System and method for removing SOx and particulate matter from an emission control device

a technology of emission control device and emission control system, which is applied in the direction of exhaust treatment electric control, separation process, instruments, etc., can solve the problems of increasing the hydrocarbon emissions during the regeneration of the particulate filter, the known control system, and the drawback of the engine fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

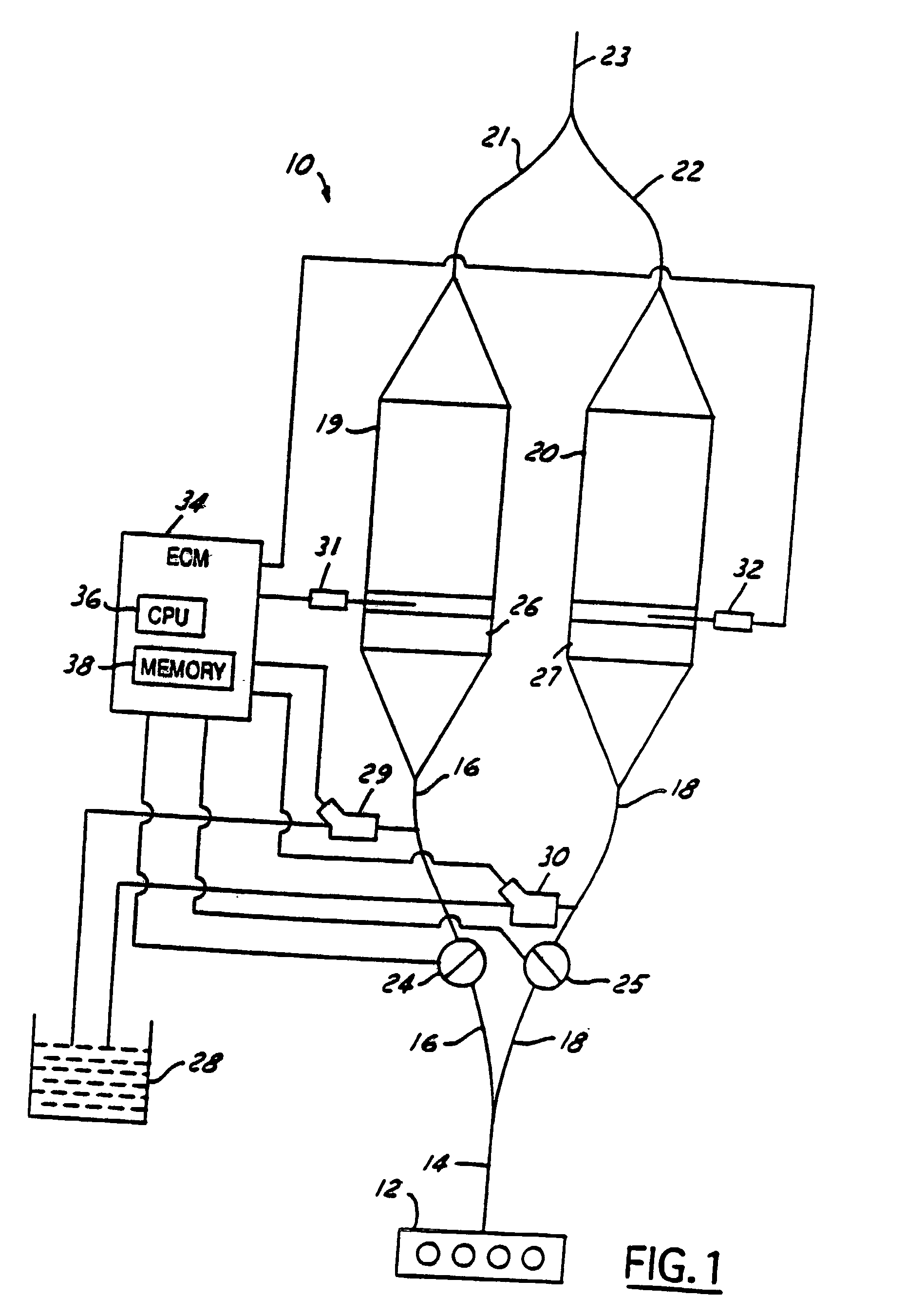

[0014] Referring now to FIG. 1, an exhaust system 10 is illustrated in operational relationship with an internal combustion engine 12 such as a diesel engine for a vehicle such as an automotive vehicle (not shown). The engine 12 has an exhaust manifold 14 to direct the exhaust gases from engine 12 to exhaust system 10. The exhaust manifold 14 is divided into two exhaust intake conduits 16, 18. The exhaust intake conduits 16, 18 direct exhaust gases through two integrated NO.sub.x trap / particulate filters 19, 20. The outputs of the filters 19, 20 are directed through two exhaust output conduits 21, 22 to a muffler or tail pipe 23. The amount of exhaust gases flowing to filters 19, 20 is controlled by control valves 24, 25, respectively. Conventional oxidation catalysts 26, 27 are located upstream and proximate filters 19, 20, respectively.

[0015] The oxidation catalysts 26, 27 serve several functions. First, catalysts 26, 27 are utilized to accurately control temperatures in filters 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com