Gas supplying mechanism in a gas powered toy gun

a gas-powered toy gun and gas-supplying technology, which is applied in the direction of compressed gas guns, white arms/cold weapons, weapons, etc., can solve the problem that the position of the hammer b>14/b>, which is not stable enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0027]FIG. 3 shows an example of a gas powered toy gun to which gas supplying mechanism in a gas powered toy gun according to the present invention is applied.

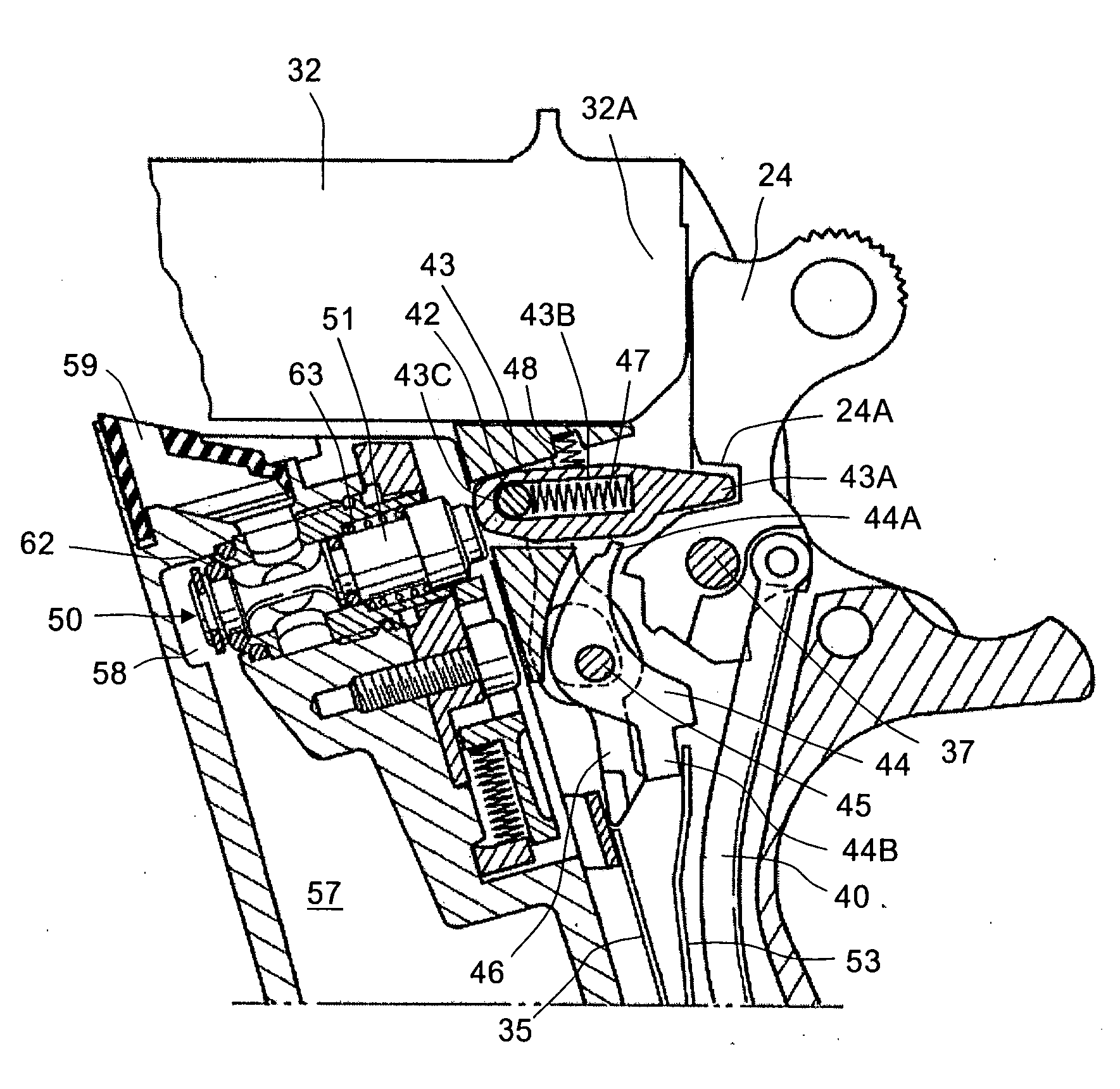

[0028] Referring to FIG. 3, the gas powered toy gun to which the first embodiment of gas supplying mechanism according to the present invention is applied has a body 30 in which a trigger 21, a barrel 22, a bullet holding chamber 23 positioned in a rear portion of the barrel 22, a hammer 24 and a grip 25 are provided, a case 31 held to be detachable in the grip 25, and a slider 32 provided to be movable along the barrel 22. The bullet holding chamber 23 is formed in a tubular member 23A which is made of elastic frictional material, such as rubber, and put in the inside of the rear portion of the barrel 22.

