Ink-jet printer cartridge and pressure balancing unit thereof

A technology of inkjet printers and balancing devices, which is applied in printing and other directions, and can solve the problems of reducing the effect of ink cartridges on the machine and not being easy to eliminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

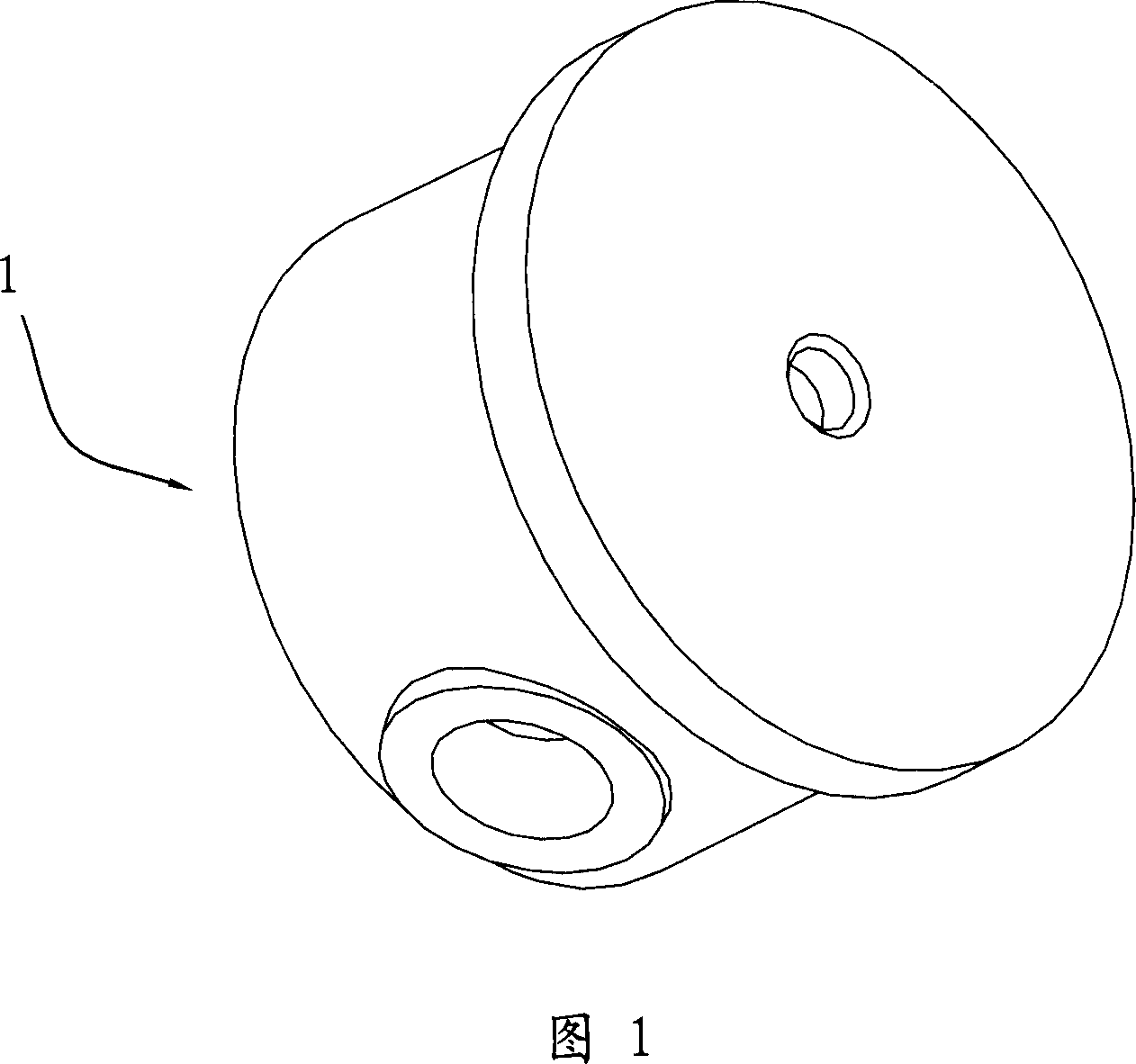

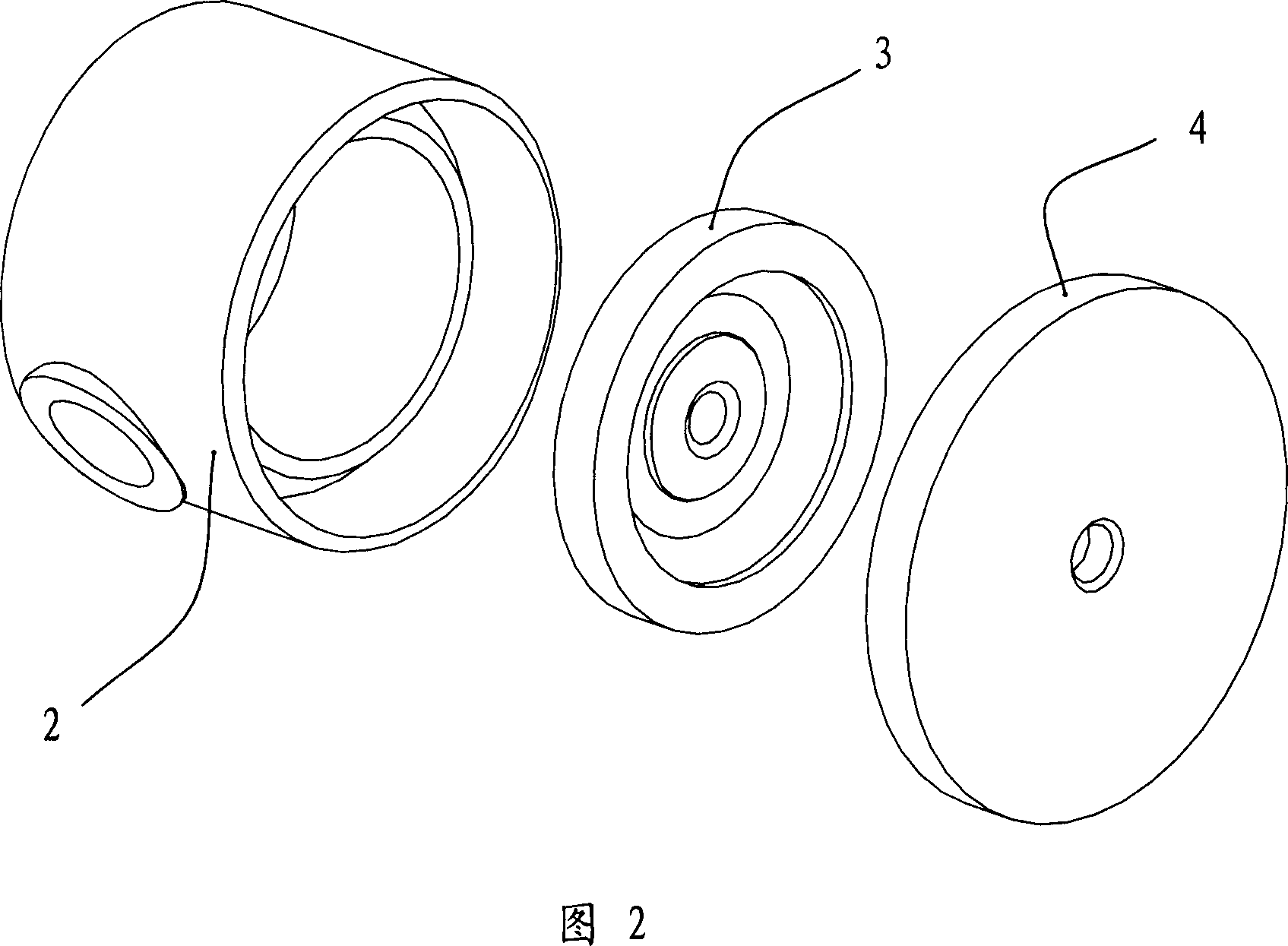

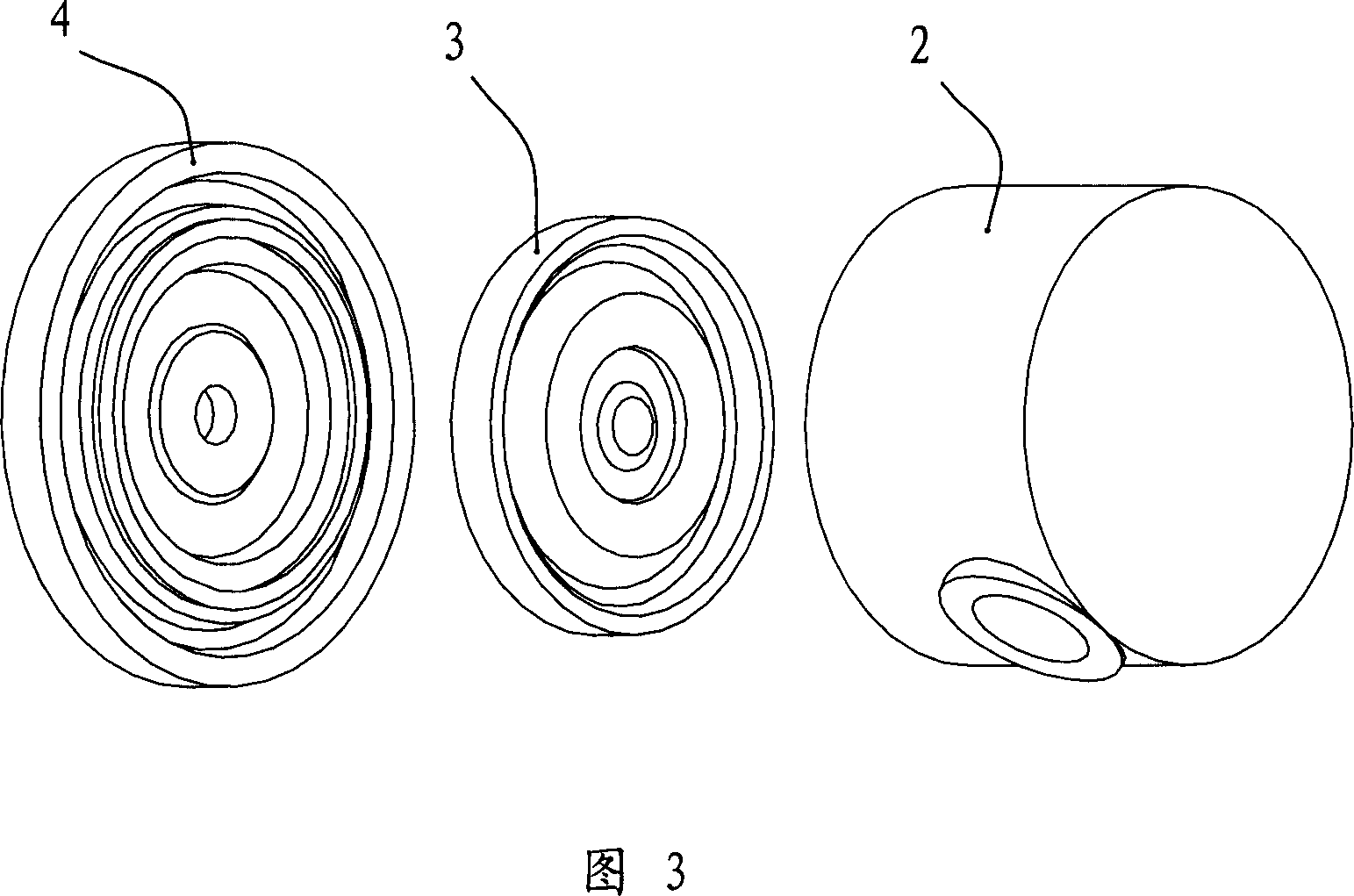

[0030] Referring to Figures 1, 2, 3 and 7, the pressure balance device 1 for an inkjet printer cartridge of the present invention mainly includes a cover 4, a diaphragm 3 and a seat 2. The cover body 4 is tightly sealed on the seat body 2 to form a closed inner cavity. The membrane 3 is arranged in this interior. The inner cavity of the pressure balance device 1 is divided into a first chamber a and a second chamber b which are isolated from each other with the diaphragm 3 as a boundary. The pressure balance device 1 can be arranged on the side wall or inner wall of the ink cartridge above the ink supply port of the inkjet printer ink cartridge (see FIG. 10 ). The second chamber b between the diaphragm 3 and the cover body 4 passes through the balance through hole 43 (see Figure 4) that is offered on the cover body 4, so that the side of the diaphragm 3 facing the second chamber b is always in contact with the outside atmosphere or The inks in the ink storage chambers of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com