Surface vessel with submersible passenger compartment

a technology for submersible vessels and passenger compartments, applied in vessel construction, underwater equipment, floating buildings, etc., can solve the problems of limiting the stability of the surface vessel and the inability to afford the same viewing experience as the submarin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

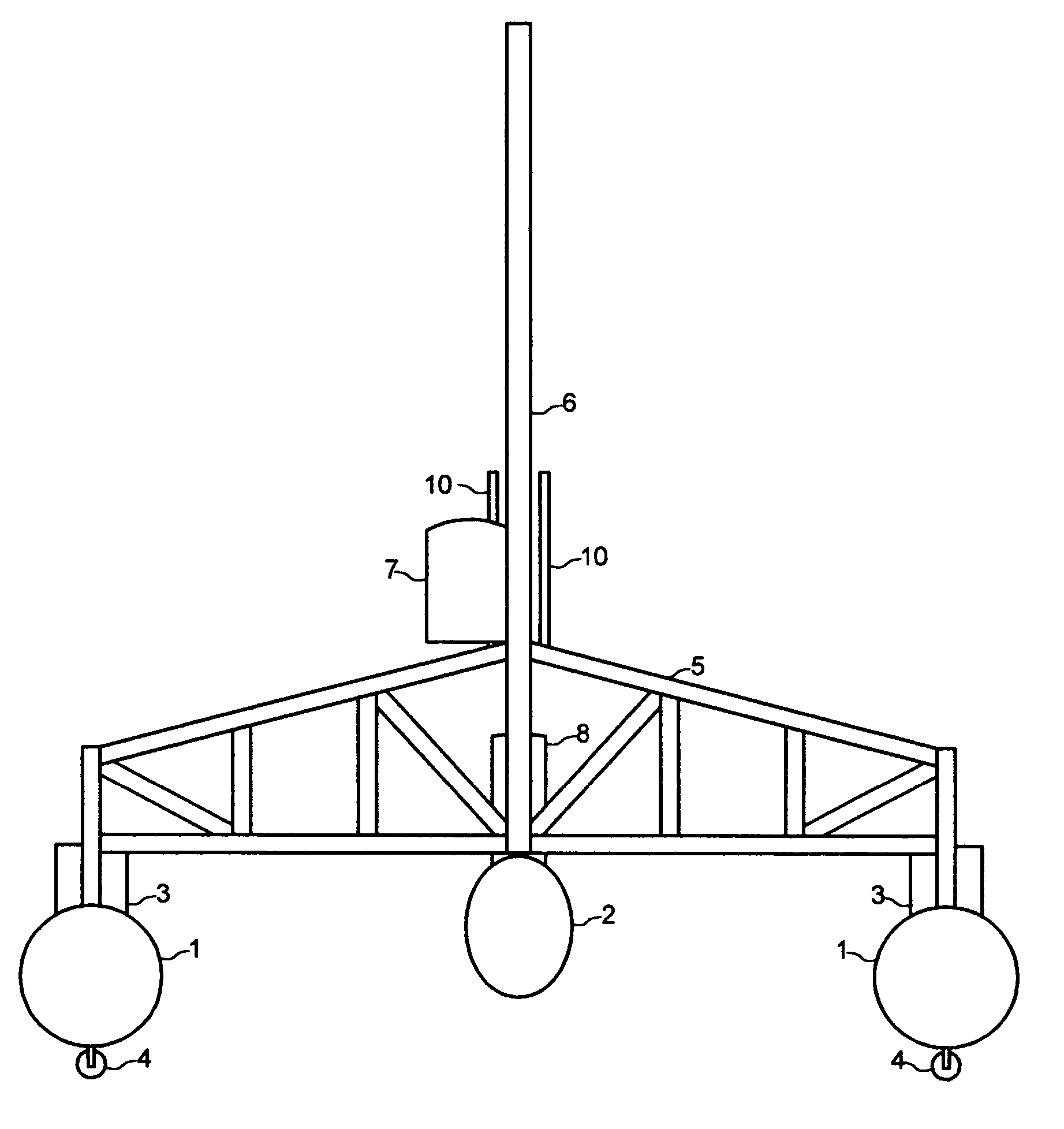

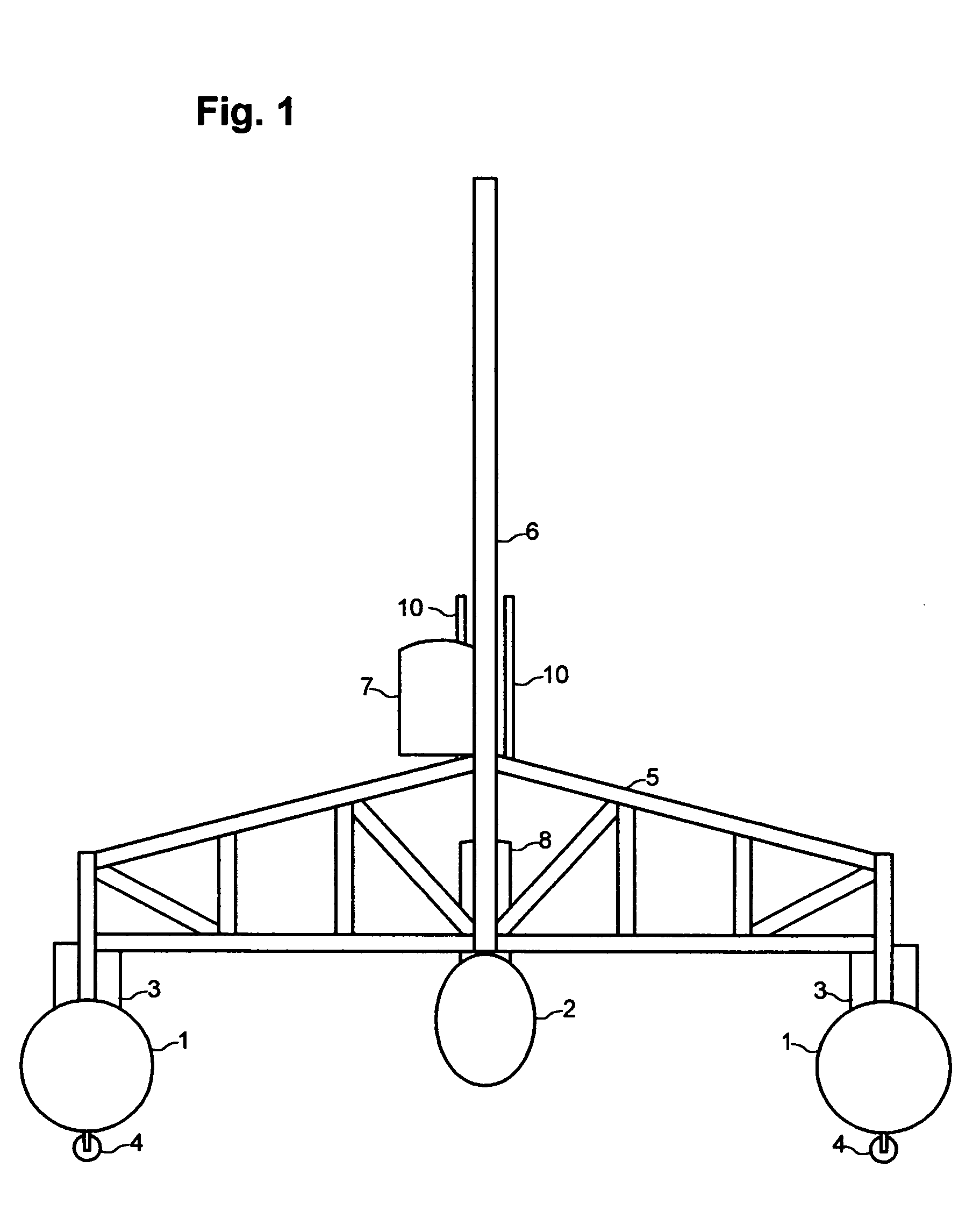

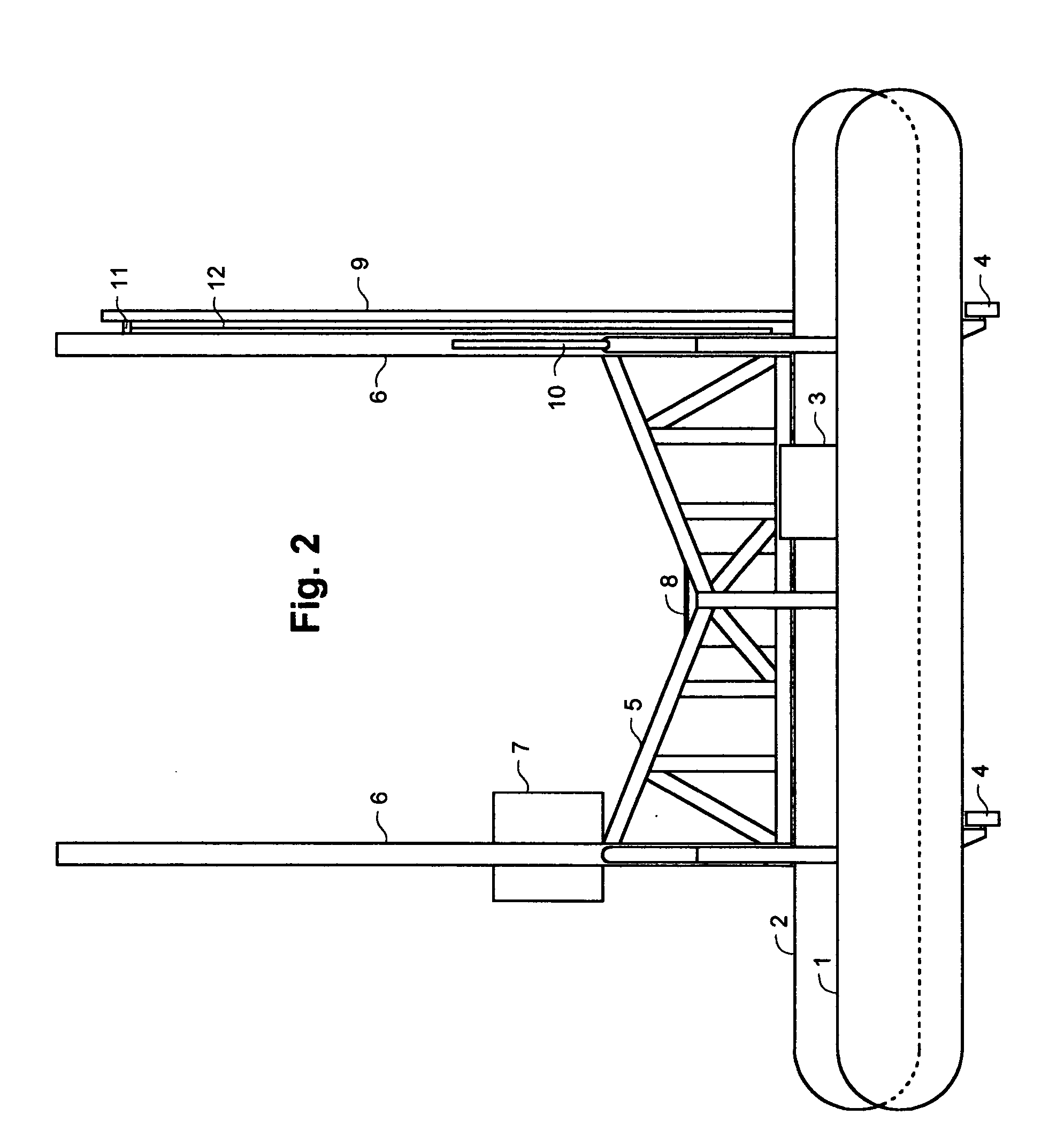

[0021] In the embodiment shown, and with reference to FIG. 1 through FIG. 6, this semi-submersible vessel consists of two outer hulls 1 connected to a framework 5 thereby forming a catamaran type structure. Hydraulic cylinders 6 are integrated vertically into the framework 5. The piston rods 13, of said main hydraulic cylinders 6, protrude below the framework 5 and connect rigidly to the passenger hull 2. The outer hulls are vertically divided into separate compartments; each compartment is horizontally divided by plates 23 into two separate sections. The upper section, of each compartment, forms a sealed air tank 25. The lower section, of each compartment, forms a water ballast tank 26. Each water ballast tank 26 is equipped with a vent pipe 24 connecting the top of the tank to the outside atmosphere. The bottom of the water ballast tank 26 is equipped with a water valve 21 said valve being formed and positioned in such a way that it is flush with the outer surface of the hull 1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com