Three dimension arch steel concrete structure formwork and construction method

A technology of reinforced concrete and construction method, which is applied in the direction of formwork/formwork/work frame, building components, building structure, etc., can solve the problems of high cost, fast erection speed, poor construction effect, etc., and achieves simple formwork dismantling. , The effect of good molding effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

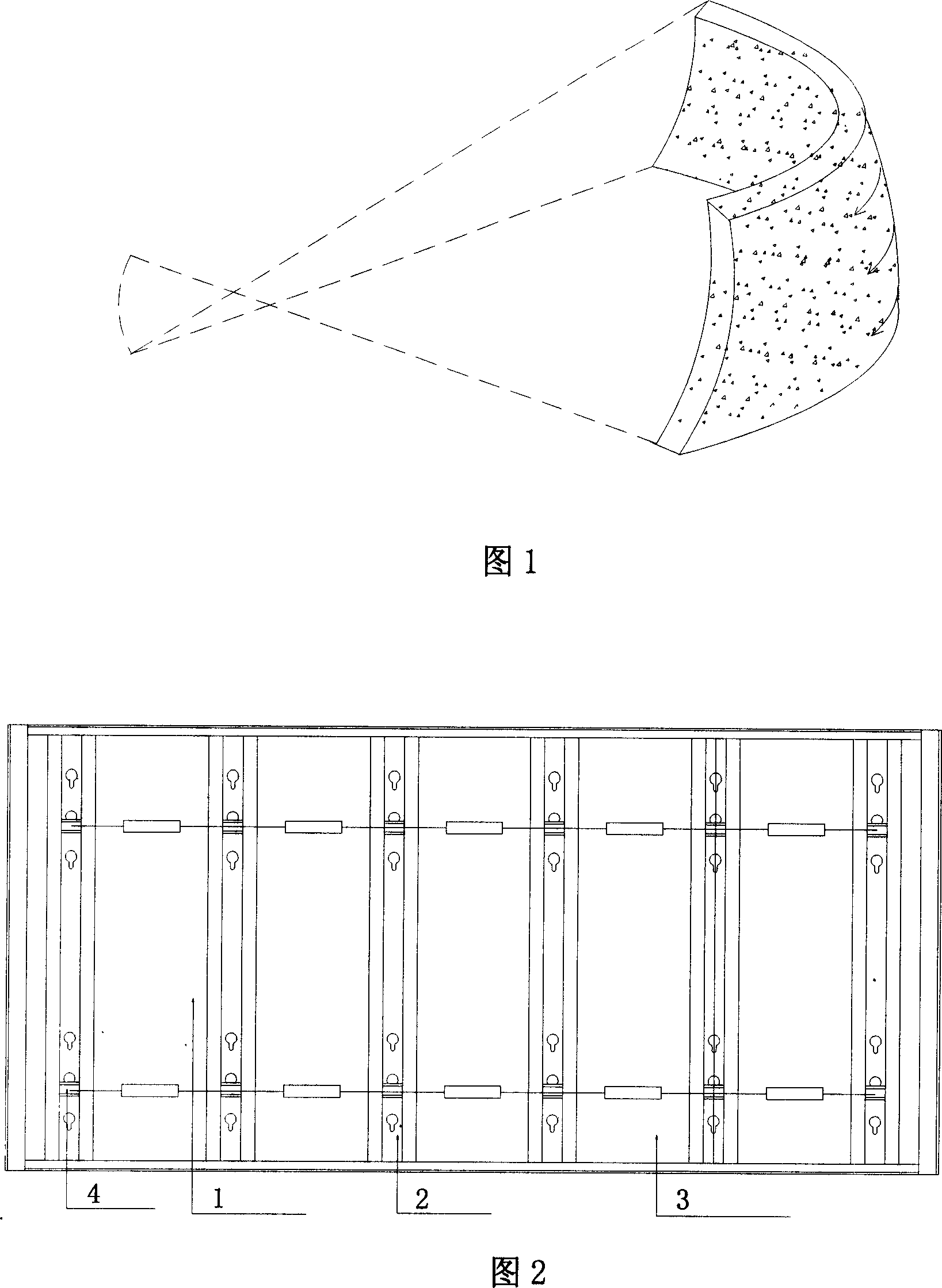

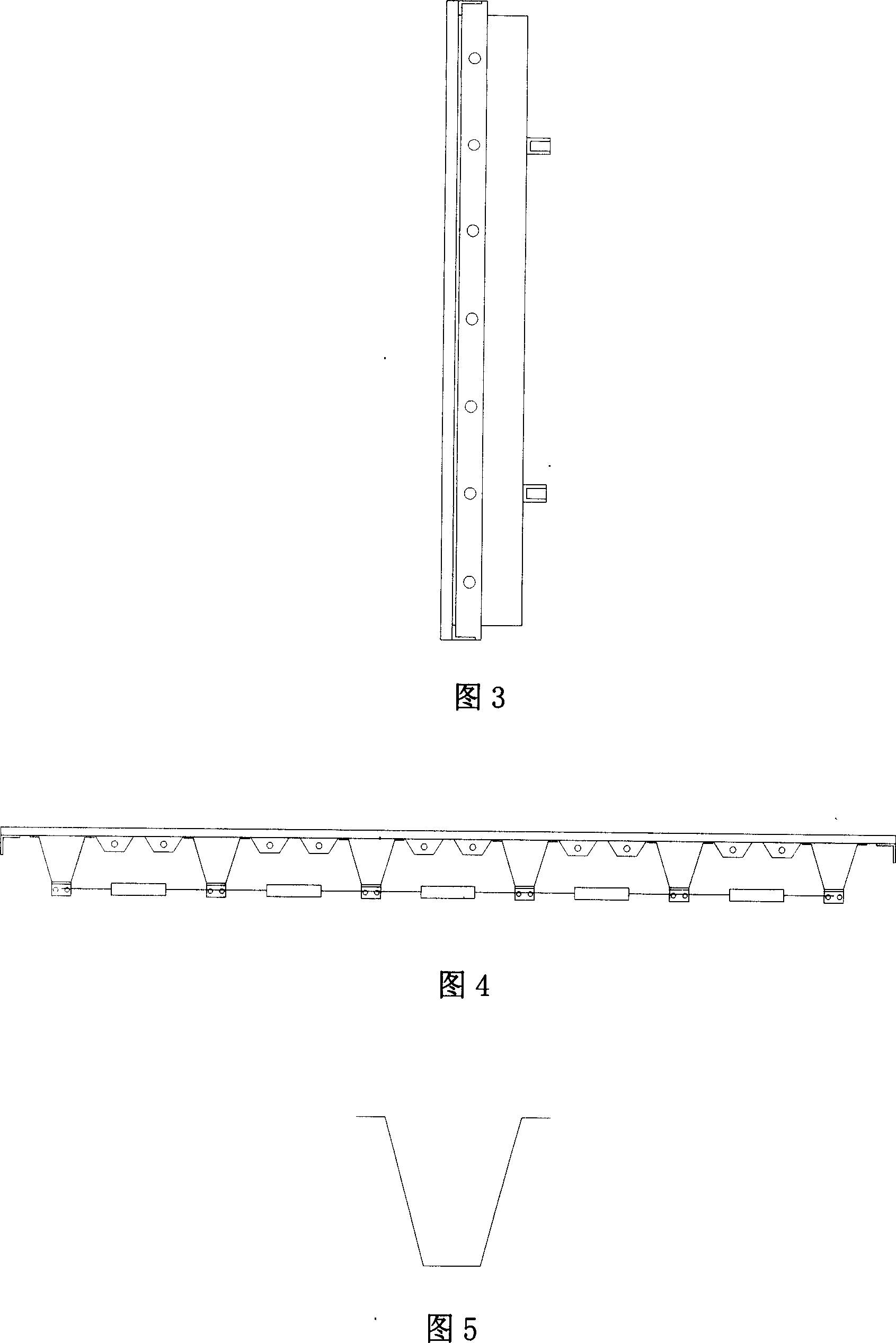

[0047] Taking the wall as a three-dimensional curved wall as an example, the elevation is +0.5~+5.5; +5.5~+9.7, to the parapet wall, there are wall 1, wall 2, wall 3, wall 4, wall 5, wall 9, and the wall thickness is 300-400mm, three-dimensional curved walls with