Variable length truss and method for producing the same

a technology of variable length trusses and trusses, which is applied in the direction of girders, joists, trusses, etc., can solve the problems of requiring old growth timber, requiring inferior nailing surfaces compared with those provided, and causing potential splitting of the channel holding the struts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

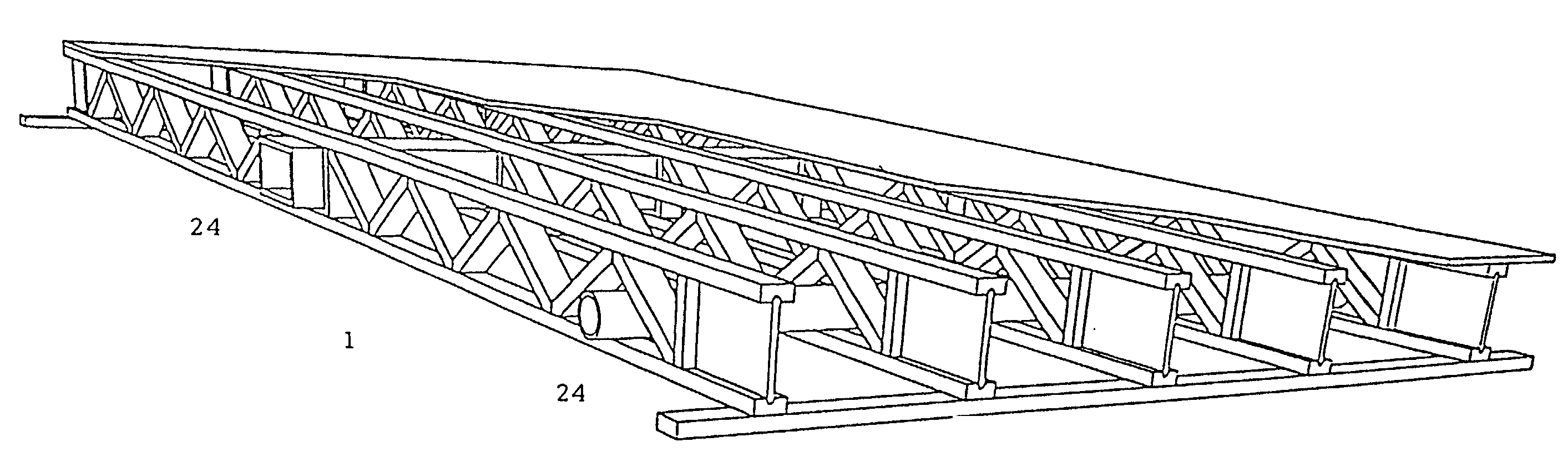

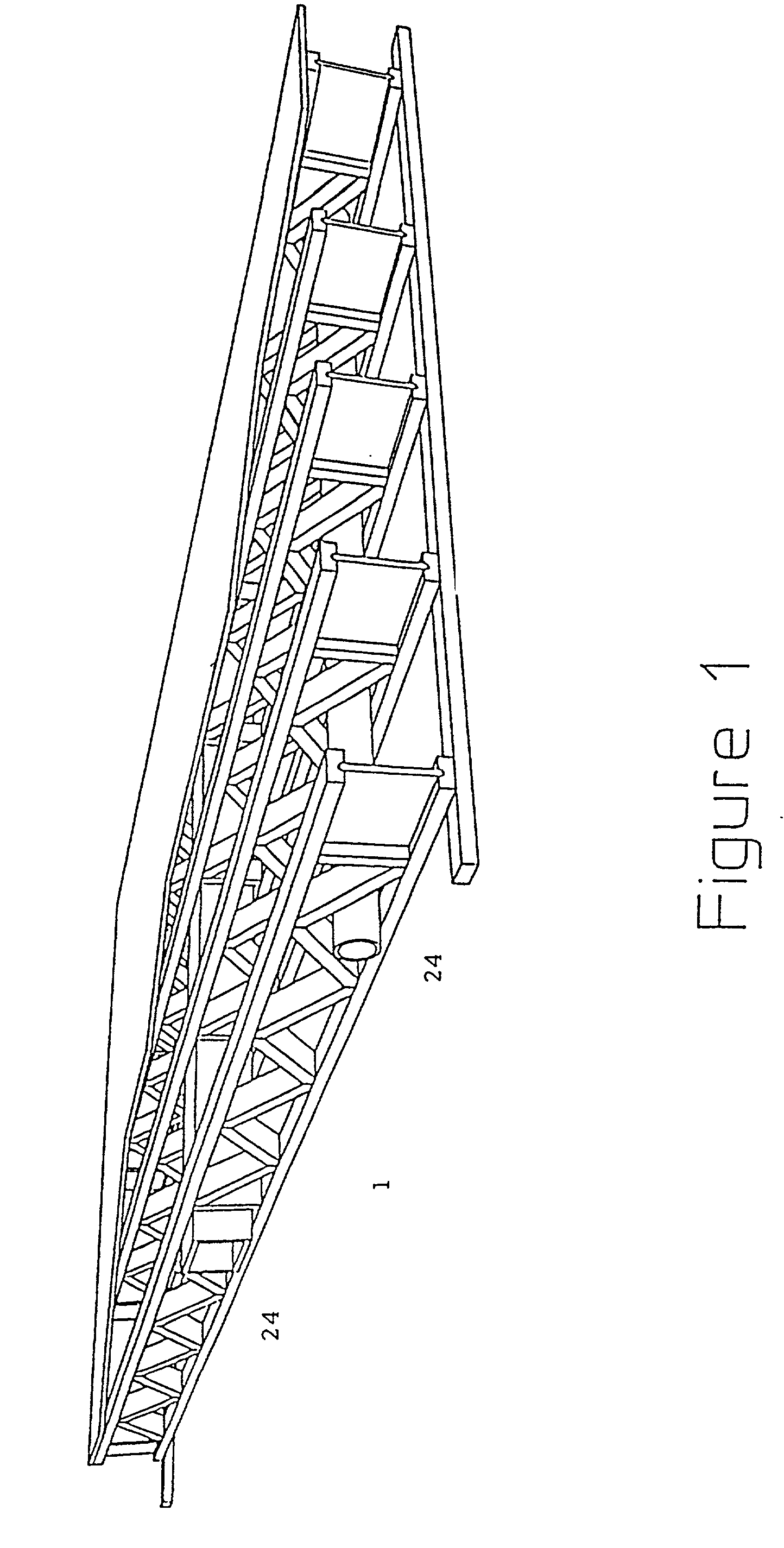

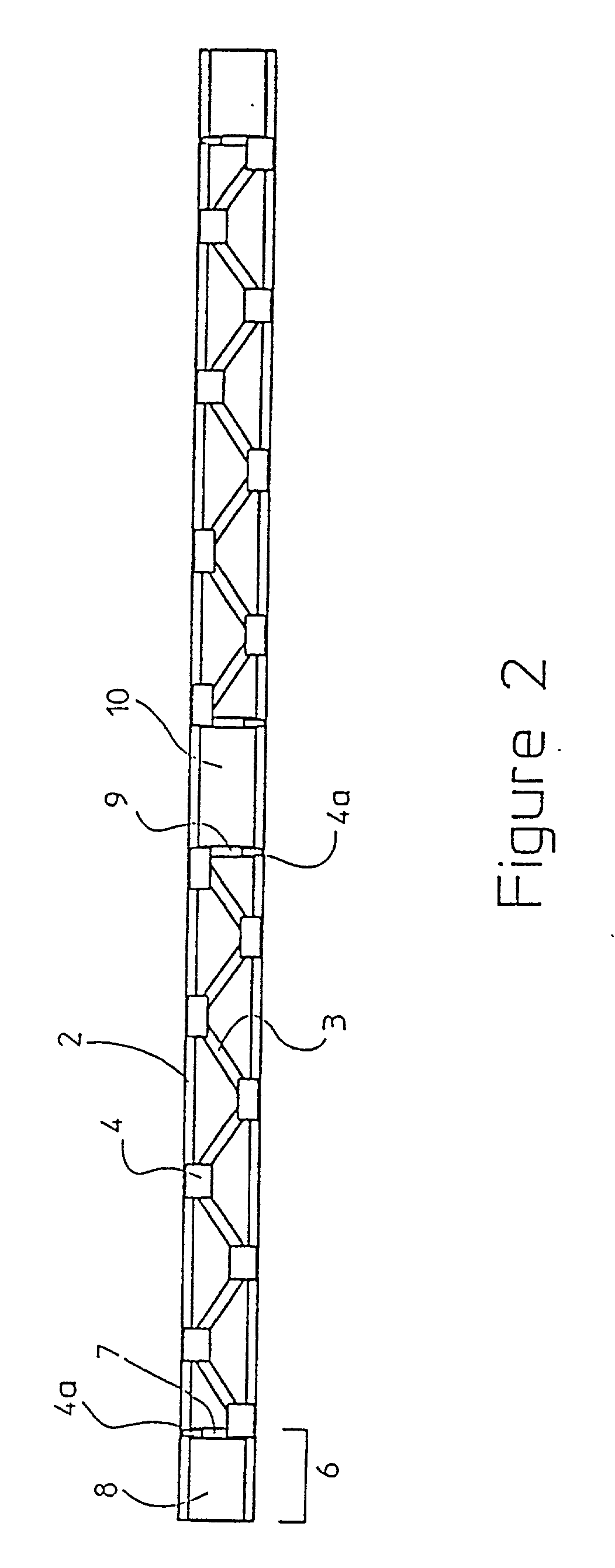

[0058] As can best be seen by reference to FIG. 1, the structural component system 1 is constructed of a series of individual truss members as shown as 2 in FIG. 2 and the ends of the structural component are constructed of wooden flanges separated by a vertical wooden solid web material.

[0059] As can best be seen by FIG. 2, each of the cross member 3 is constructed generally using cross beams 3 and chords 5. An end unit 6 comprised of a strut 7 and a closed web 8 complete the interior portions. The chords are bound to the struts 7 and the cross members 3 utilizing metal fasteners 4. These fastener 4 are known in the art and appear as a metal sheet out of which sharp points or nails have been punched. Typically, these fasteners 4 need to be in place on both sides of the cross beams 3, struts 7 and chords 11 and 12. A smaller fastener 4a is used in order to secure the top or bottom of vertical beams 9 defining duct opening 10 and the top of struts 7.

[0060] The strut may be slanted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com