Panel roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

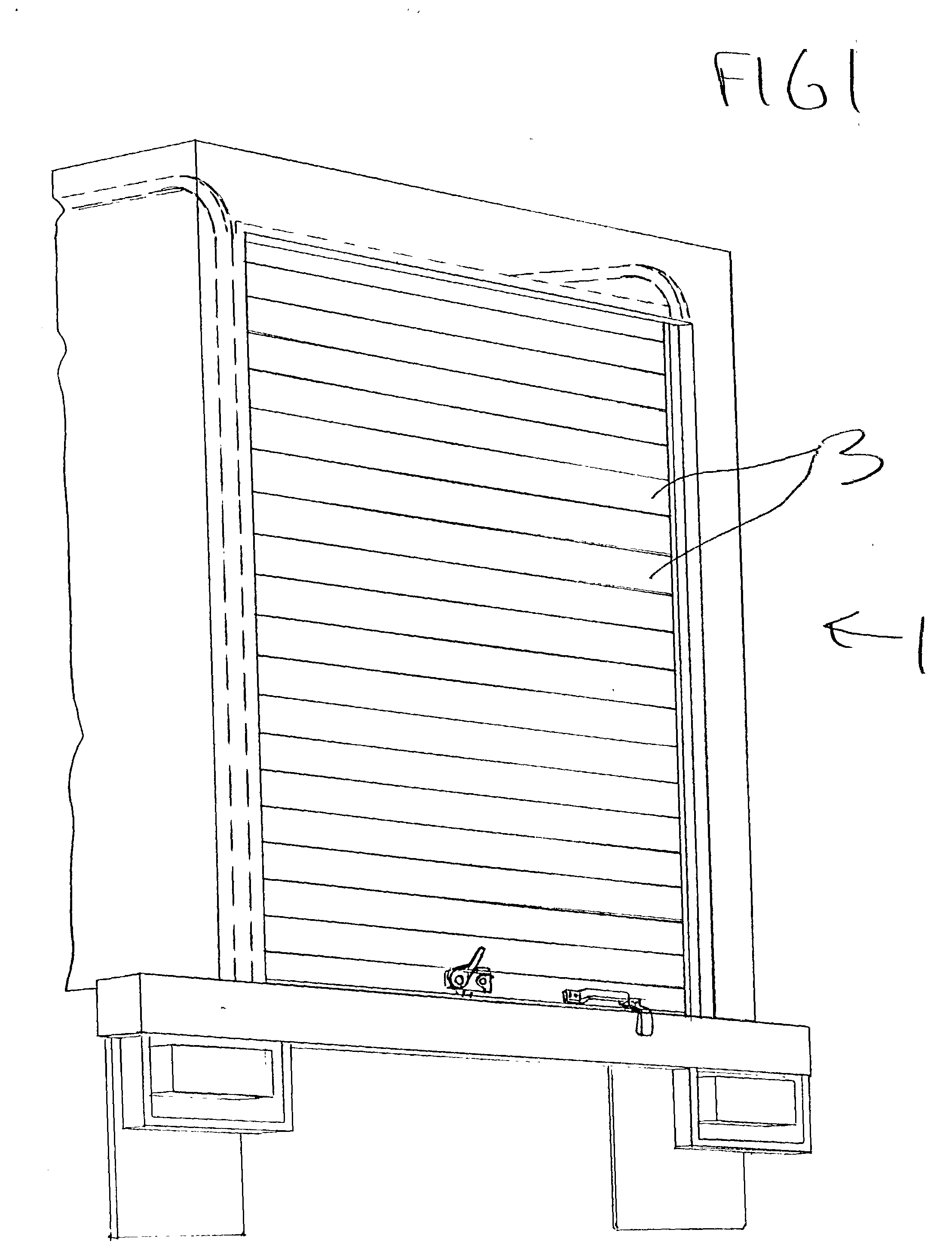

[0021] FIG. 1 shows the rear end of a truck trailer. The truck trailer is opened and closed by a rolling door generally indicated at 1. This rolling door comprises a plurality of panels 3 hingedly secured to one another. The panels preferably have a resin construction.

