Folded tube for a heat exchanger and method of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

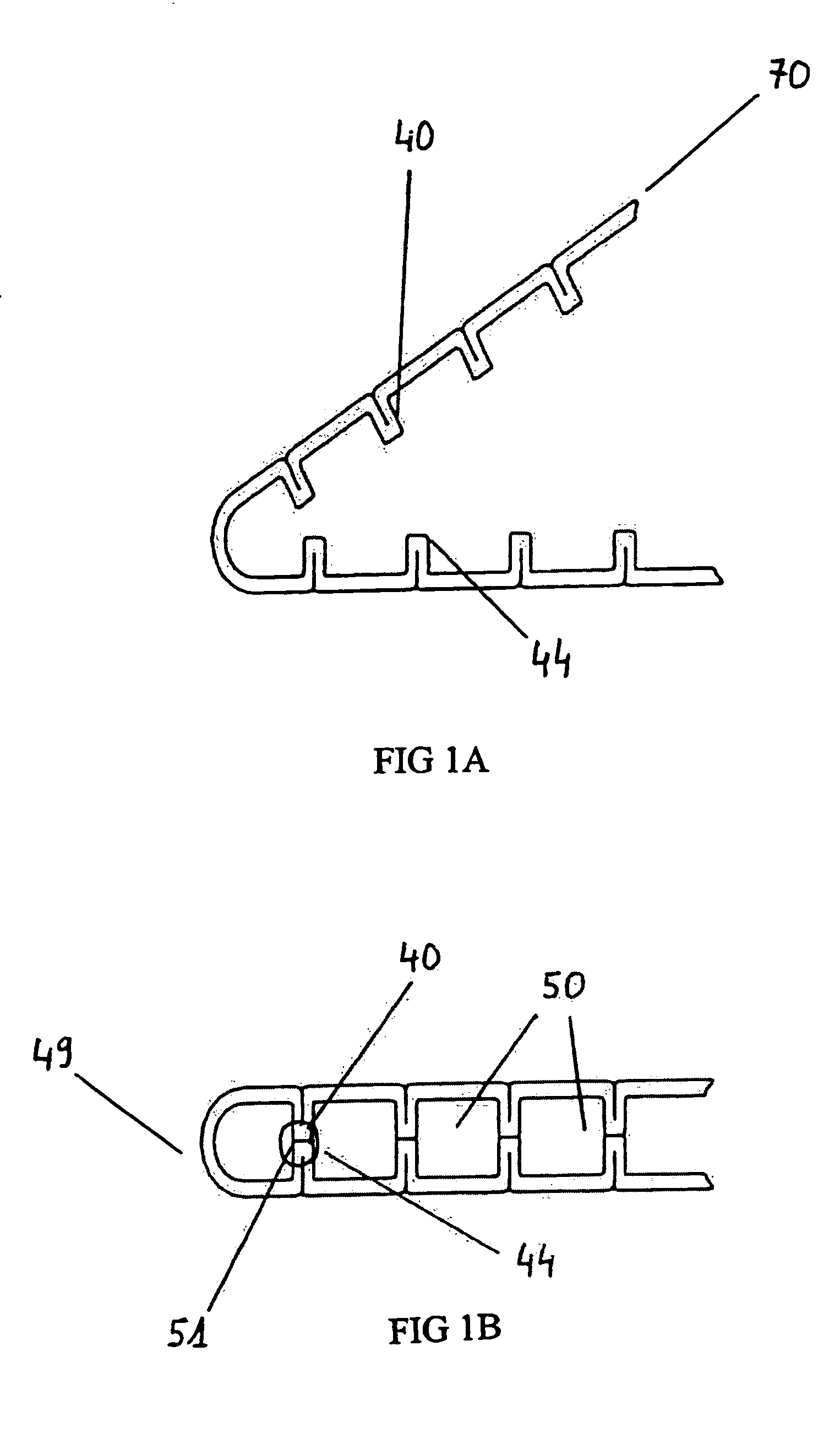

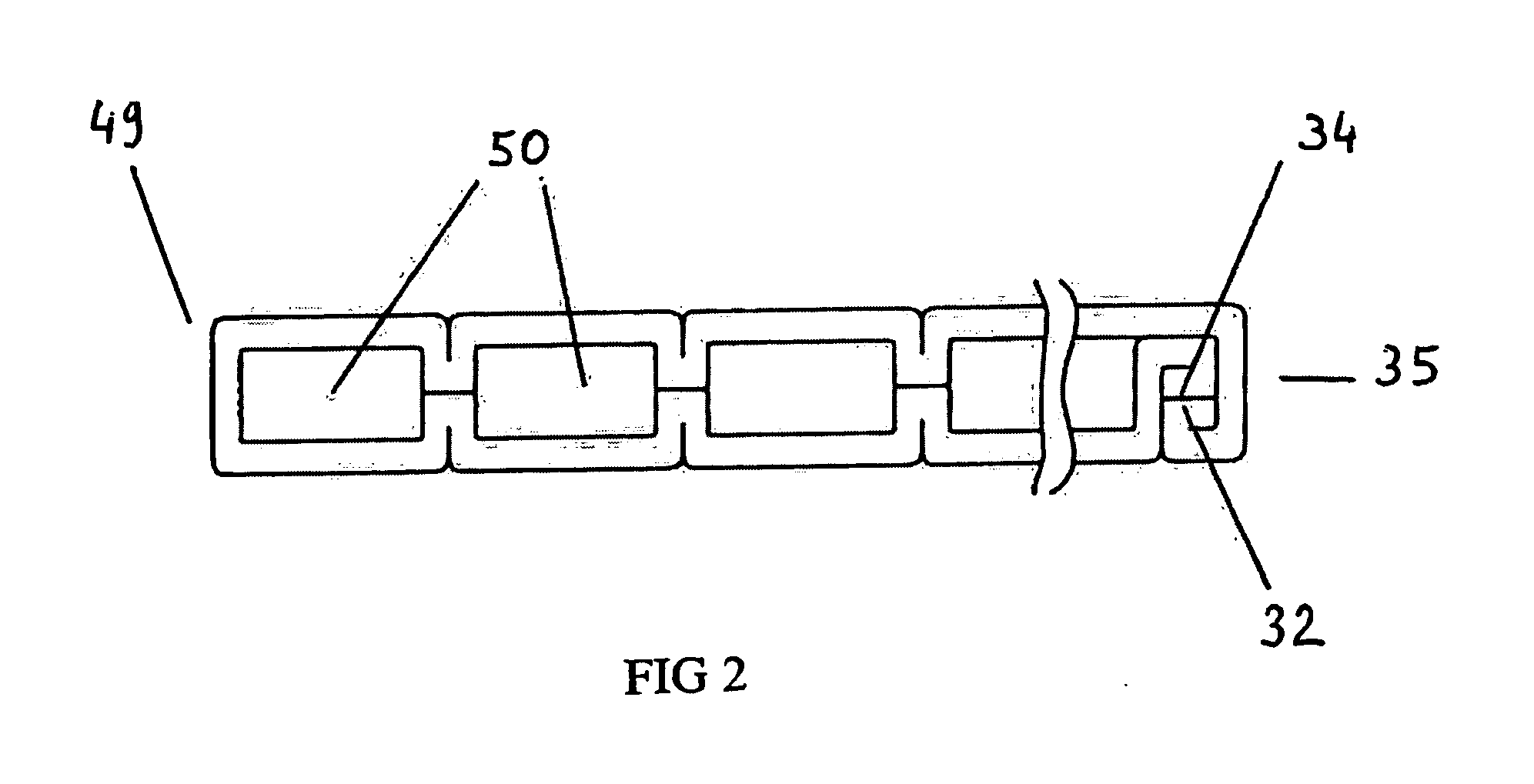

[0032] Referring to the drawings and particularly to FIG. 1a, 1b and FIG. 2 the basic process of tube folding in accordance with the present invention, and an embodiment of the subsequent tube 49 of the present invention is illustrated. A sheet material 70 is folded progressively into a muli-port 50 tube. The sheet 70 is folded to form several half-webs or internal half webs 40, 44, then bent into tube form. FIG. 1b shows the half web from the top