Device for holding cams during their binding on a tube by expansion of the tube

a technology of expansion tube and camshaft, which is applied in the direction of mechanical equipment, manufacturing tools, metal-working machine components, etc., can solve the problems of cam cracking, cam manufacturing precision being insufficient, and cams are less resistant to sintered cams than cams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

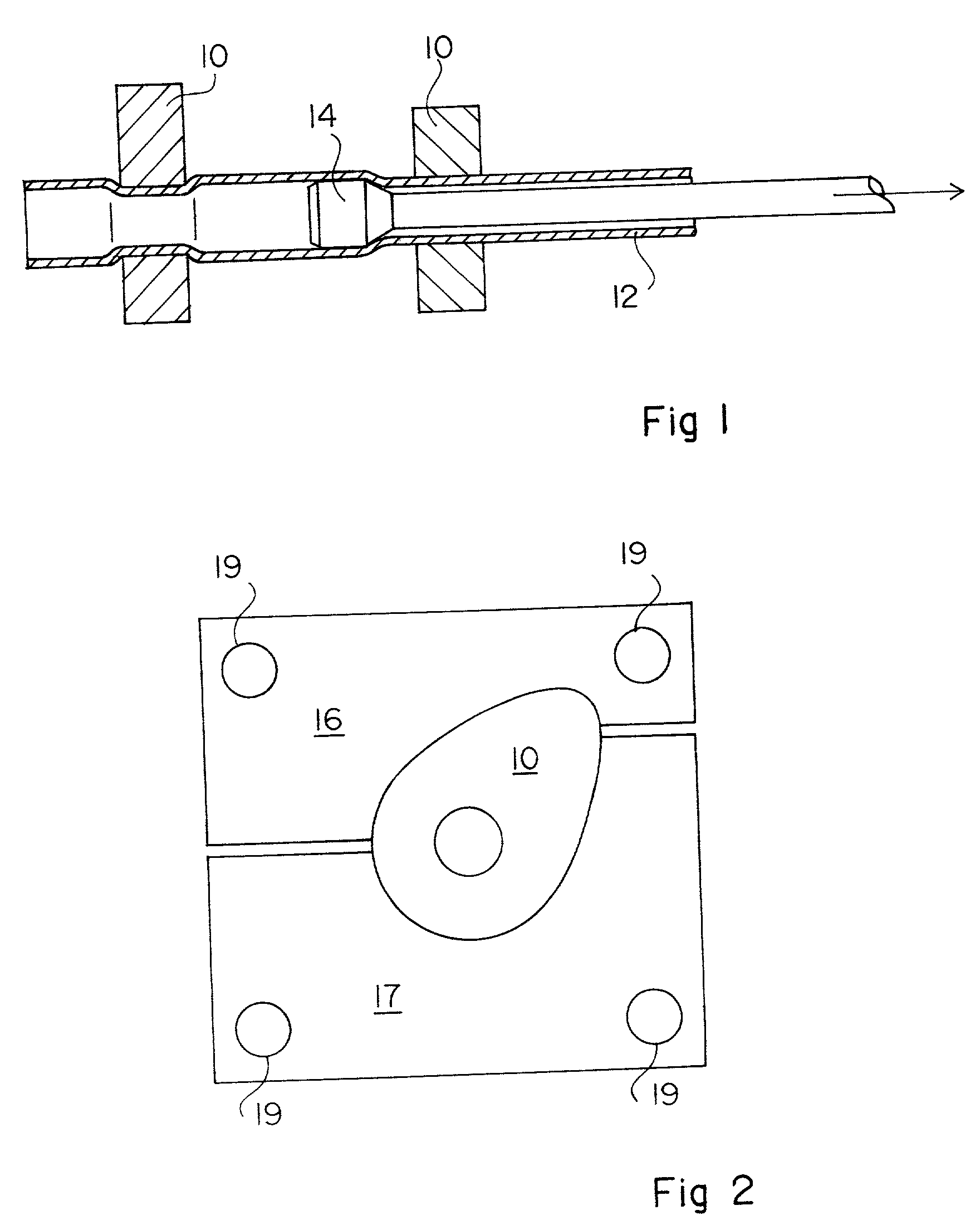

[0022] The present invention is based on an analysis of the phenomena occurring during the binding when using a cam holding device of the type in FIG. 2.

