Flat-panel display apparatus

A display device, flat-type technology, applied in identification devices, cooling/ventilation/heating renovation, instruments, etc., can solve problems such as reduced adhesion and reduced thermal conductivity, and achieves the effect of superior cost characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

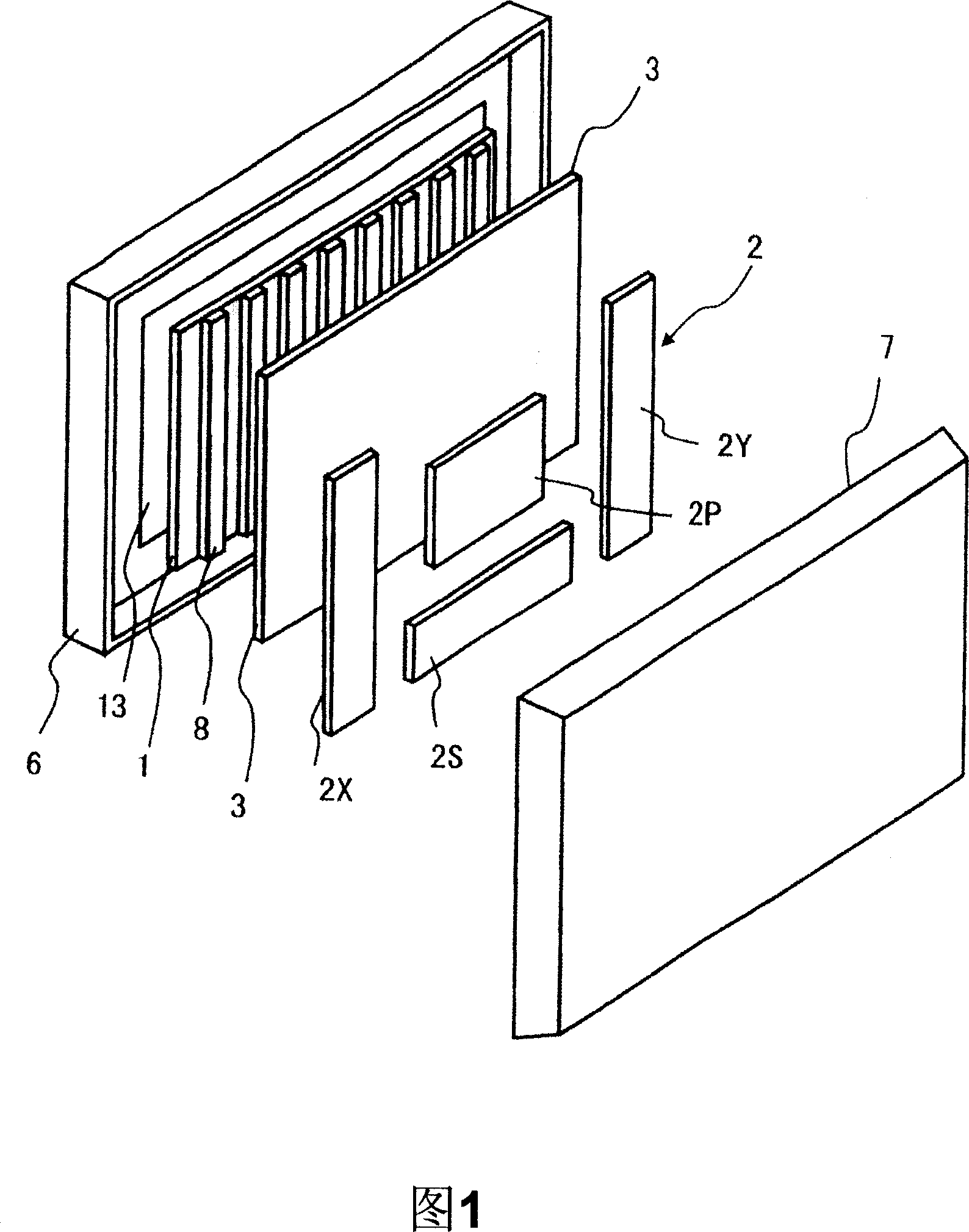

[0040] FIG. 1 is an exploded perspective view showing the configuration of main parts of a plasma display device according to Embodiment 1 of the present invention.

[0041]In FIG. 1 , the housing for accommodating the PDP 1 is composed of a front frame 6 in which a front cover 13 made of glass or the like is disposed in an opening, and a metal rear cover 7 . For example, the PDP 1 is bonded to the front surface of the chassis member 3 made of aluminum or the like via the thermally conductive member 8, the PDP 1 is held, and a plurality of circuit boards 2 for display driving the PDP 1 are mounted on the rear side of the chassis member 3. The thermally conductive member 8 can efficiently transfer the heat generated in the PDP 1 to the chassis member 3 to dissipate heat. The chassis member 3 functions as a holding member for holding the above-mentioned PDP 1 to dissipate heat generated from the PDP 1 to cool the PDP 1 . In addition, the circuit board 2 includes an X sustaining...

