Laminated edge filter structure and method of making

a technology filter element, applied in the field of laminated edge filter element structure and method of making, can solve the problems of filter failure test, membranes are relatively weak and fragile, and membranes do not seal well with potting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Samples according to the Present Invention

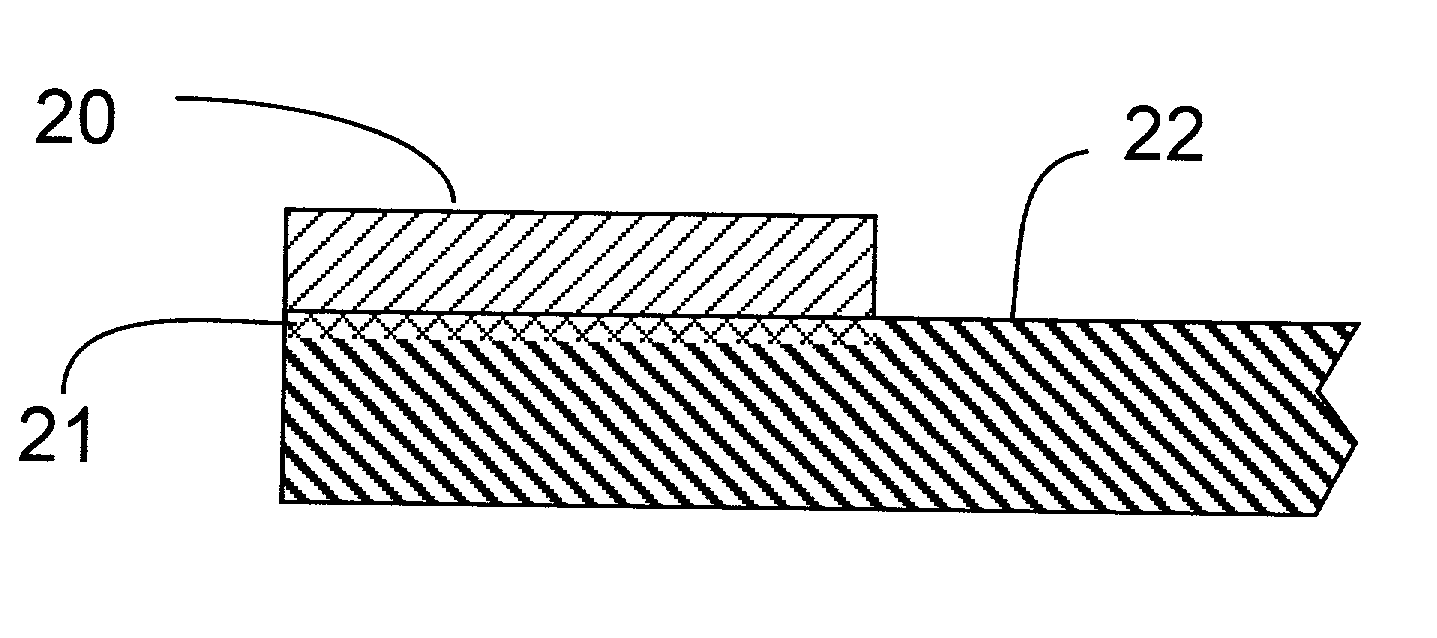

[0052] Hydrophilic, PVDF membrane, known as Durapore.RTM. membrane available from Millipore Corporation of Bedford, Massachusetts, was sealed at its top and bottom edges on one side with an extrusion laminated strip of polypropylene and subsequently converted into pleated, 10 inch cartridges.