[0023] When several juxtaposed blocks of the type in FIG. 2 are used to hold several cams along a tube, the cams having the smallest dimensions in the admitted tolerance range appear to be arranged with a play between their blocks. Indeed, when the two half-cases formed by the juxtaposition of the blocks bear against each other, only two cams are held with no play between their two blocks. However, the other cams, held with a play, do not crack. This shows that a certain peripheral play can be left between the cam and the two blocks without risking breakage during the binding.

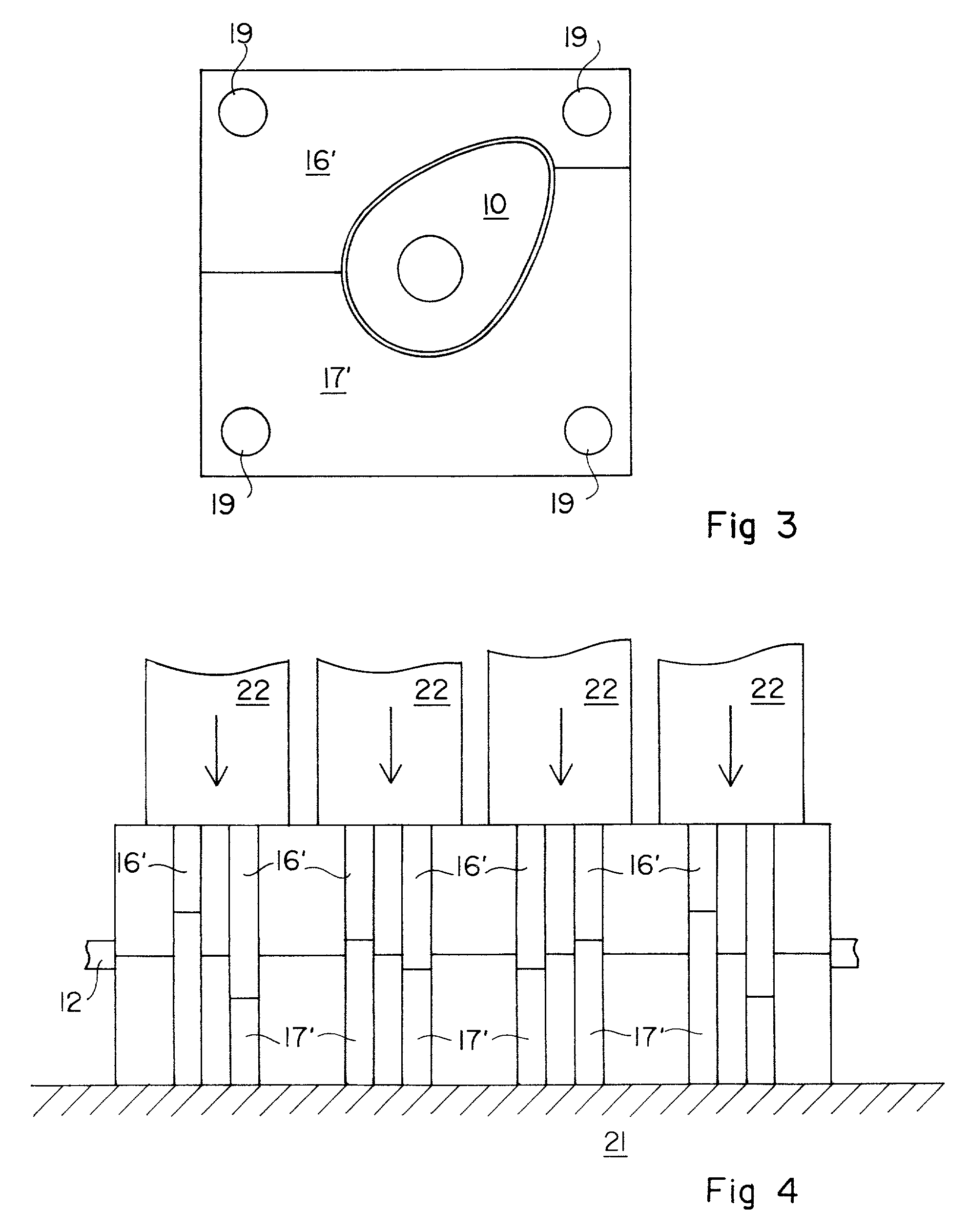

[0024] The present invention provides suppressing the play at the level of the parting line and holding all cams with a peripheral play. Conversely to what could be expected, the accuracy of the angular positioning is thus improved.

[0025] FIG. 3 shows an exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com