Pourer with improved locking and cap equipped with same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example embodiments

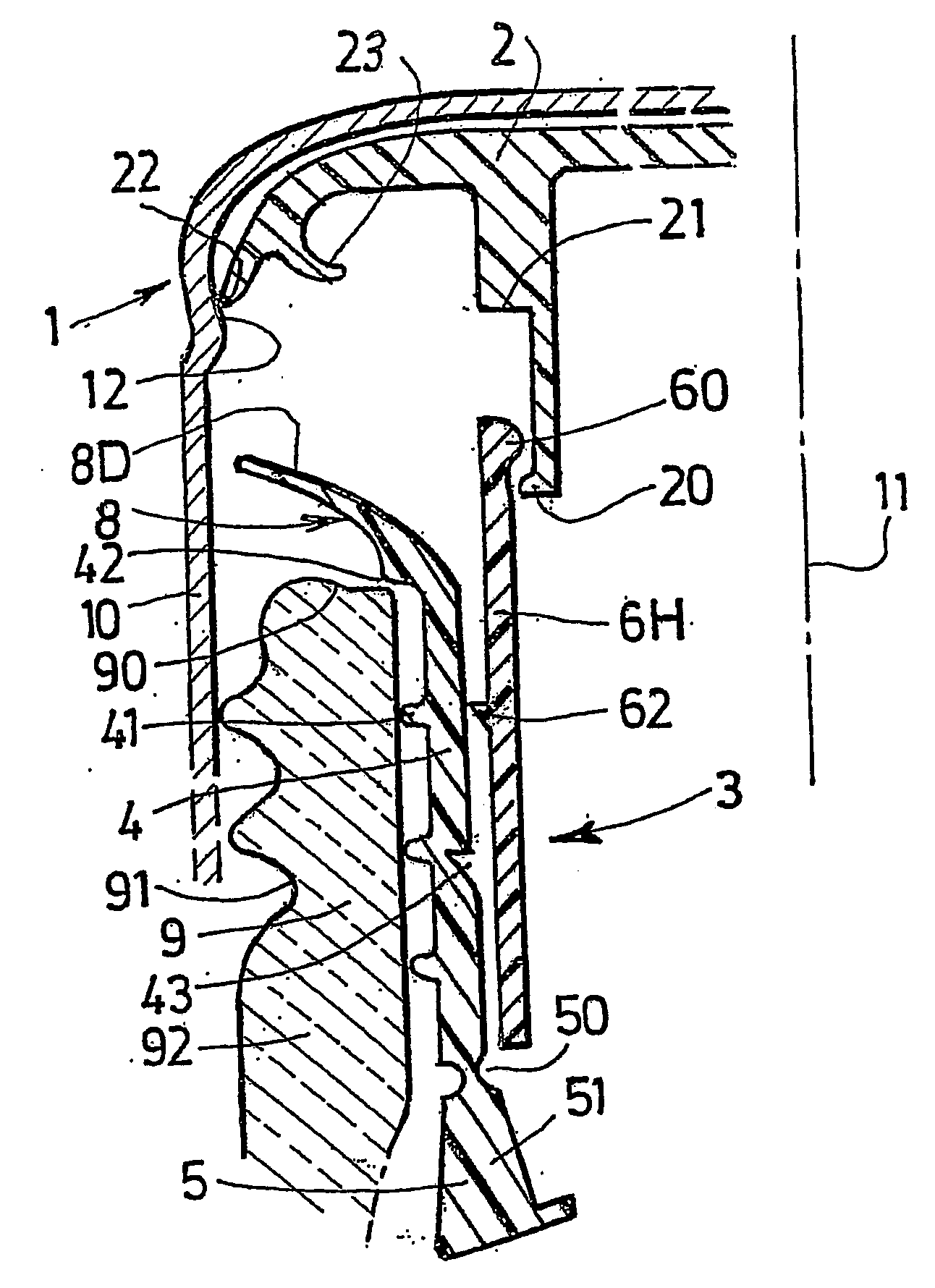

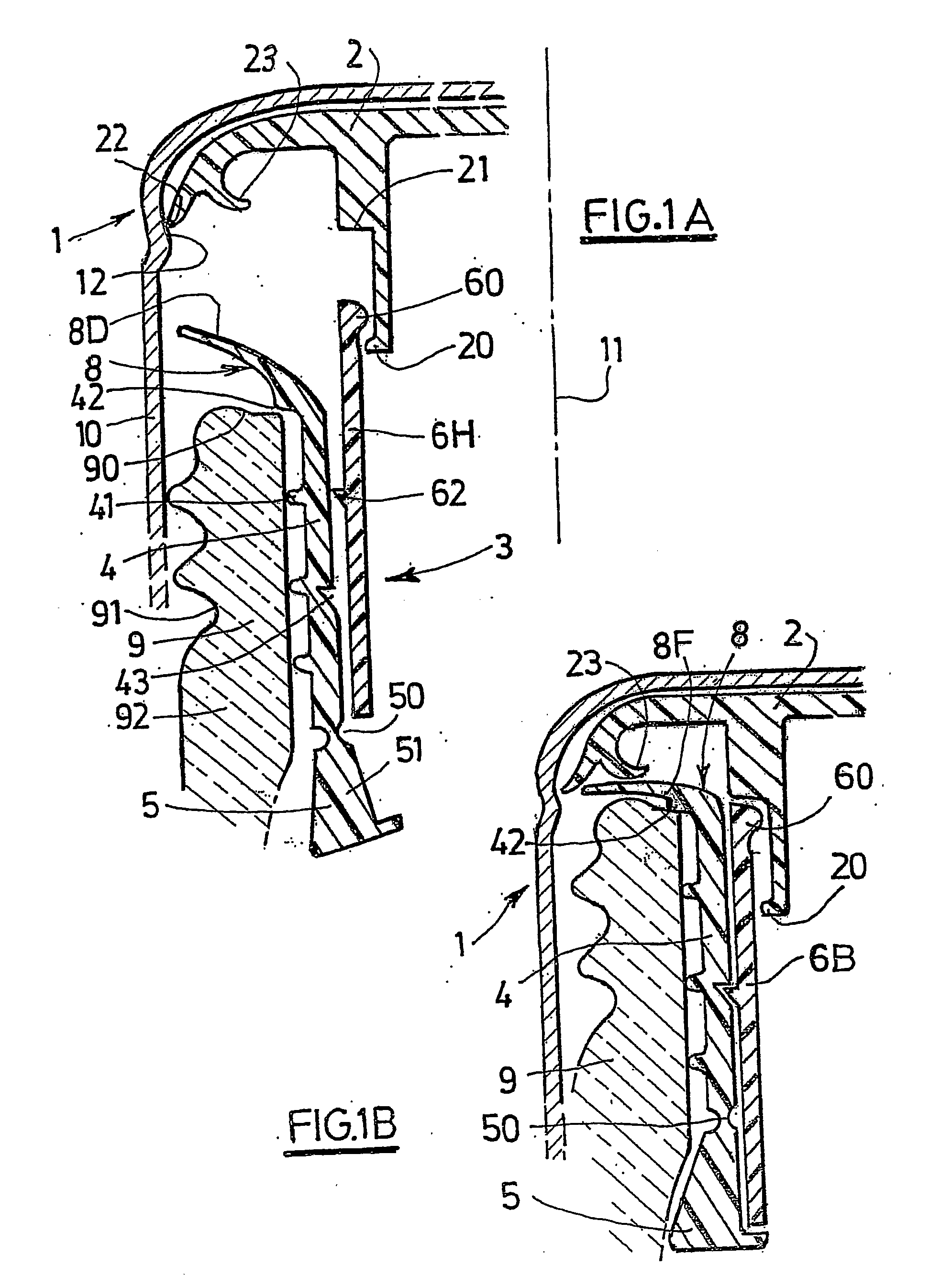

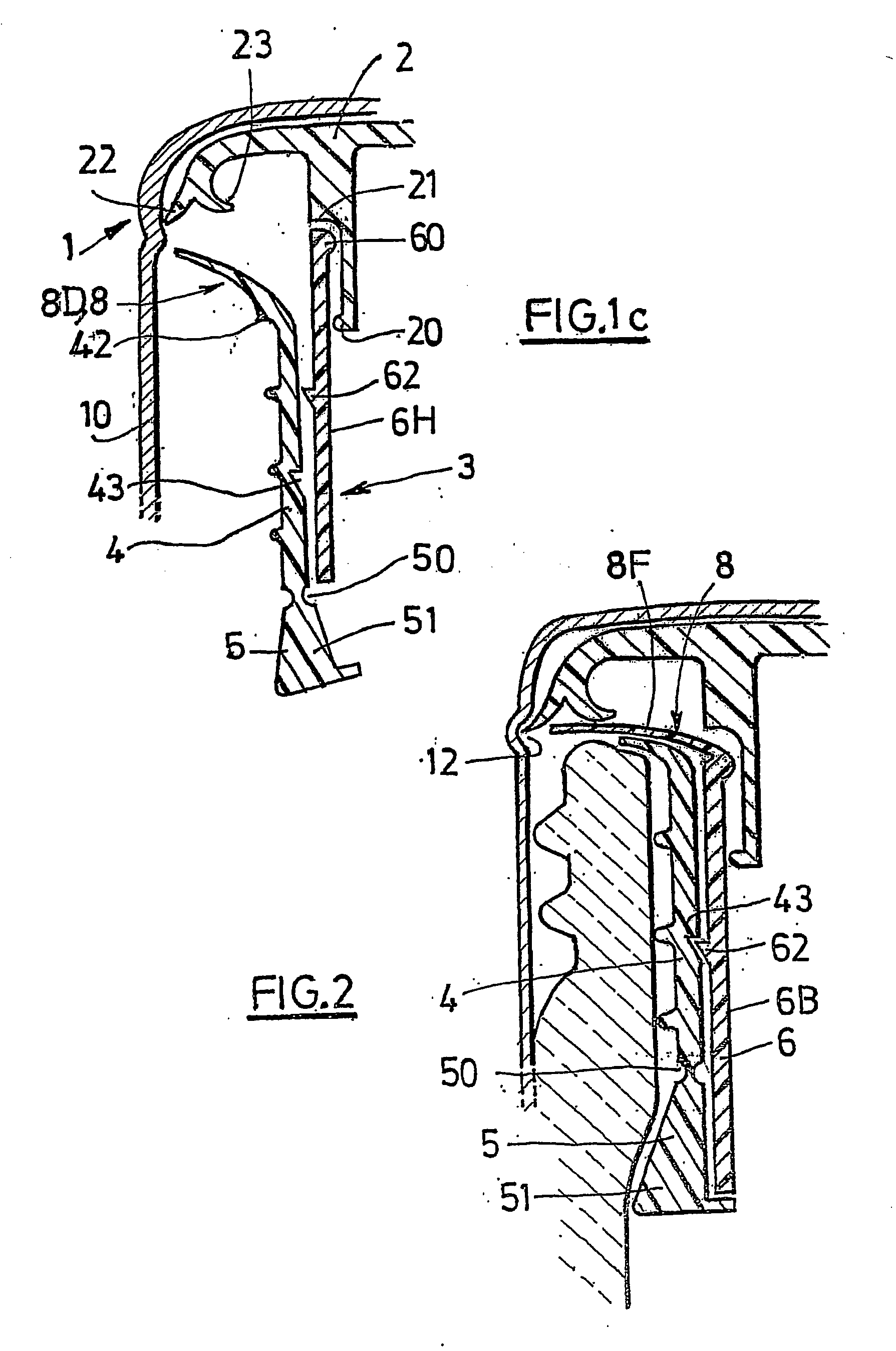

[0073] The figures show example embodiments of caps (1) fitted with inserts (2) and with pourers (3) according to the invention.

[0074] In these examples, all caps and pourers were made for closing necks with an outside diameter of 31.5 mm--see FIG. 7A.

[0075] A conventional shell, typically made of aluminium, was used for the metallic part (10) of the cap.

[0076] As can be seen in the Figures, all the inserts (2) include the following elements:

[0077] 1--a peripheral lip (22) to rigidly fix the insert with the metallic part (10) by means of an annular groove (12), otherwise the insert would have to be glued to the head of the metallic part (10),

[0078] 2--a sealing lip (23) facing inwards and which is preferably compressed in contact with the edge (90) as illustrated in FIGS. 10B to 11B, but possibly in contact with the flexible lip (8F) as illustrated in the other figures.

[0079] 3--a temporary means of assembling the insert (2) to the pourer (3) that solidarises the cap and the pourer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com