Pneumatic tire

A technology for pneumatic tires and treads, applied to the reinforcement layer of pneumatic tires, tire parts, wheels, etc., can solve the problems of quietness and poor ride comfort, and achieve reinforcement unevenness, small road noise, and good ride comfort sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

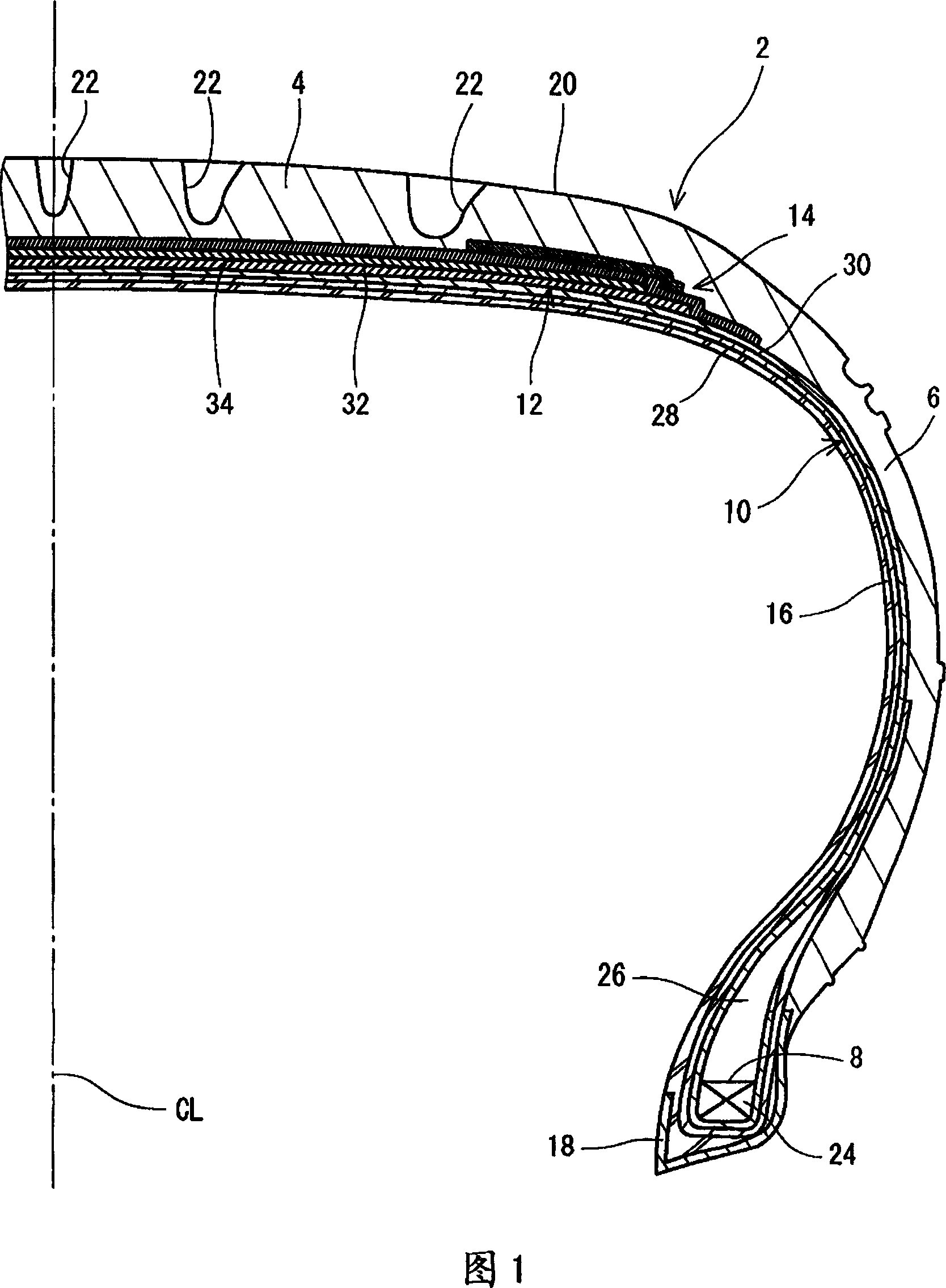

[0056]Pneumatic tires for passenger vehicles having the structures shown in FIGS. 1 to 3 were obtained. Details of the tire cap are shown in Table 1 below. In a tire, the angle formed by the belt cords of the inner belt ply relative to the equatorial plane is +24 degrees and the angle formed by the belt cords of the outer belt ply relative to the equatorial plane is -24 degrees Spend. The tire size is "205 / 50R17". The axial distance WA between the outer end of the full crown belt and the outer end of the belt is 5 mm. The distance WB between the outer end of the belt and the outer end of the edge cap was 3 mm. The axial distance WC between the outer end of the full crown belt and the outer end of the belt is 8mm. The ratio of the axial distance WD between the outer end of the full cap and the inner end of the marginal cap to the width WS of the full cap (WD / WS×100) was 17.6%.

Embodiment 6 to 9

[0058] A tire was obtained in the same manner as in Example 1 except that the axial distance WA was set as shown in Table 1 below.

Embodiment 10 and 11

[0060] Tires were obtained in the same manner as in Example 1 except that the axial distance WB was set as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com