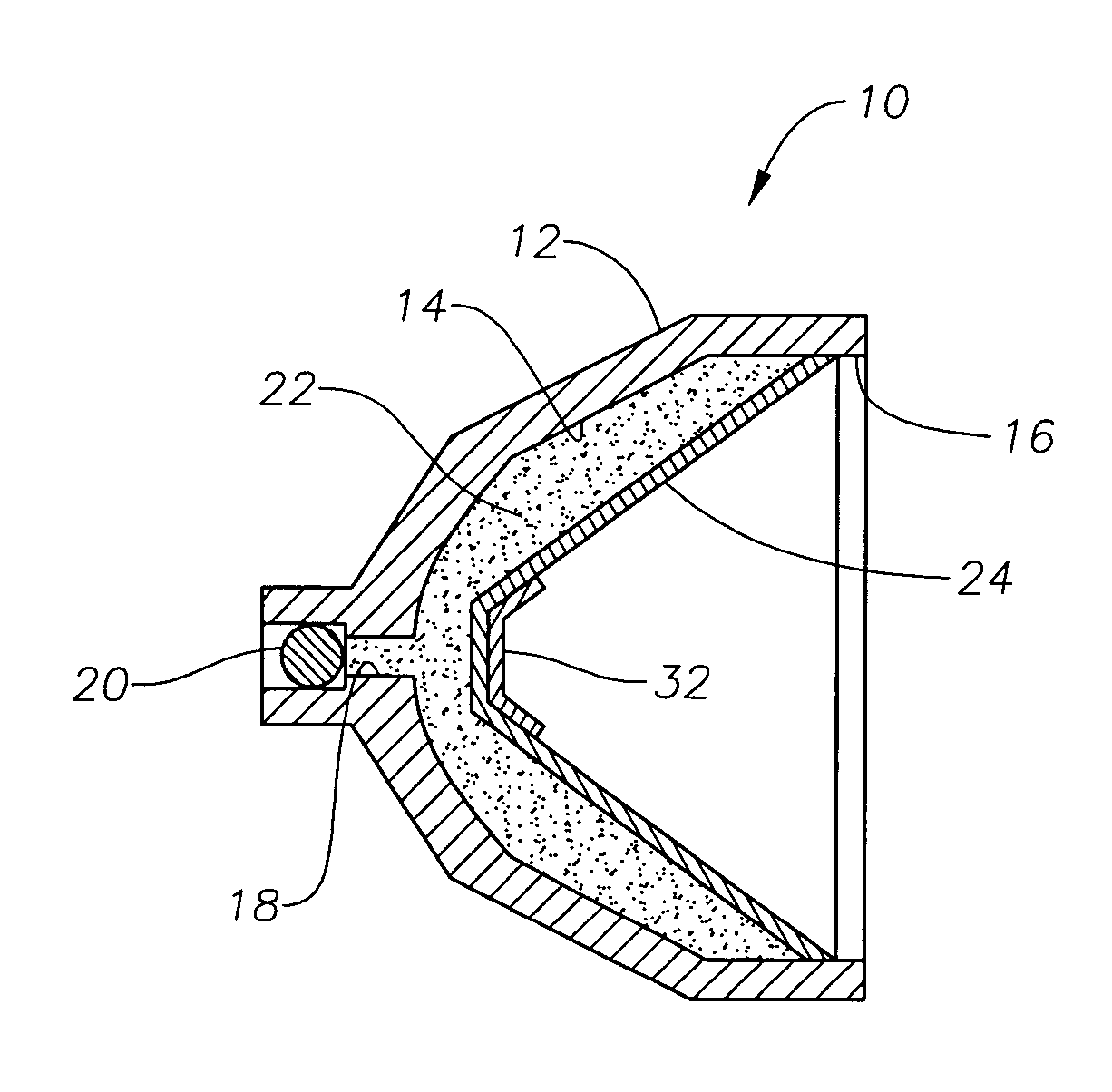

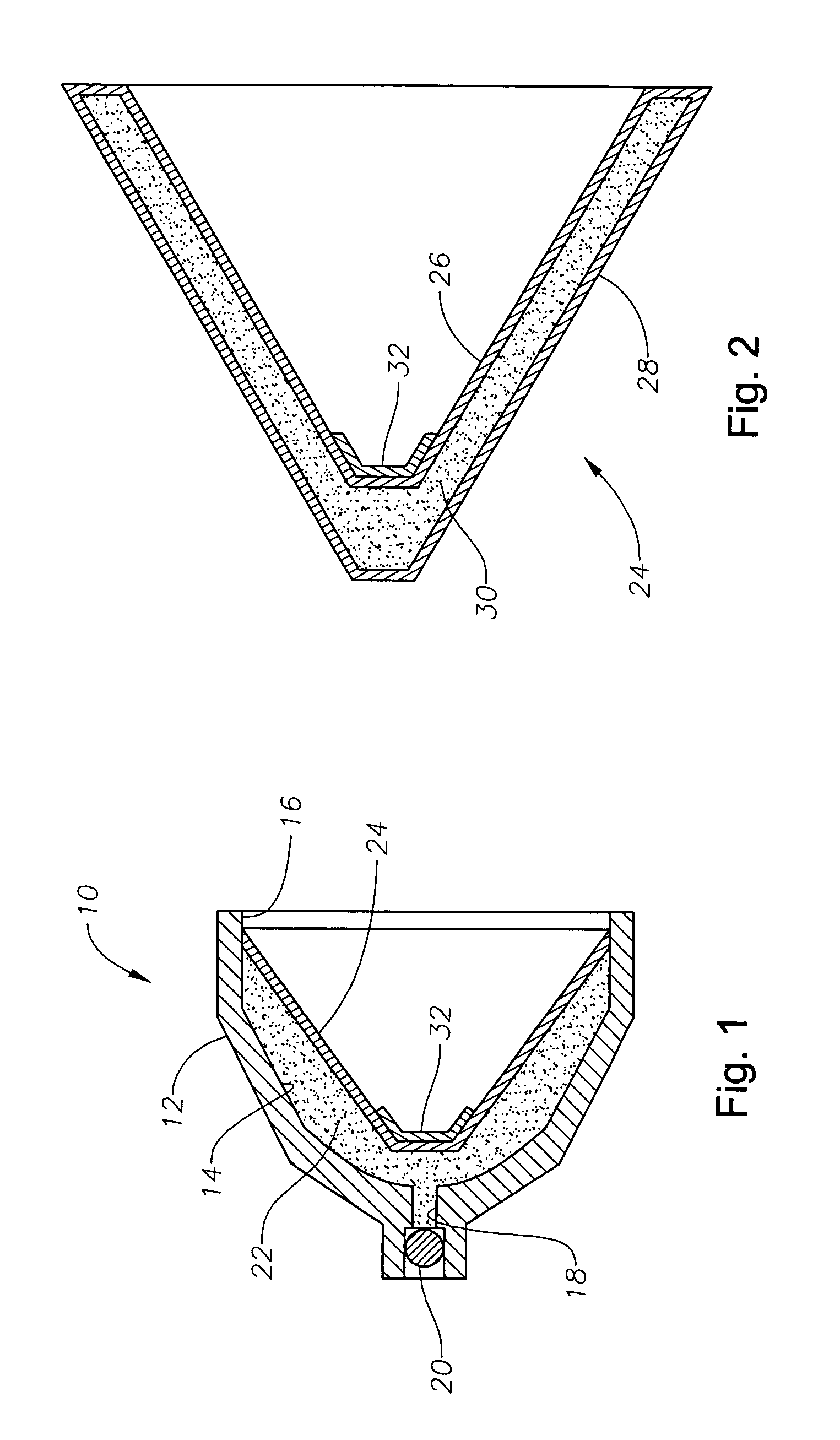

[0021]FIG. 1 illustrates an exemplary shaped charge 10 that is constructed in accordance with the present invention. The shaped charge 10 includes an outer charge casing, or case, 12 that is typically fashioned of metal. The casing 12 defines a charge cavity 14 that is generally hemispherical and presents an open forward end 16. At the rear end of the casing 12, a small aperture 18 is disposed. A small amount of booster is usually placed in the aperture 18. A detonator 20 is retained adjacent to the aperture 18. The detonator 20 typically comprises a detonation cord, or other items known in the art for initiation of a shaped charge. An explosive charge 22 is disposed within the charge cavity 14 and within the forward portion of the aperture 18 so as to be in contact with the booster which is, in turn, in contact with or in close proximity with the detonator 20. The explosive material may comprise RDX (Hexogen, Cyclotrimethylenetrinitramine), HMX (Octogen, Cyclotetramethylenetetranit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com