A continuous microwave solid-liquid extraction system

A microwave and extraction technology, applied in the field of continuous microwave solid-liquid extraction system, can solve problems such as inability to realize large-scale production, and achieve the effects of reduced space, reduced processing difficulty, and compact system equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

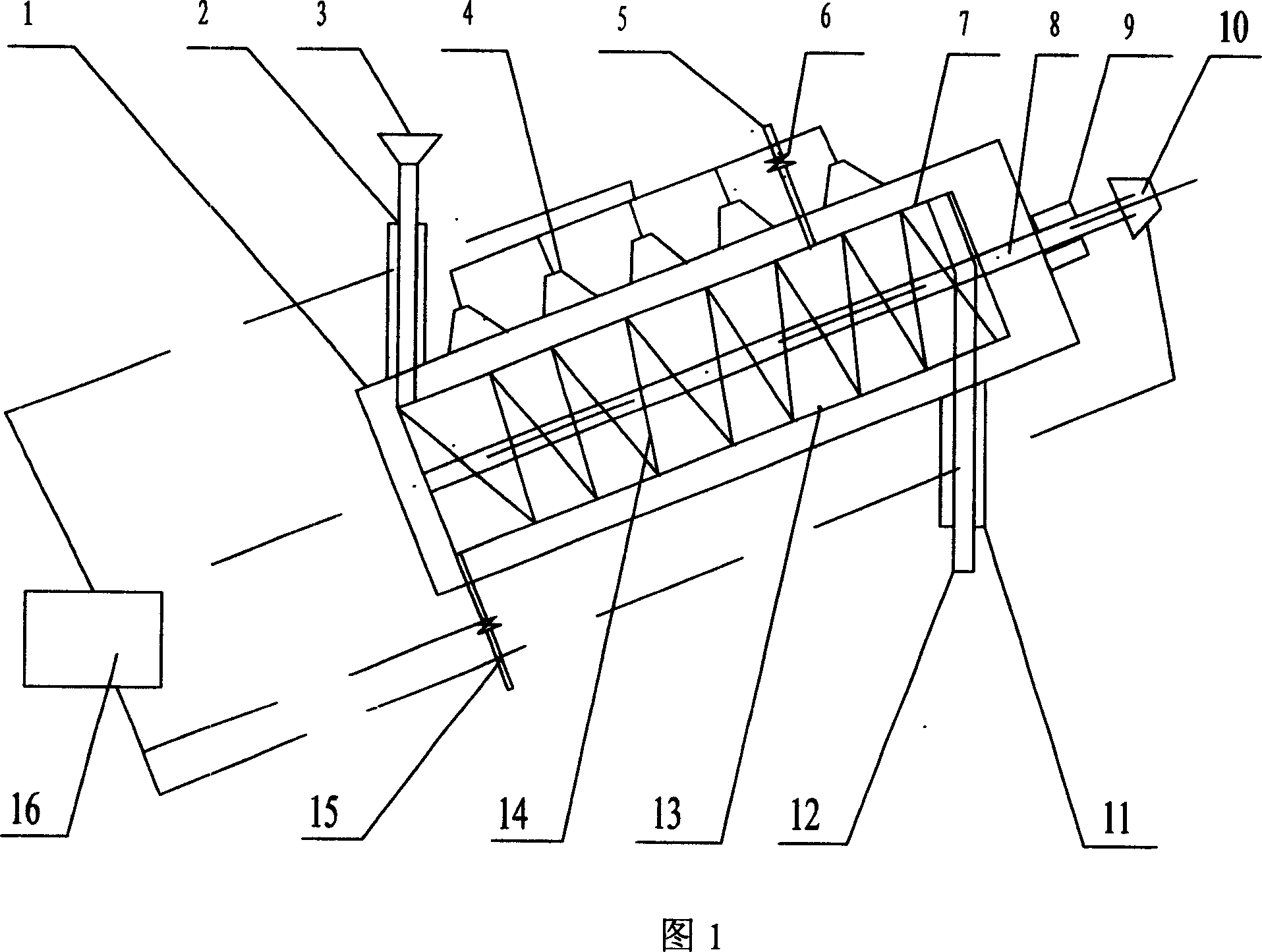

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments, but the implementation of the present invention is not limited thereto.

[0017] As shown in Figure 1, a continuous microwave solid-liquid extraction system includes a rectangular hollow cavity 1 with a microwave magnetron 4 on the outside, and an extraction chamber 7, located in the extraction chamber 7 and connected to a rotating shaft 8. A solid-liquid conveying device composed of a transmission blade 14, a rotating shaft 8, a motor driving the rotating shaft 8, and a transmission 10. The extraction chamber 7 and the horizontal plane are at an inclination angle of 15°C. The inclination angle between the extraction chamber 7 and the horizontal plane of the present invention can be any angle from 5 to 80°C. The bottom of the solid-liquid transmission device is provided with a solid material inlet 3 and an extraction liquid juice outlet 15 , The top i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com