Spark generating apparatus having strain gage cylinder pressure measurement feature

a technology of pressure measurement and spark generating apparatus, which is applied in the direction of work measurement, measurement devices, instruments, etc., can solve the problems of large and costly production of coils and/or spark plugs, increase cost, and increase the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

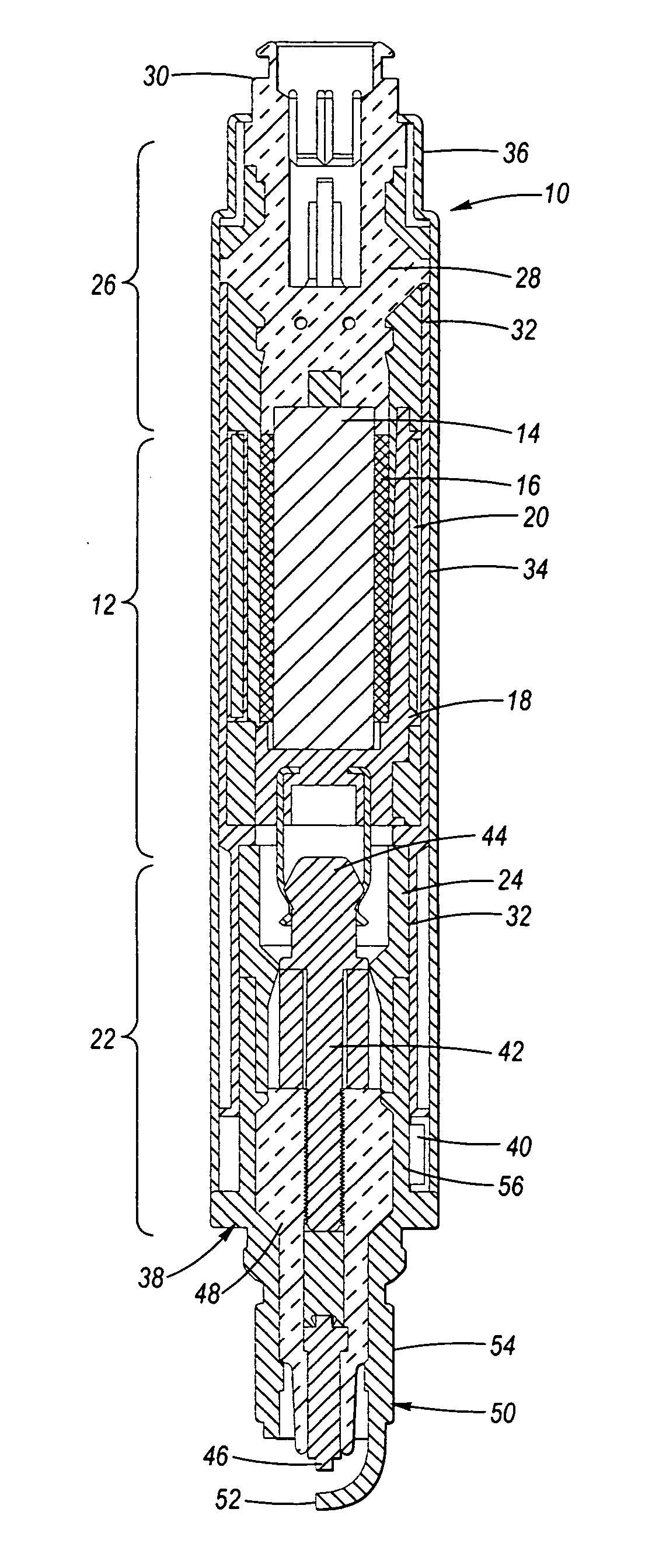

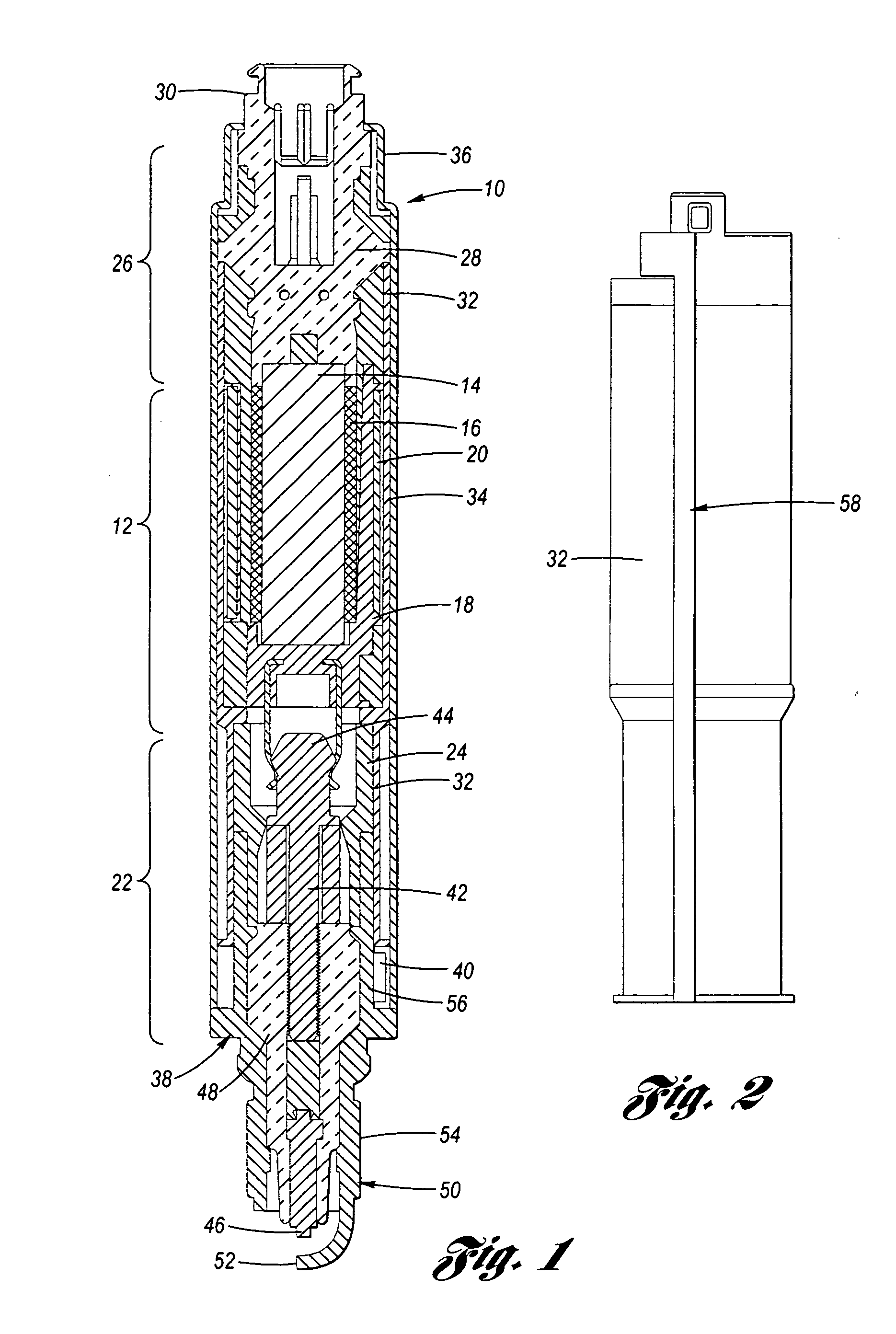

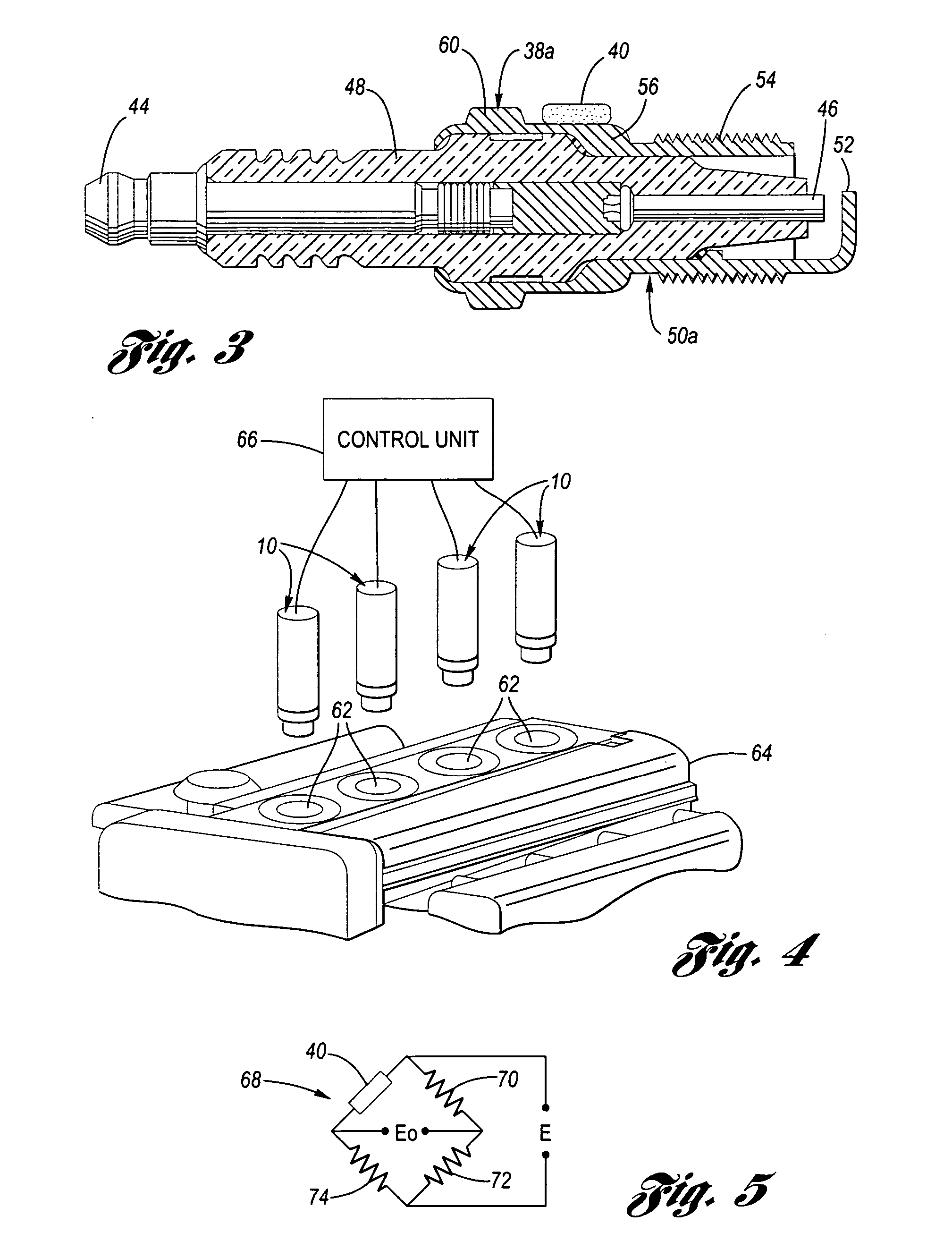

[0017] Referring now to the drawings wherein like reference numerals are used to identify identical components in the various views, FIG. 1 shows a preferred embodiment of an integrated ignition coil, spark plug and pressure sensor assembly 10 in accordance with the present invention. The assembly 10 is adapted for installation to a conventional internal combustion engine 64 through a spark plug shell and in threaded engagement with a spark plug opening 62 into a combustion cylinder. This arrangement is best shown in FIG. 4.

[0018]FIG. 1 illustrates assembly 10 having a transformer portion 12 comprising a core 14, a primary coil 16, a secondary spool 18 and a secondary coil 20, a connection portion 22 comprising a high-voltage boot 24, a control circuit portion 26 comprising an assembled connector portion 28 and a circuit interface portion 30, a coil case 32, an outer housing or shield 34 comprising a fastening head 36, a spark plug assembly 38, and a pressure sensor assembly compri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com