surface 40 and the half webs from the base surface 44 face-to-face and abutting one another at point 51, together forming webs separating multi-ports.

[0033] Referring to FIG. 2, at one end of the sheet ends 34 and 32, are bent twice inwardly on one end 34 yielding three layers and bent once on end 32 yielding 2 layers, together forming a 5-layer locked tube end 35, yielding specific relations between tube height and sheet gauge.

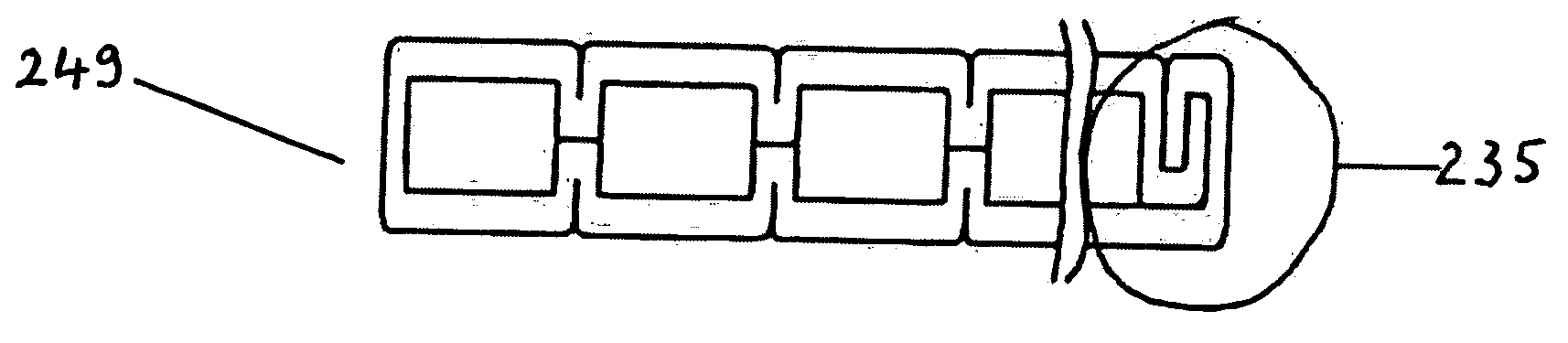

[0034] Referring to FIGS. 3a and 3b, the tube locking features 135,235 are formed. In FIG. 3a, one end 132 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com