Piston pump with improved efficiency

A piston pump, piston technology, applied in the direction of piston pumps, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as noise, unfavorable flow characteristics, etc., achieve compact structure, short response time, and reduced number of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

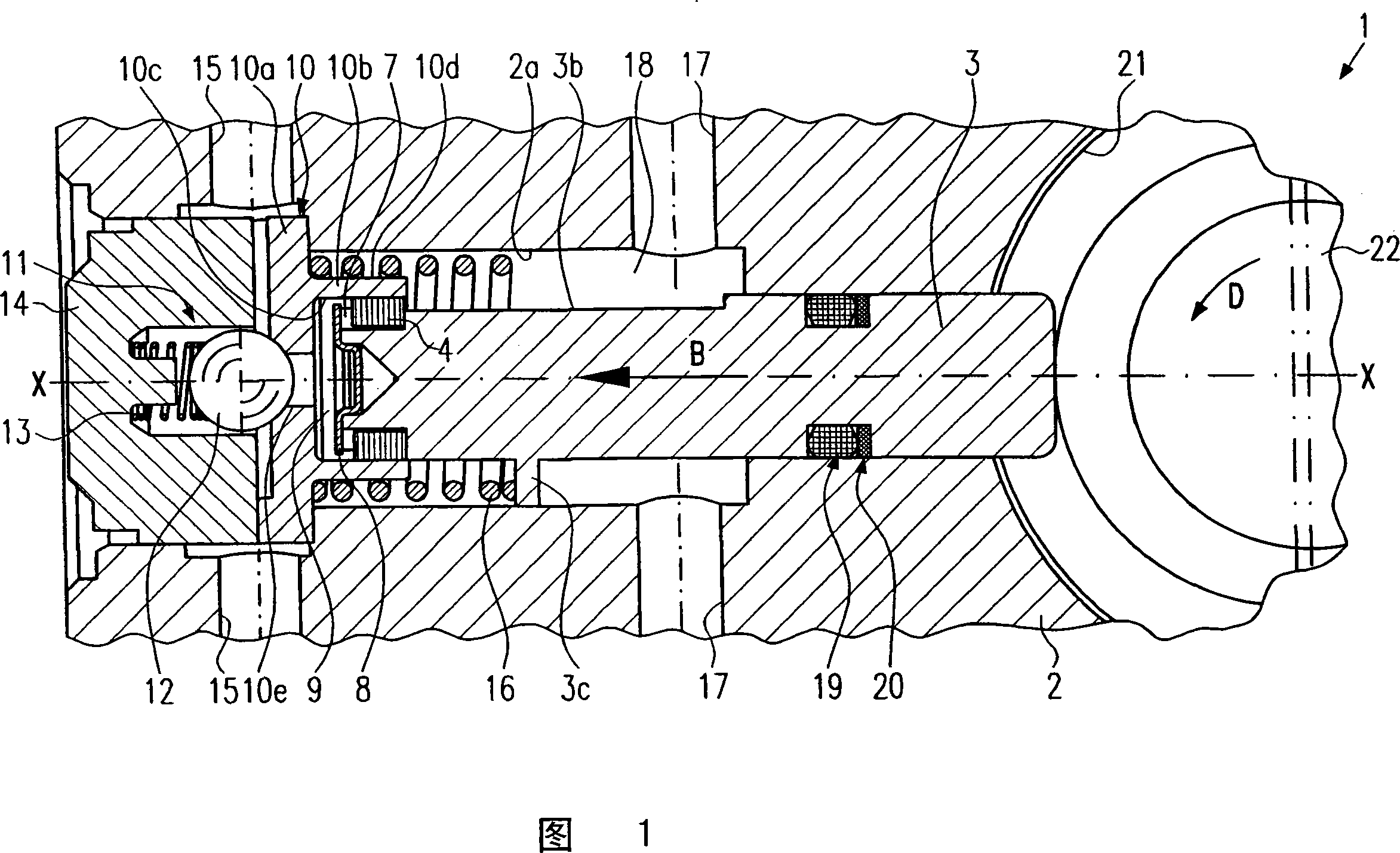

[0024] A piston pump 1 according to a first exemplary embodiment of the invention will be described below with reference to FIGS. 1 to 6 .

[0025] As shown in FIG. 1 , the piston pump 1 comprises a piston 3 which is arranged in a housing 2 . The housing 2 has a stepped hole 2 a for receiving the piston 3 . The piston 3 is driven by means of an eccentric 22 , the direction of rotation of which is indicated by the arrow D, which is arranged in the eccentric chamber 21 .

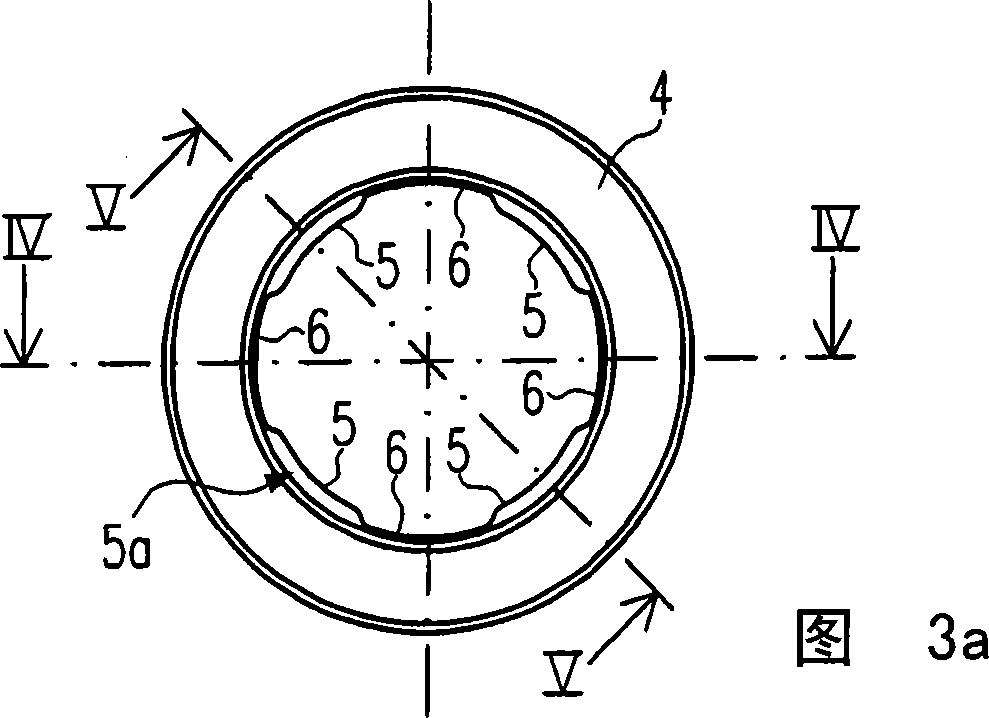

[0026] The piston 3 is shown in detail in the perspective view of FIG. 2 . It can be seen from FIG. 2 that the piston 3 has, at its end on the pressure chamber side, a stepped region 3 a and three flattened regions 3 b arranged along the circumference of the piston. It can be seen in particular from FIGS. 1 , 5 and 6 that a sealing element 4 is arranged on the stepped region 3 a. The sealing element 4 is fixed on the stepped region 3 a of the piston 3 by means of a spring element 7 and a plate-shaped holdin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com