Embodiment 2

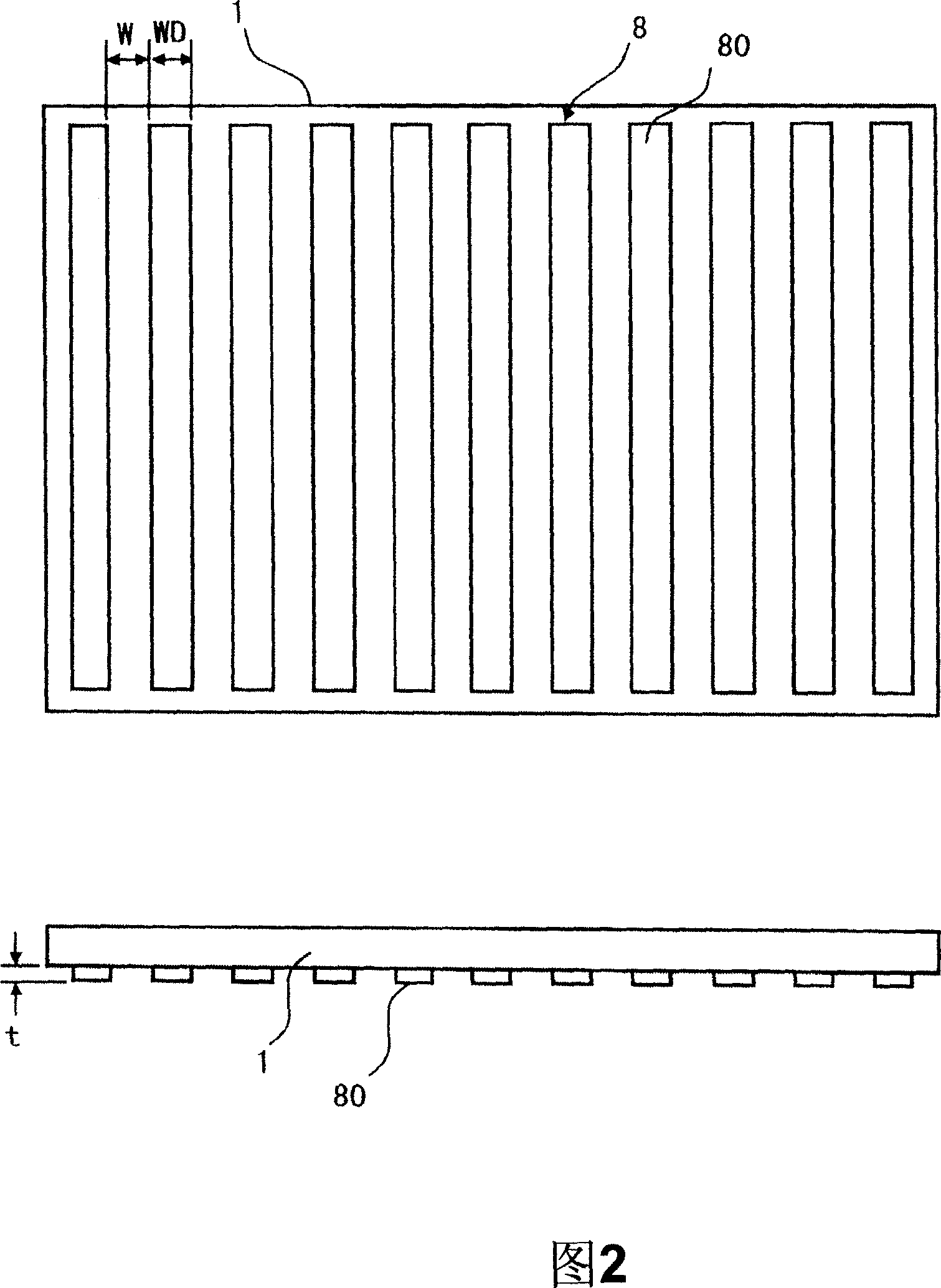

[0076] In Example 1, the thermally conductive member (HM adhesive) was applied in a rectangular shape with a predetermined width at predetermined intervals along the longitudinal direction of the PDP (horizontal direction of the screen), but the present invention is not limited thereto.

[0077] 7 is a schematic view of the thermally conductive member coated on the back side of the PDP of Example 2 viewed from the thermally conductive member side.

[0078] In FIG. 7, the thermally conductive member 8 is applied in a strip-shaped rectangular shape parallel to the short side of the PDP (vertical direction of the screen) at predetermined intervals W along the long side direction of the PDP (horizontal direction of the screen) (hereinafter, called "rectangular shape"). However, in this example, unlike Example 1, the luminance is dispersed at a predetermined interval WV (for example, WV=10mm or less when the coating thickness is 0.5mm) that does not cause brightness unevenness in t...

Embodiment 3

[0081] Embodiment 3 of the present invention will be described below. 8 is a schematic view of the thermally conductive member coated on the back side of the PDP of Example 3 viewed from the thermally conductive member side.

[0082] In Example 1, the thermally conductive member (HM adhesive) was applied in a rectangular shape with a predetermined width at predetermined intervals along the longitudinal direction of the PDP (horizontal direction of the screen), but in this embodiment, as shown in FIG. As shown, the width WD of the rectangular thermally conductive portion 82 is made larger on the screen center side and smaller on the screen edge side.

[0083] As described above, when a person looks at a screen, the viewpoint usually coincides with the center of the screen, so it is necessary to take care not to cause brightness unevenness in the center of the screen. Therefore, by increasing the width WD of the rectangular heat conduction portion 82 in the central portion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com