Cooking oven with a cooled door that permits pyrolysis

a technology of pyrolysis and oven door, which is applied in the field of cooking oven, can solve the problems of obtaining the cooling of the outer pane at the expense of the effective cleaning of the inner pane, and achieve the effects of avoiding turbulence, enhancing the cooling of the outer pane, and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

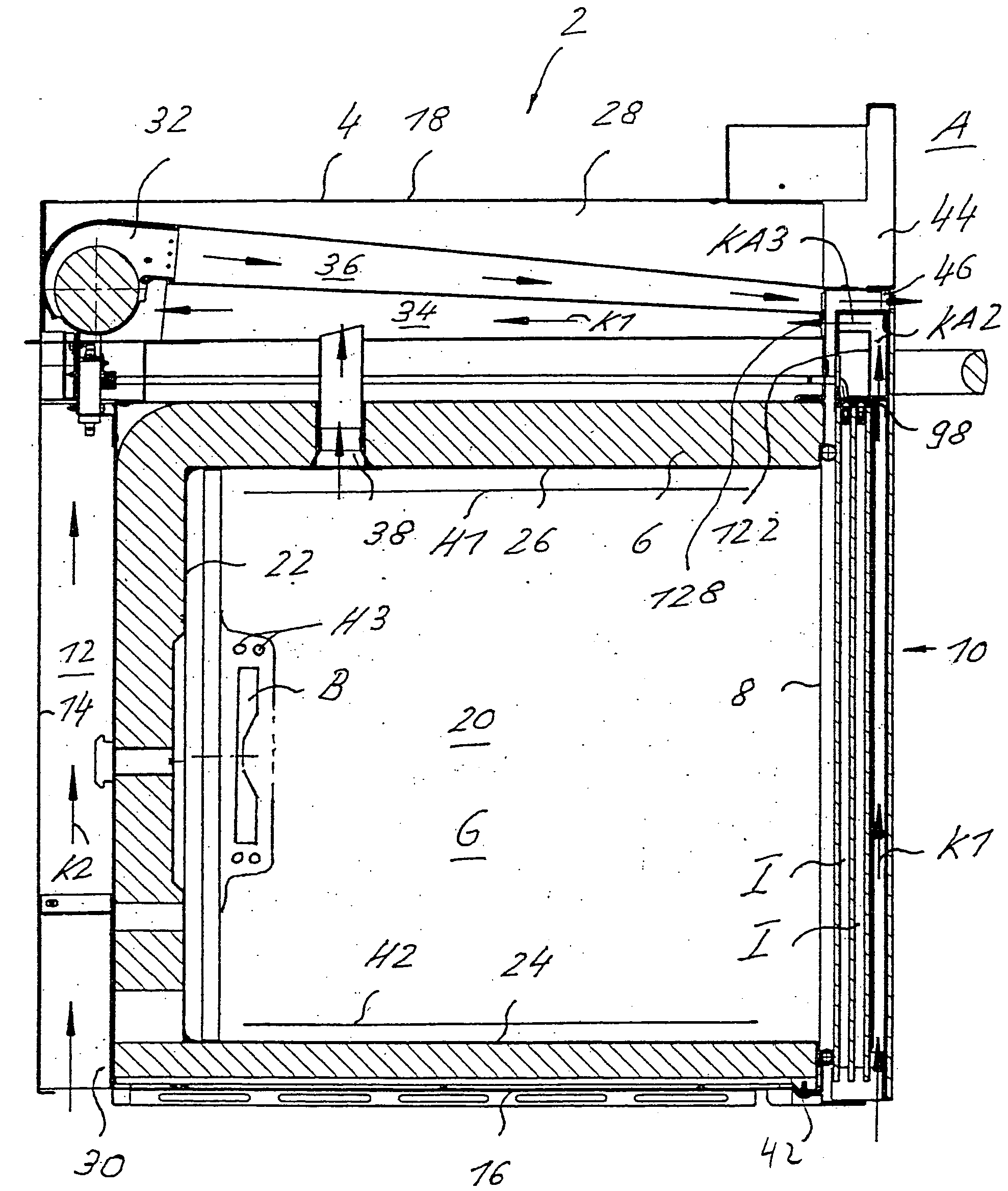

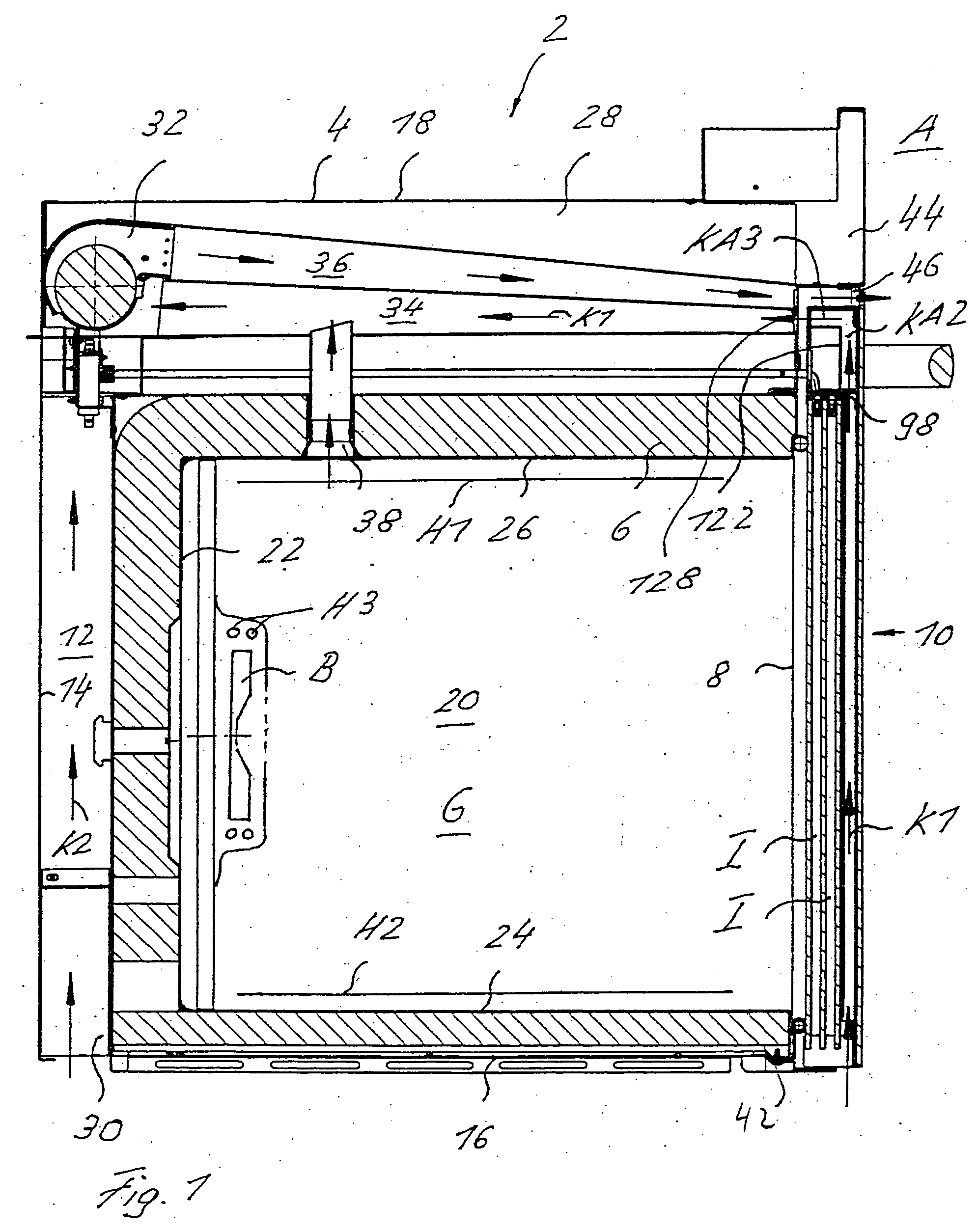

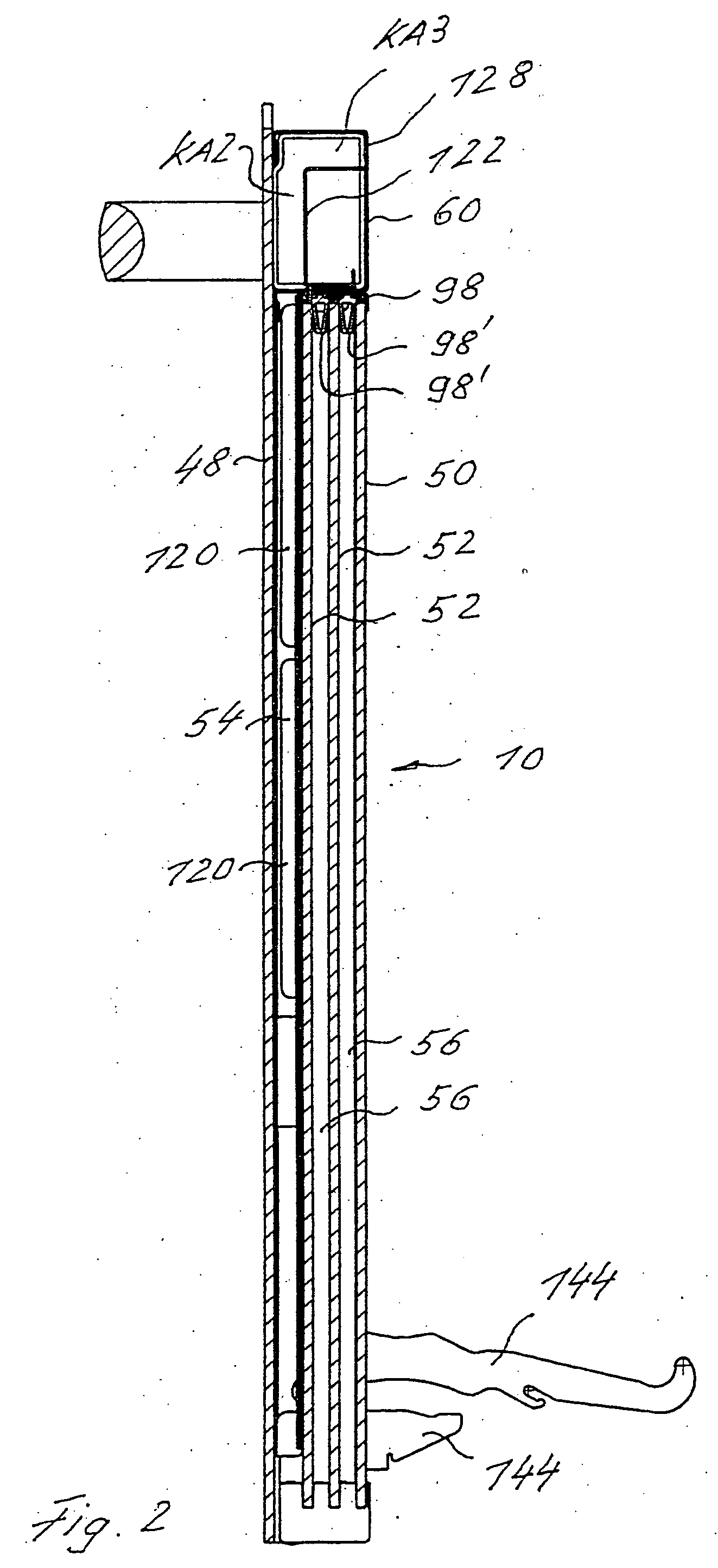

[0026] An example of an oven 2 that incorporates the present invention is shown in FIG. 1. The oven 2 includes a housing 4 that contains a heatable oven chamber 6 and a loading port 8 that can be closed by means of a door 10.

[0027] The housing 4 is a generally a cubic structure with an open front, and the oven chamber 6 has a generally cubic shape. The housing 4 has two mutually opposite side panels 12 (only one shown), a rear panel 14, a bottom panel 16 and a top panel 18. The oven chamber 6 has two mutually opposite side walls 20 (only one shown), a back wall 22, a bottom plate 24 and a top plate 26. Extending between the top panel 18 of the housing 4 and the top plate 26 of the oven chamber 6 is a horizontally extending clearance space 28. A vertical channel 30 is located between the rear panel 14 of the housing 4 and the back wall 22 of the oven chamber 6. The vertical channel 30 opens toward the bottom. A blower 32 is located in the area of the junction of the clearance space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com