[0053] Control Samples

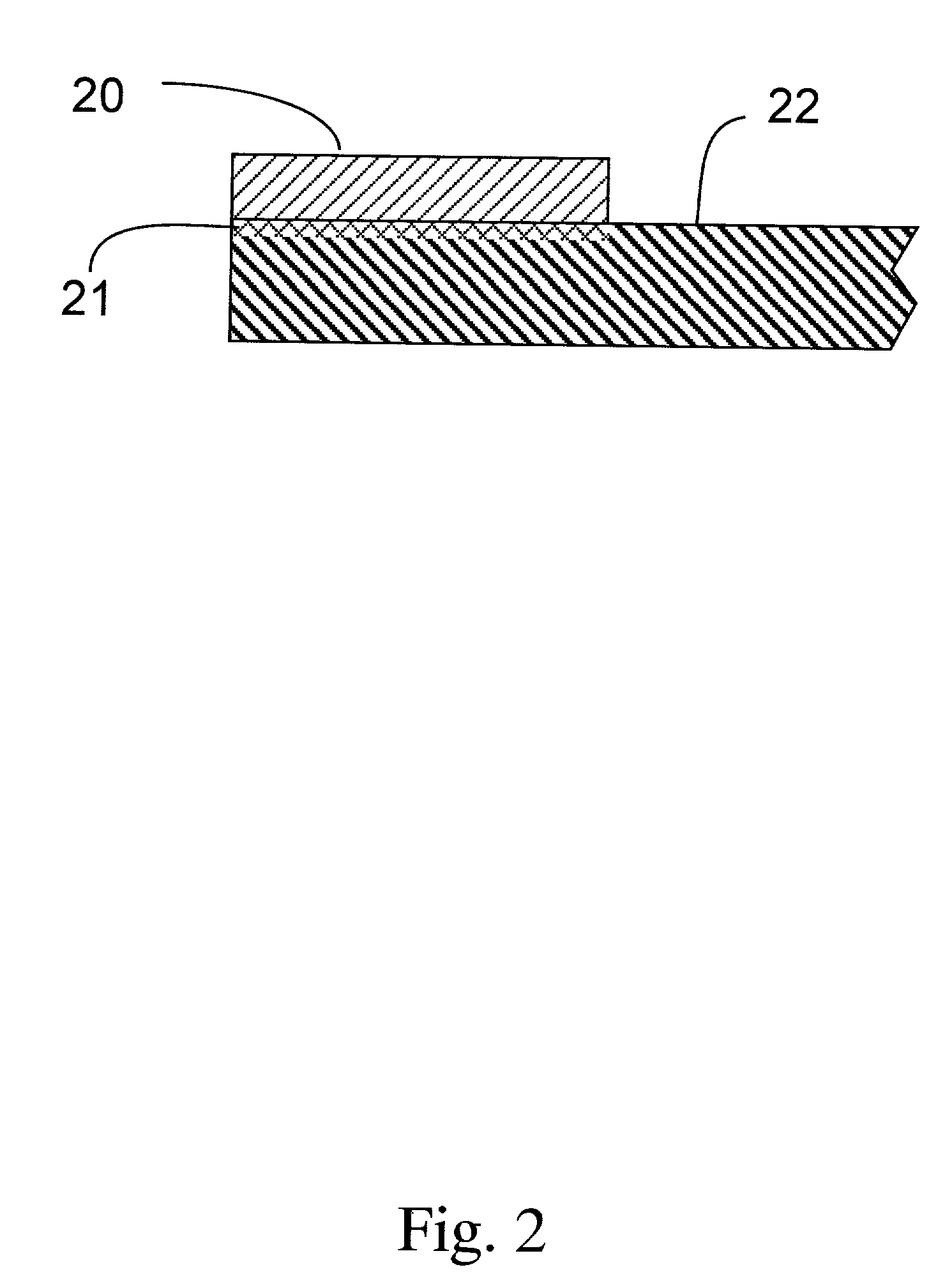

[0054] Hydrophilic, PVDF membrane, from the same manufacturing lot as the above samples was also heat laminated at the top and bottom edges of the membrane on one side, but with a preformed film of polypropylene. This structure was subsequently converted into pleated, 10-inch cartridges for comparison to the above samples.

[0055] Testing

[0056] Both sets of membrane were formed into 10 inch pleated cartridges formed of polypropylene nonwoven support, end caps and cages. All cartridges were formed in the same manner and under the same conditions.

[0057] All cartridges were subjected to a gas diffusion test in which cartridge inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com