Device for continous or semi-continous casting of metal material

a technology of metal materials and casting strands, applied in the direction of devices for continuous or semi-continuous casting of metal materials, etc., can solve the problems of reducing risk, harmful inclusions in finished cast strands, and affecting the magnitude and extension of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

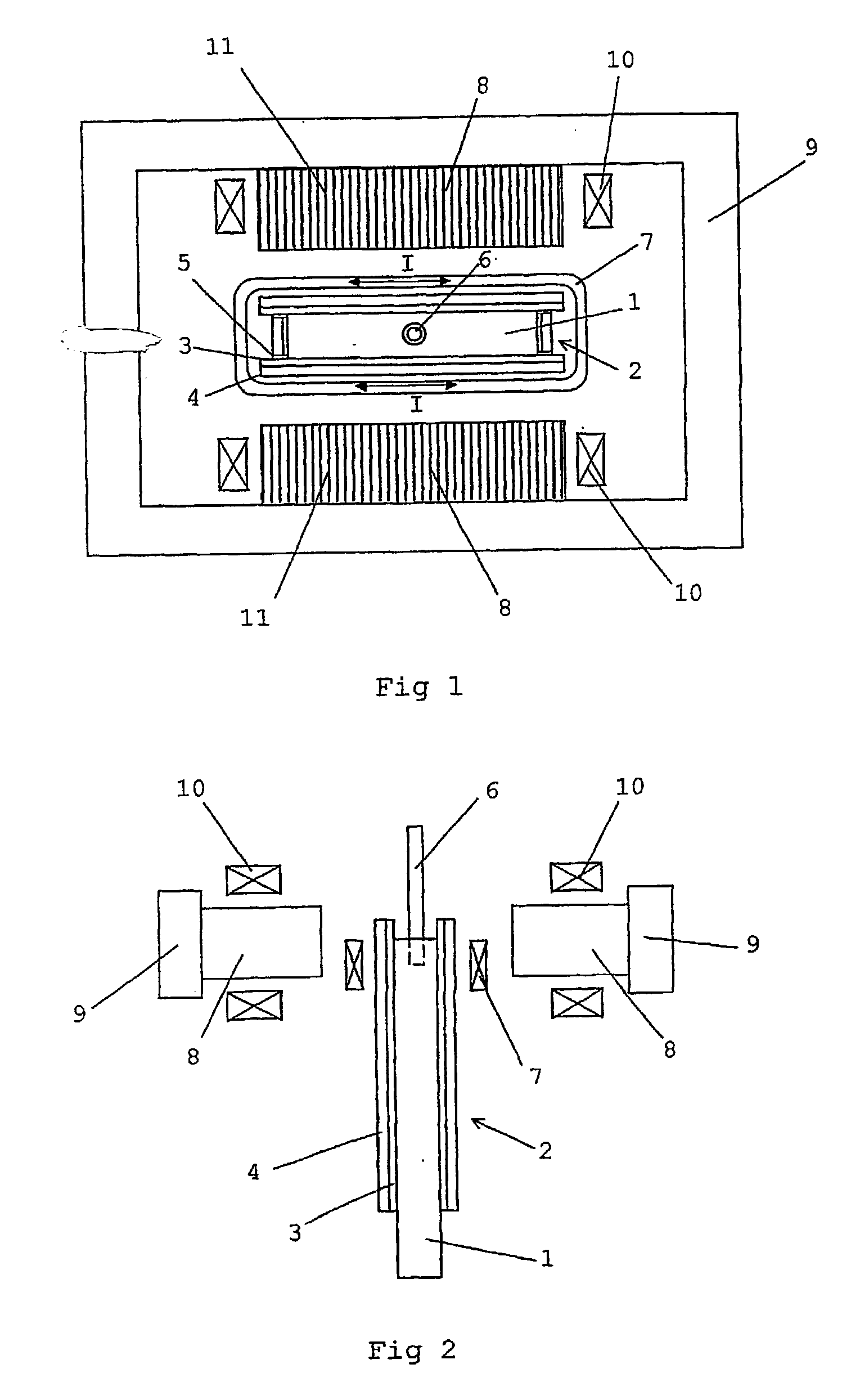

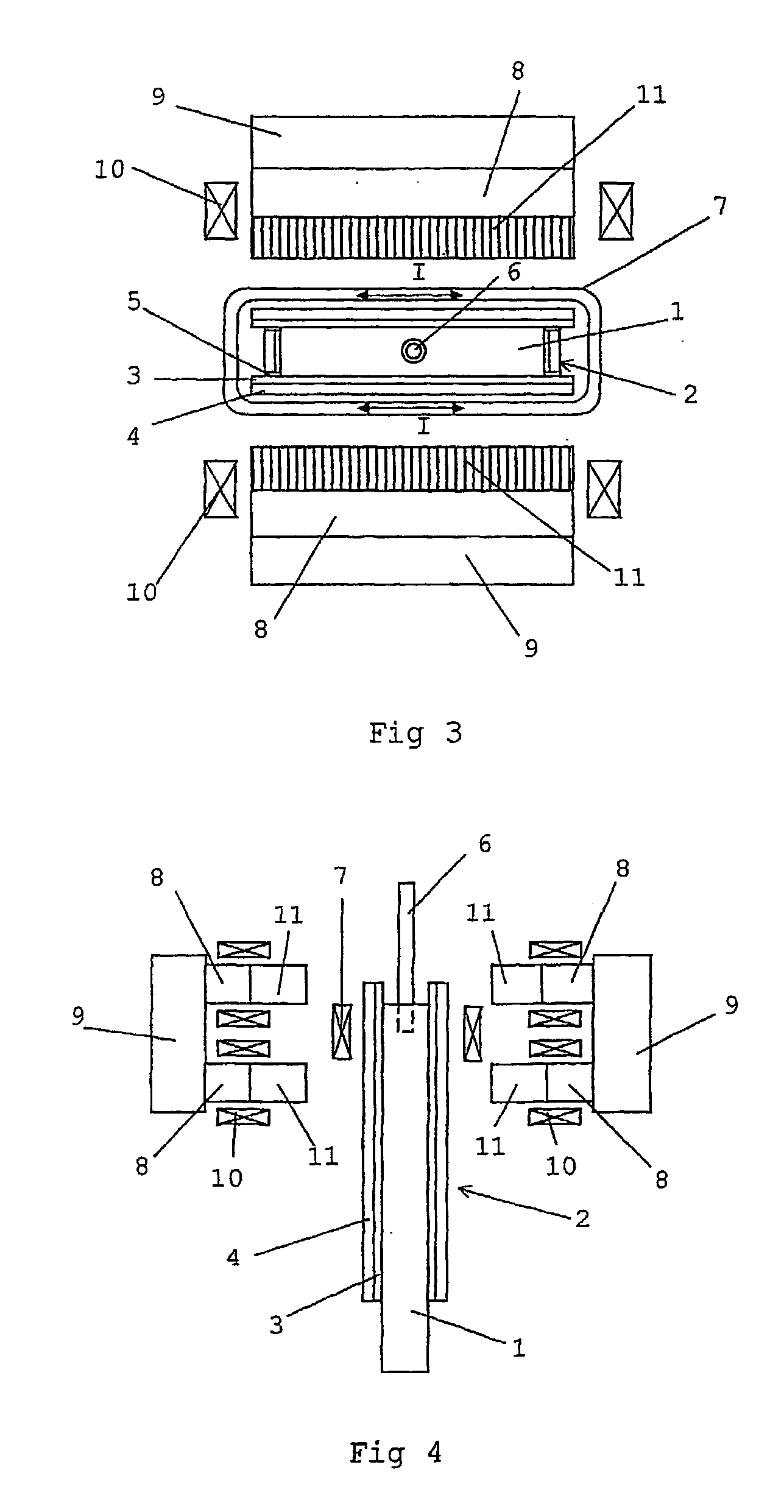

[0023] FIGS. 3 and 4 show the invention. In this case, the laminated portion 11 constitutes only a part of the pole 8. The laminated portion 11 is the part of the pole 8, which is, located nearest the coil 7 and consequently, the part of the pole 8 which is subjected to the heaviest varying magnetic field. In many cases, it is quite sufficient to laminate only such a portion 11 of the poles 8. The second arrangement comprises here four poles 8. Two poles 8 are provided at each side of the mould 2. A yoke 9 connects the two poles 8, which are provided at the same side of the mould 2 to each other. The poles 8 provided at the same side is located at different levels in relation to the mould 2 and have each an extension along substantially the whole width of the mould 2. The coils 10 are provided around each of the poles 8. By feeding the coils 10 with a direct current or a low-frequency alternating current, two parallel static or periodic low-frequency magnetic field at different leve...

third embodiment

[0024] FIGS. 5 and 6 show the invention. In this case the whole poles 8 comprises a laminated portion 11. The poles 8 are provided with recesses 12, which are arranged to receive the coil 7. Here, the poles 8 and the coil 7 consist of an integrated part. Thus, the device becomes compact and requires thereby a relatively small space. Furthermore, a smaller air-gap between the end surfaces of the poles 8 is obtained than in the above-described embodiments. By that fact, just as much electric energy does not need to be supplied to the coils 10 for providing a required magnetic field in the air-gap for the casting process. The second arrangement comprises here four poles 8. Two poles 8 are provided at each side of the mould 2. A yoke 9 connects the two poles 8, which are provided at the same side of the mould to each other. The two poles 8, which are provided at the same side, are located at the same level and have an extension along a part of the width of the mould 2. Coils 10 are prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com