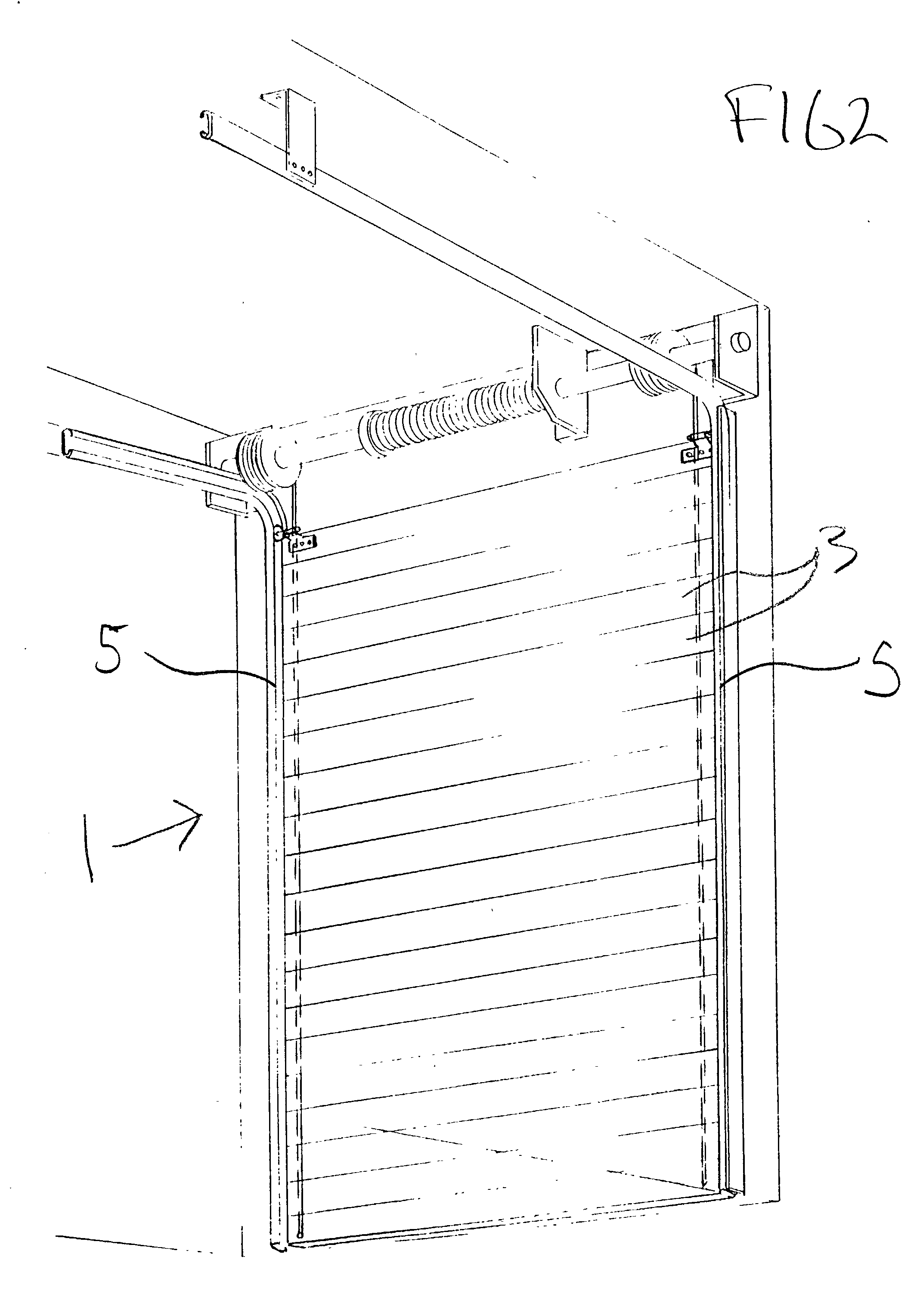

[0022] FIG. 2 shows that the trailer to the inside of door 1 is provided with a pair guide channels 5 to each side of the door.

