Portable modular factory structure and method of constructing same

a factory structure and modular technology, applied in special buildings, parkings, building repairs, etc., can solve the problems of reducing anticipated profits, increasing construction costs, and common problems inherent in conventional construction of houses or other structures, and achieving the effect of being ready for transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the ensuing description of the invention the term "building" is sometimes used to refer to a factory or a plant constructed by the method of the present invention. Also the terms "shipping containers" and "storage containers" refer to containers generally made of steel. These containers contain various factory components mounted therein at defined positions prior to their transportation to the building site.

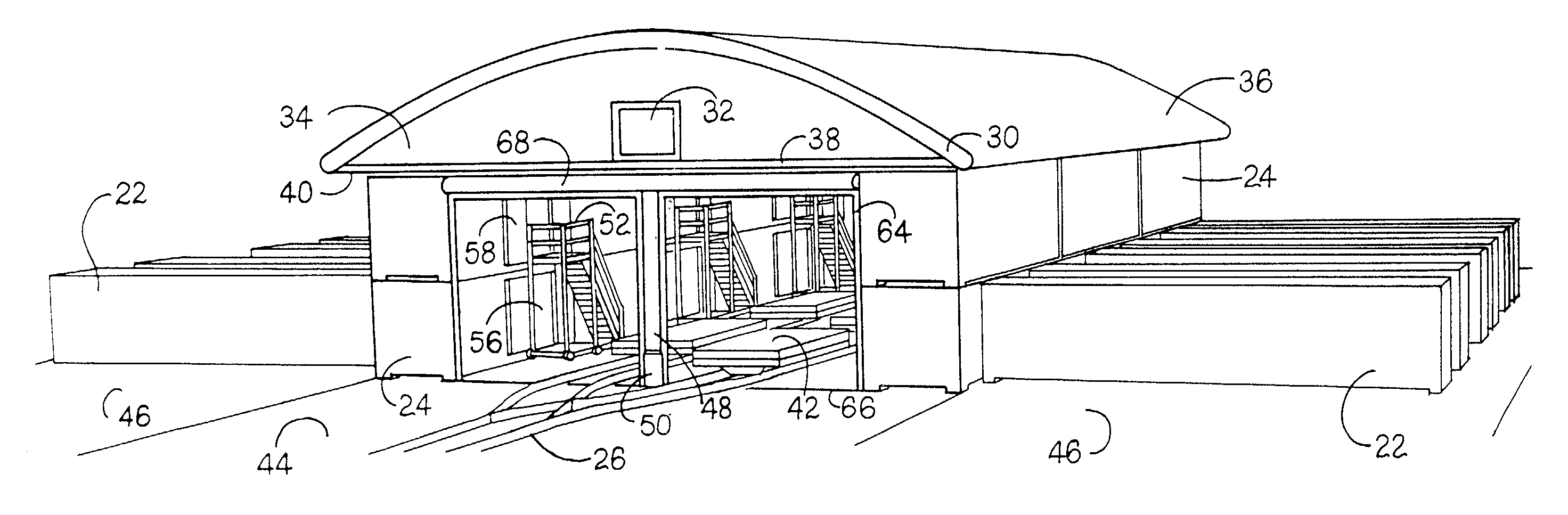

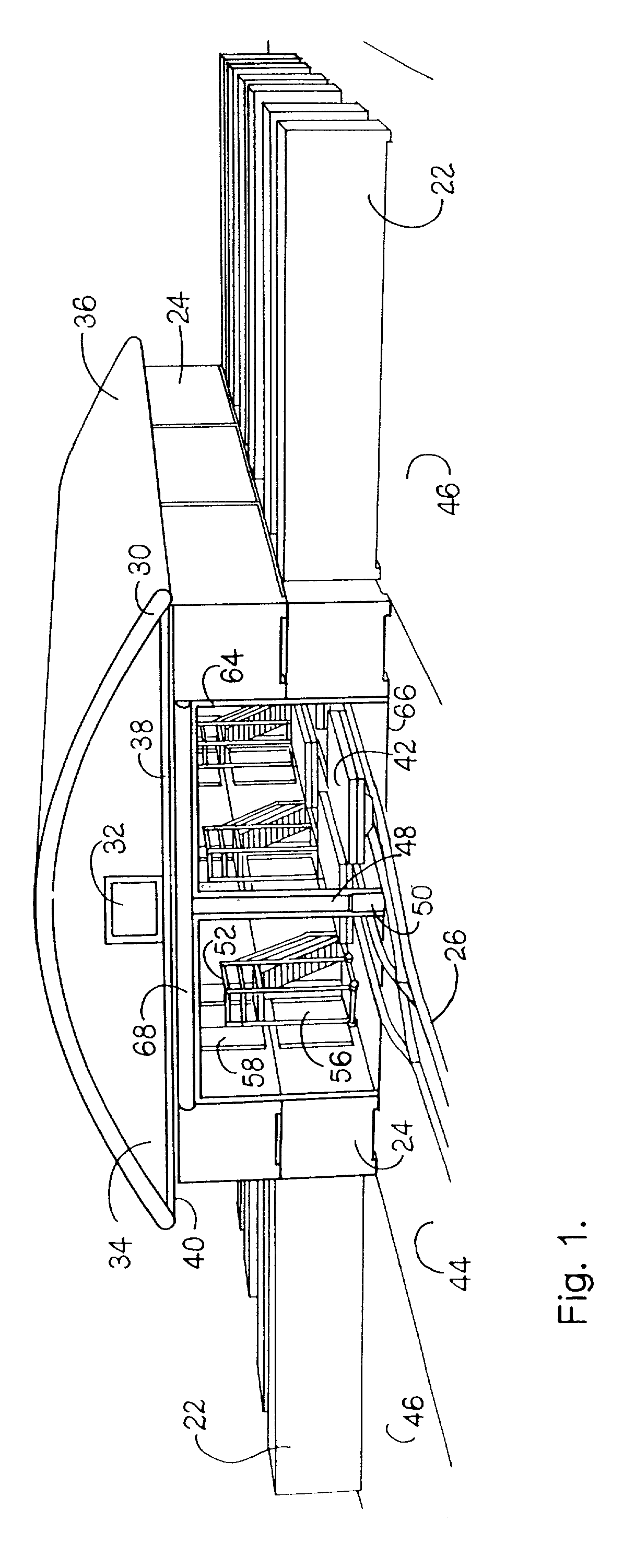

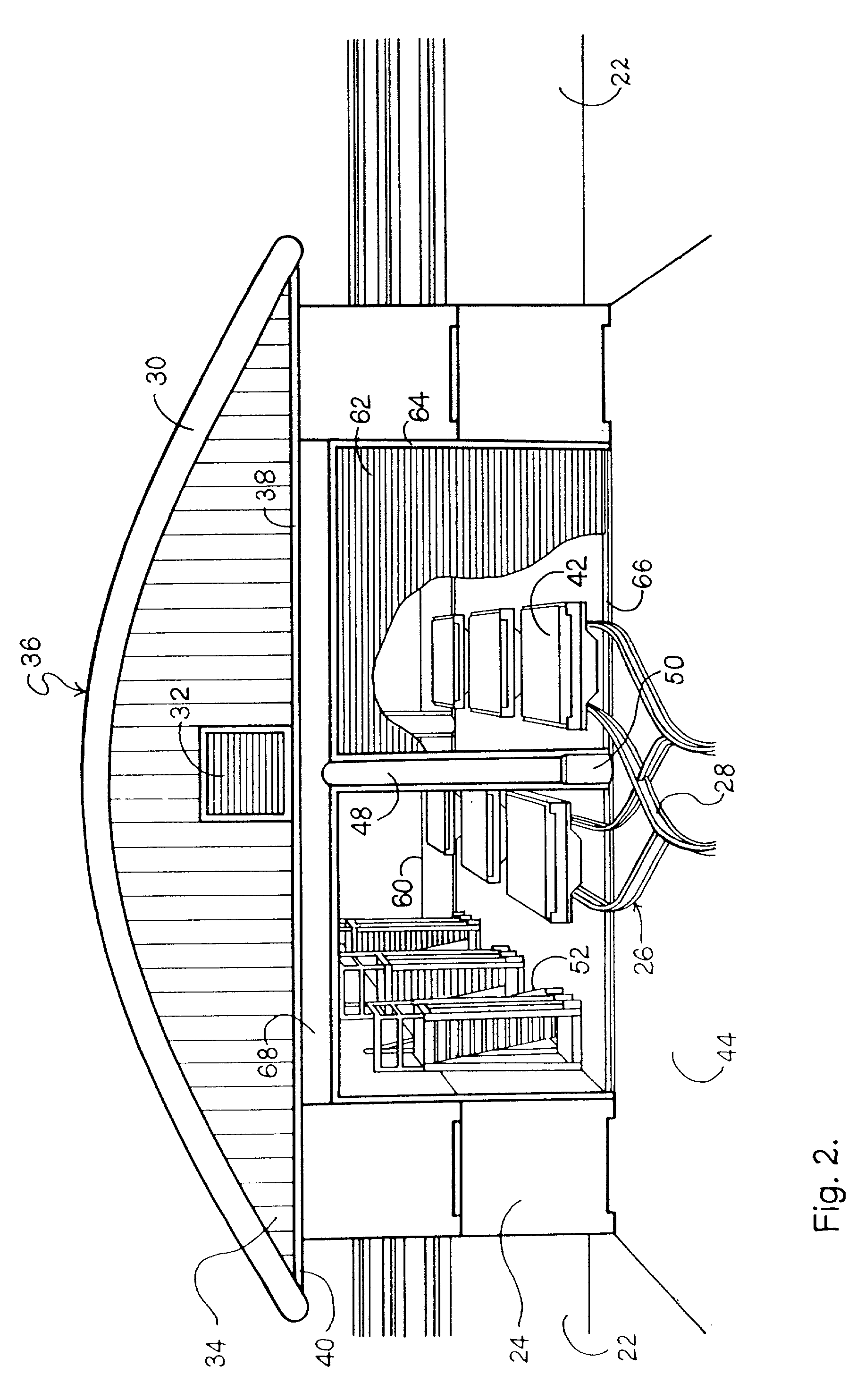

[0042] Referring now to FIGS. 1-3, and in particular to FIG. 1, there is shown steel shipping containers 24 stacked and aligned relative to each other thus forming the major components of the building. The shipping containers 24 are bolted to the primary slab 44 by conventional means, and they abut one another with a gasket to form a weather tight seal. Two sets of steel shipping containers 24 are shown set on the slab 44 in order to define the length of the building. These shipping containers are modified prior to assembly at an offsite location by adding one or more s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com