different heights and different radii. This is a major feature of the project's artistic requirements, and it is also the biggest difficulty of the concrete formwork.

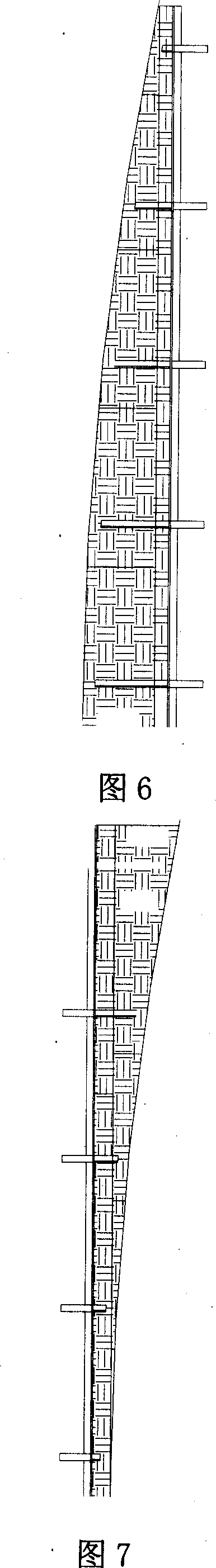

[0048] In view of the above characteristics, it was decided to use the technology of "wall reinforced plywood large formwork" for combined design, equipped with related components and support control system, to solve the changes of different curvatures in three-dimensional space, to ensure simple dismantling of formwork, high work efficiency, and can be used in different The height of the floor can be casted to meet the requirements of the clear water surface wall. There are 12 three-dimensional walls in this project, and the formwork makes a total of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com