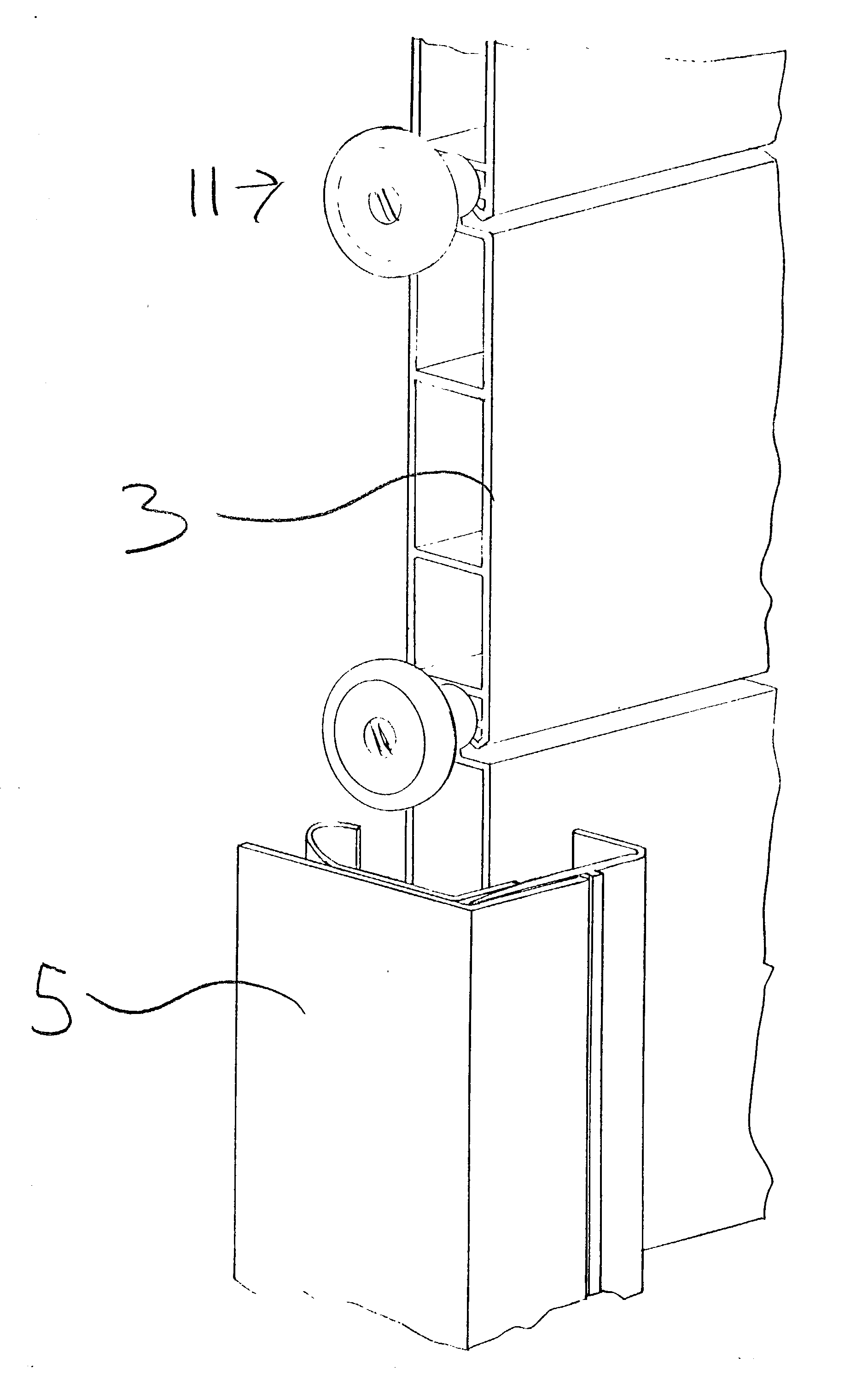

[0023] As will be seen in FIG. 3 of the drawings rollers 11 ride the panels 3 along the guide channels 5.

[0024] FIGS. 4 and 5 of the drawings show that each of the panels 3 is provided to one end with a hollow head 7 and to the other end with an undercut opening 11. Head 7 slides into opening 11 to provide a hinged connection between the adjacent panels as shown in FIG. 5 of the drawings. The hollow head 7 provides an opening 9 for receiving one of the rollers 11 between each of the panels at opposite sides of the door.

[0025] The roller itself is best described having reference to FIGS. 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com