Vehicular automatic transmission

一种自动变速器、车辆的技术,应用在车辆变速箱、车辆部件、传动箱等方向,能够解决不能用于使用车辆等问题,达到减少停工的风险、减小长度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

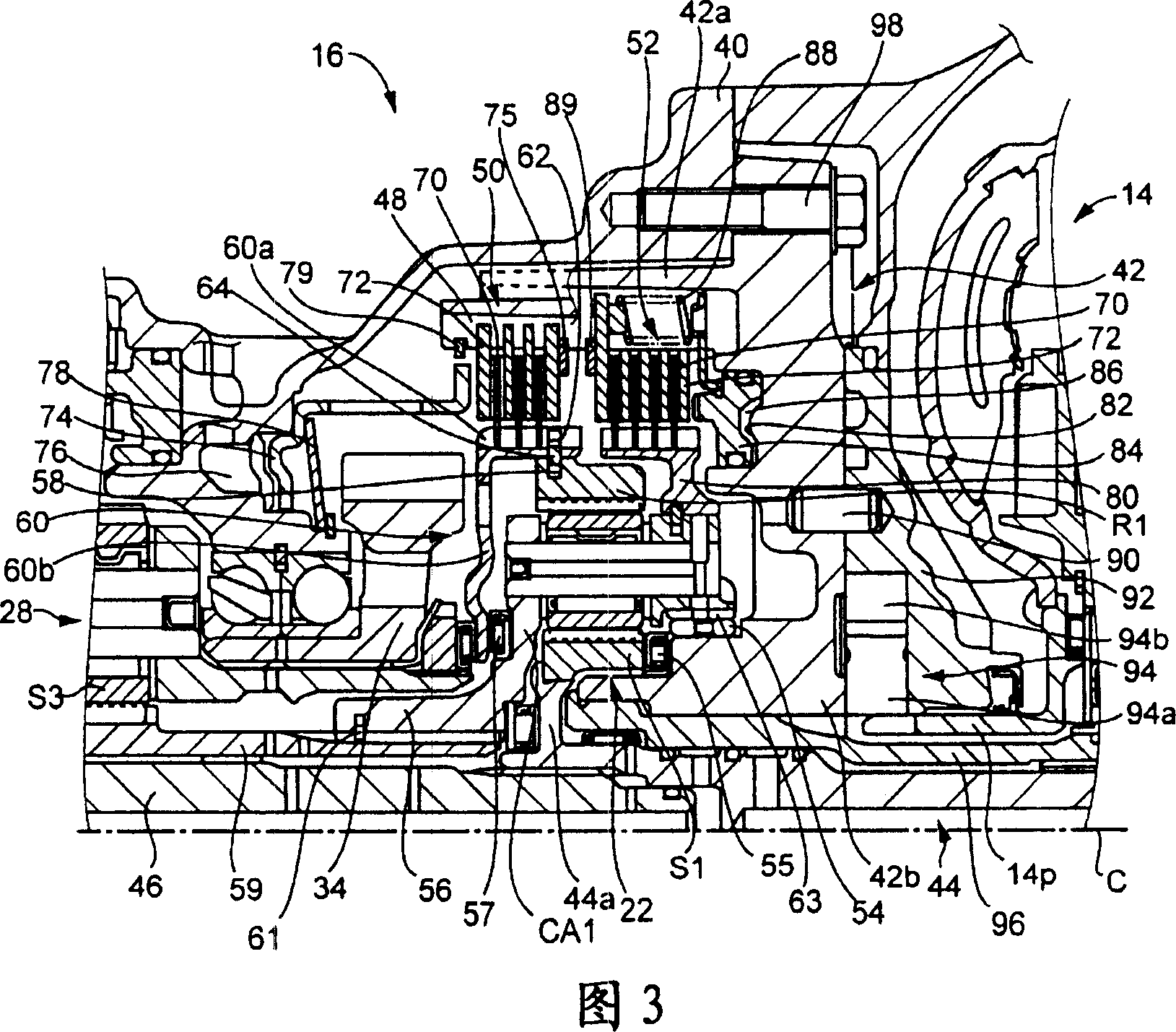

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

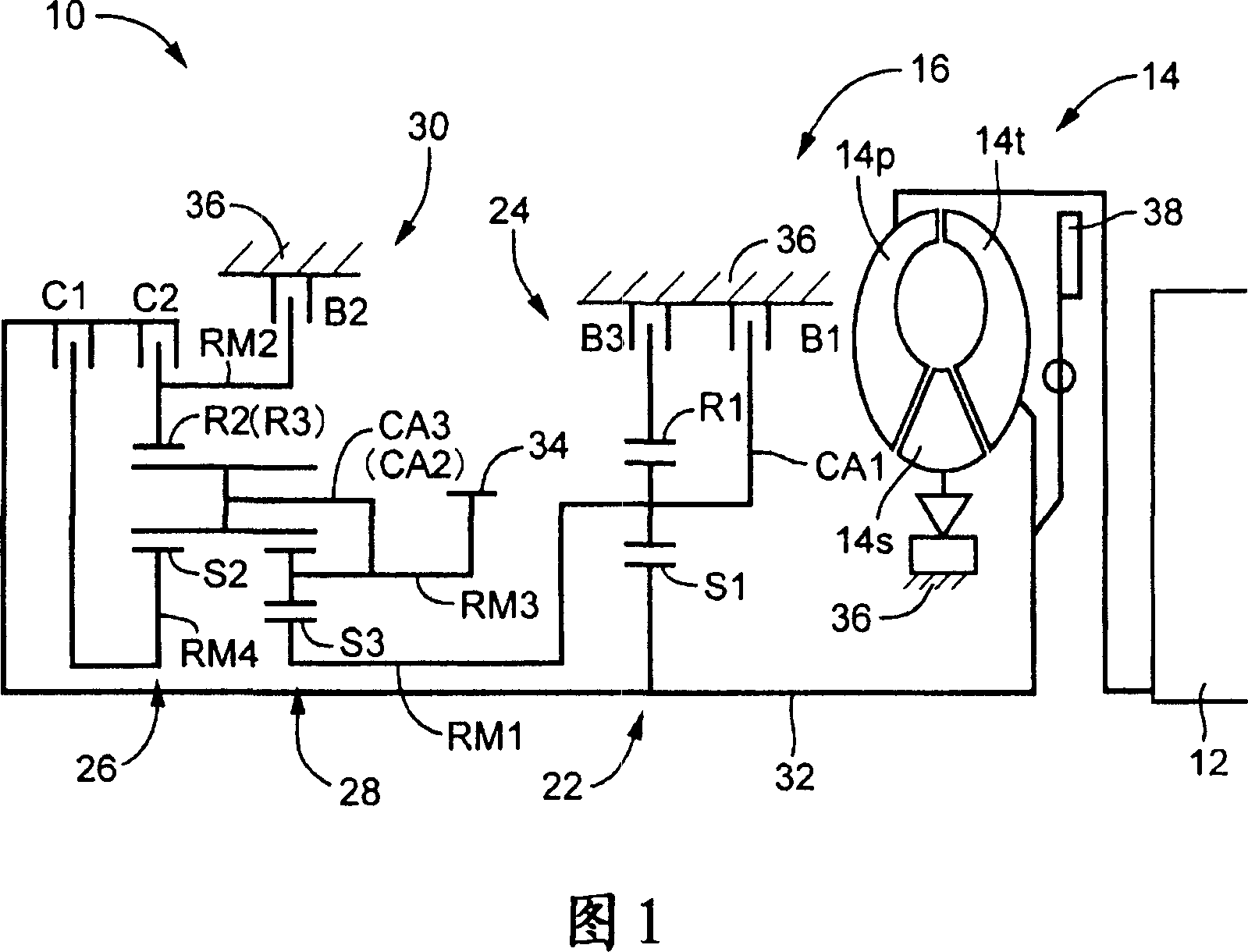

[0022] Referring first to the schematic diagram of FIG. 1 , there is shown a drive system 10 for a vehicle, which is suitable for a FF vehicle (front engine front drive vehicle) and is equipped with a driving force source in the form of an internal combustion engine 12 . The output of the internal combustion engine 12 is transmitted to the left and right sides of the vehicle through a fluid-operated power transmission in the form of a torque converter 14, an automatic transmission 16, a differential gear arrangement (not shown), and a pair of axles (not shown). drive wheel. The automatic transmission 16 is an automatic transmission for a vehicle constructed according to a preferred embodiment of the present invention.

[0023]The torque converter 14 includes a pump impeller 14p connected to the crankshaft of the internal combustion engine 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com