Steam cleaner

A cleaning machine and steam technology, applied in the field of steam cleaning machines, can solve the problems of inconvenient cleaning, low service life, poor spray efficiency, etc., and achieve the effects of convenient cleaning, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

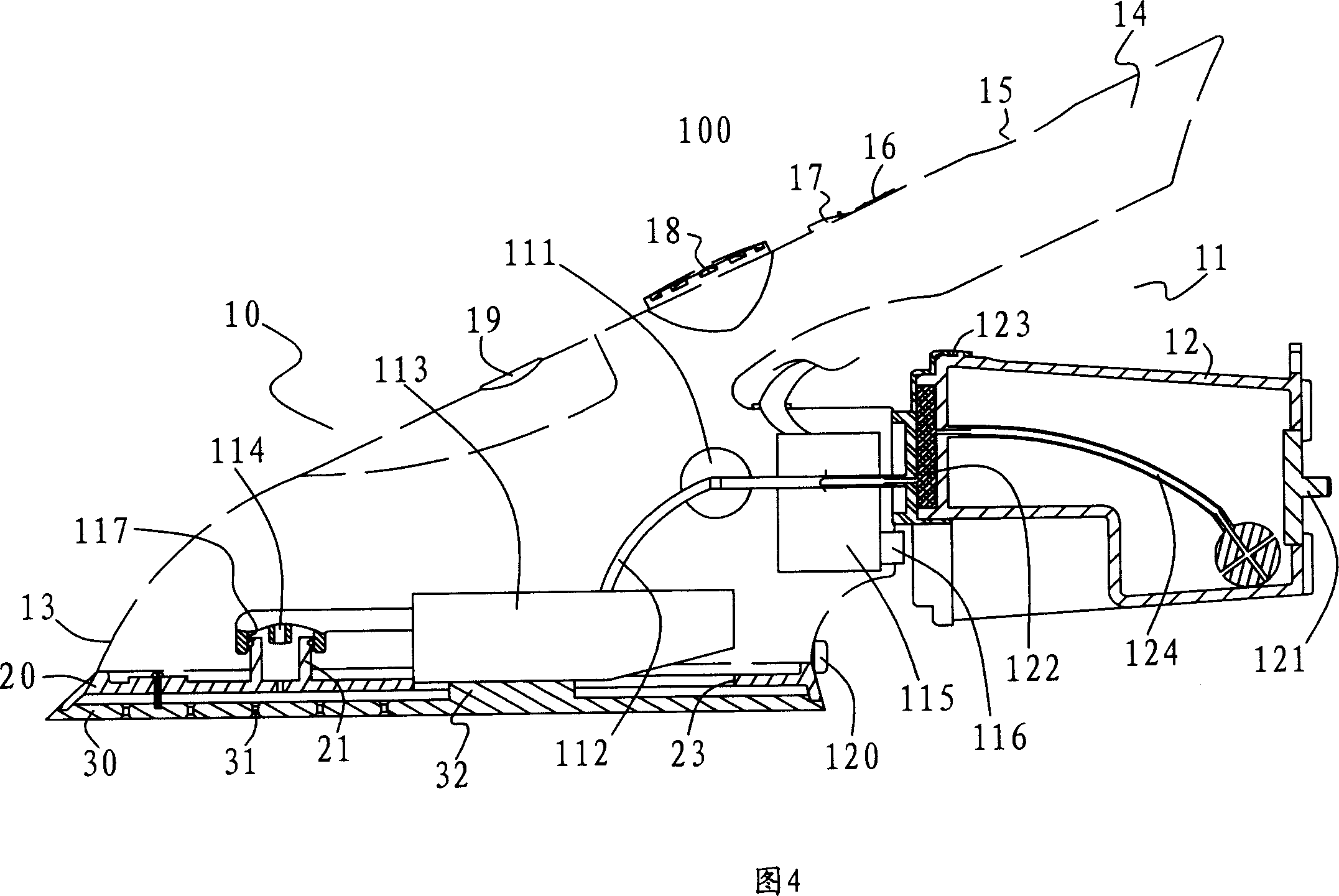

[0071] The present invention will be described in detail below with reference to the drawings.

[0072] FIG. 1 is an assembly perspective view of a preferred embodiment of the present invention. Except for the storage barrel 12, the other components and pipelines of the entire water supply system are installed in the housing 13 to form a main body 10.

[0073] The end of the main body 10 is connected to the storage barrel 12, and a hollow handle 14 extends obliquely above. The handle 14 has a button hole 15, a constant pressure block 16, a button 17, a knob 18, and a lamp 19, among which:

[0074] The button hole 15 is for inserting and engaging long rods (not shown) to extend the height of use;

[0075] The constant pressure block 16 is an auxiliary component of the button 17. It can be seen from Figures 2 and 3 that when the constant pressure block 16 stops at the original position, force is applied to the button 17 to press it down, and once it is released, it can return to its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com