Bi-directional cable guard

a cable guard and bi-directional technology, applied in the direction of pipe protection, drilling pipes, mechanical equipment, etc., can solve the problems of uncontrollable detachment of the base and clamp, damage to the cable guard and cables, and loose taper pins, etc., to achieve the effect of quick installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

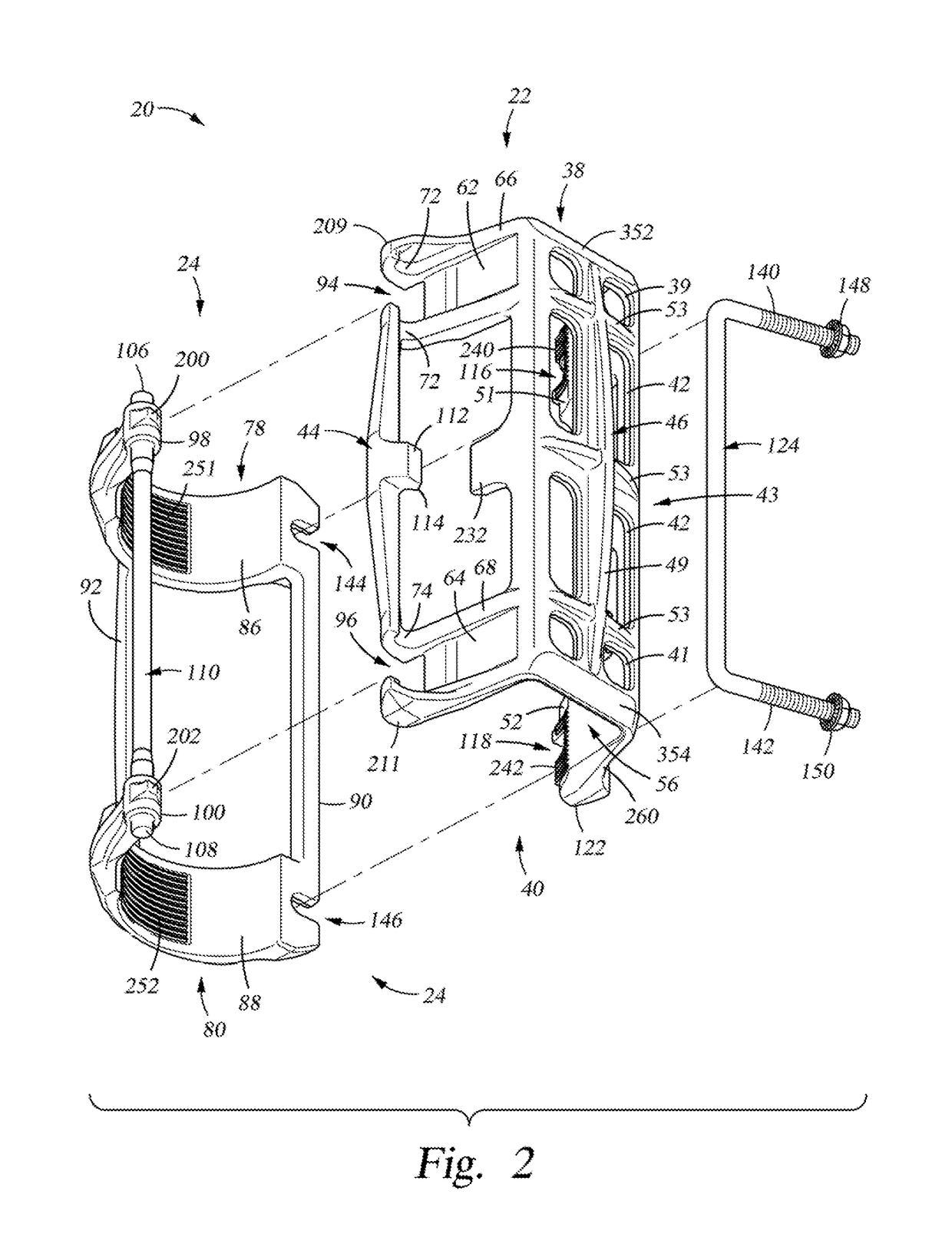

[0100]Referring to FIG. 1, a rig is engaged to a first tube 28 and a second tube 30, the tubes 28 and 30, that are removably connected to each other by a coupling 26 comprising a tubing string 32, and while coupling 26 is shown in the figures with squared ends, in practice coupling 26 may be integral and smoothly transition to tubes 28 and 30. FIG. 1 also shows a first cable 34 and a second cable 36, the cables 34 and 36, and a cable guard 20 enclosing cables 34 and 36 installed along tubing string 32. Referring to FIG. 1, below the deck, a cable guard 20 is deployed in a well bore 33. Typically, a well system 10 comprises tubing string 32 and cables 34 and 36 along tubing string 32, including cable guards 20 secured to the tubing string 32 that protect cables 34 and 36 extending to downhole equipment.

second embodiment

[0101]In general, referring to FIG. 1, the present invention is comprised of a base 22 and a ring 24 that are rotabably and removably connected to each other and adapted for mounting on tubing string 32, and a u-bolt 124 having threaded legs with nuts, described below, that is rotabably and removably connected to base 22; and, alternatively, in a second embodiment, u-bolt 124′ is rotabably and removably to ring 24′, for securing cable guard 20′ to tubing string 32′. Referring to FIG. 1, cable guard 20 is installed around coupling 26. The present invention may also be mounted on a tube and / or connected in tandem for protecting cables.

[0102]While the terms tube 28 and tubes 28 and 30 and tubing string 32 are related to each other as a tubing string 32 is comprised of tubes 28 and 30 and couplings 26, all embodiments of the present invention are capable of protecting cables 34 and 36 by mounting present invention on a tube 28 or on tubes 28 and / or 30 across a coupling 26. Similarly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com