Polishing product element, particularly for finishing optical lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

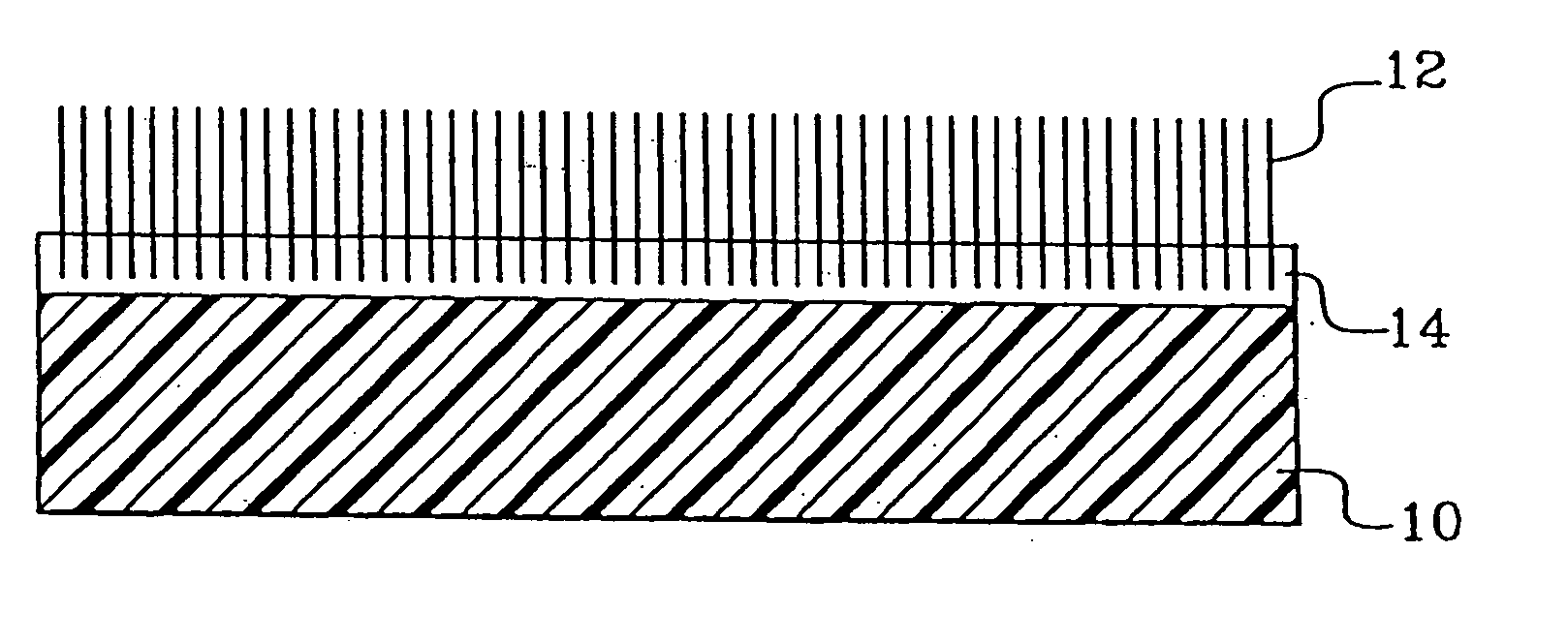

Image

Examples

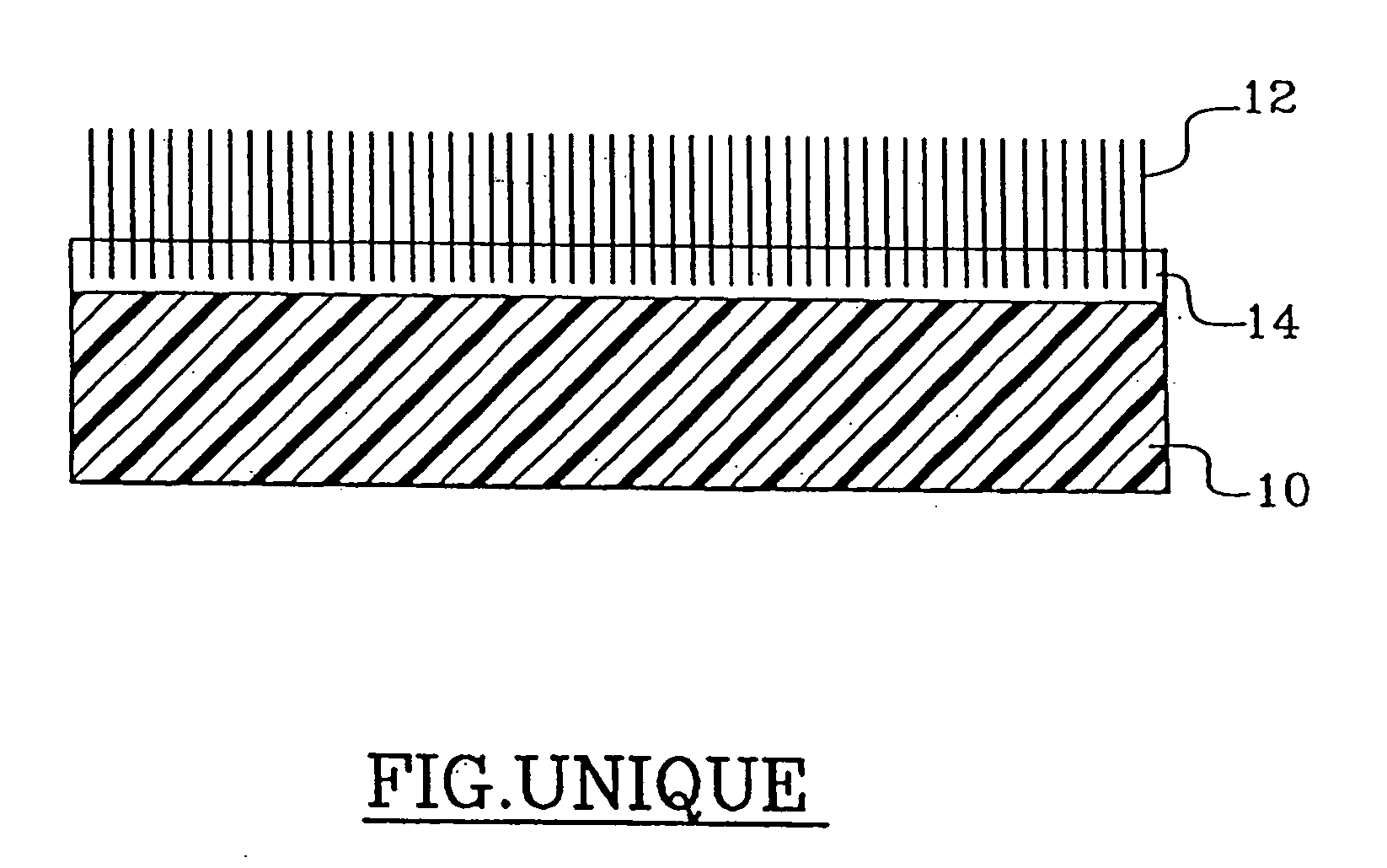

second embodiment

[0034] Whereas the pad with a cotton fabric base plate is used with a tool made of a rigid support coated with an elastic foam on which the pad is affixed using an adhesive in the usual manner, the pad according to this second embodiment is used on a tool without an elastic coating and is affixed directly onto the hard and smooth surface of the aforesaid tool via the adhesive.

[0035] This embodiment makes it possible to substantially improve the longevity of the pad and to thus further increase the ability of the same pad to polish additional surfaces.

first embodiment

[0036] In fact, in the first embodiment described above, the pad is able to polish about twenty surfaces, after which it is discarded. But this discarding is not a consequence of too many fibers having been pulled off, it simply due to the detachment of the pad from the tool because of the degradation of its adhesive connection with the tool because of moisture coming from the polishing liquid.

[0037] In the case of the pad according to the second embodiment, the connection with the tool is much more durable because of the polyurethane foam base plate 10, which constitutes a barrier between the polishing liquid and the adhesive that is interposed between the pad and the tool and which makes it possible to benefit from the excellent anchorage of the fibers 12 imparted by the polyurethane based adhesive 14 for a much longer time, i.e., to polish a much greater number of surfaces with the same pad before the latter detaches from the tool, this detachment being inevitable, but being reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com