[0029] In the grip 25, a movable bar member 33 extending backward from the trigger 21 is provided to be movable in the direction along the barrel 22. When triggering, the trigger 21 is moved backward from an operational init...

second embodiment

[0065]FIG. 10 shows an example of a gas powered toy gun to which gas supplying mechanism in a gas powered toy gun according to the present invention is applied.

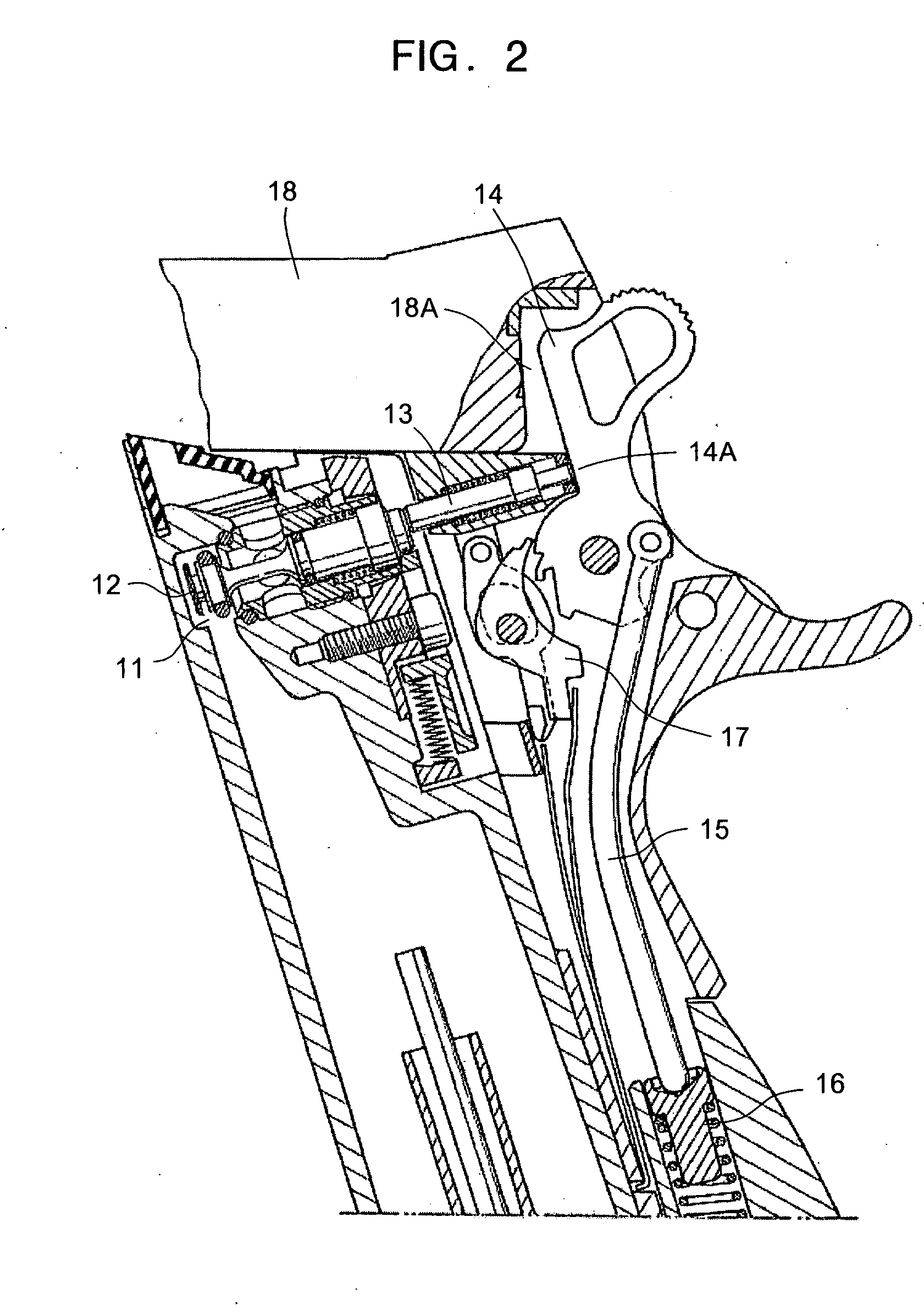

[0066] Referring to FIG. 10, the gas powered toy gun to which the second embodiment of gas supplying mechanism according to the present invention is applied has a body 80 in which a trigger 71, a barrel 72, a bullet holding chamber 73 positioned in a rear portion of the barrel 72, a hammer 74 and a grip 75 are provided, a case 81 held to be detachable in the grip 75, and a slider 82 provided to be movable along the barrel 72. The bullet holding chamber 73 is formed in a tubular member 73A which is made of elastic frictional material, such as rubber, and put in the inside of the rear portion of the barrel 72.

[0067] In the grip 75, a movable bar member 83 extending backward from the trigger 71 is provided to be movable in the direction along the barrel 72. The trigger 71 is attached with an axis 84 to the body 80. When trigger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com