Variable function toothbrushes

A toothbrush, variable technology, applied in the direction of dentistry, brushes, brush body, etc., can solve the problem of not allowing the brush head to rotate for control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

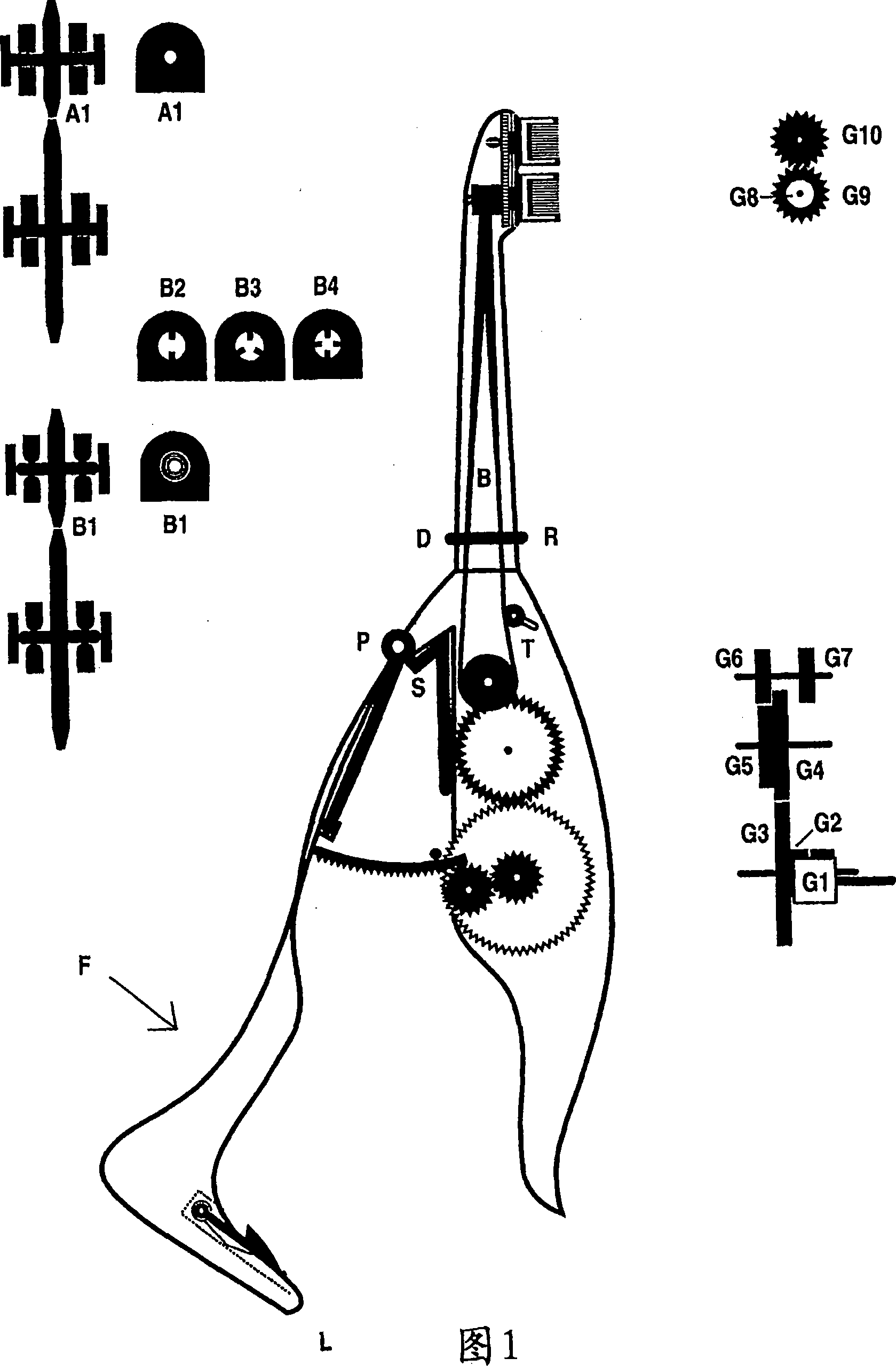

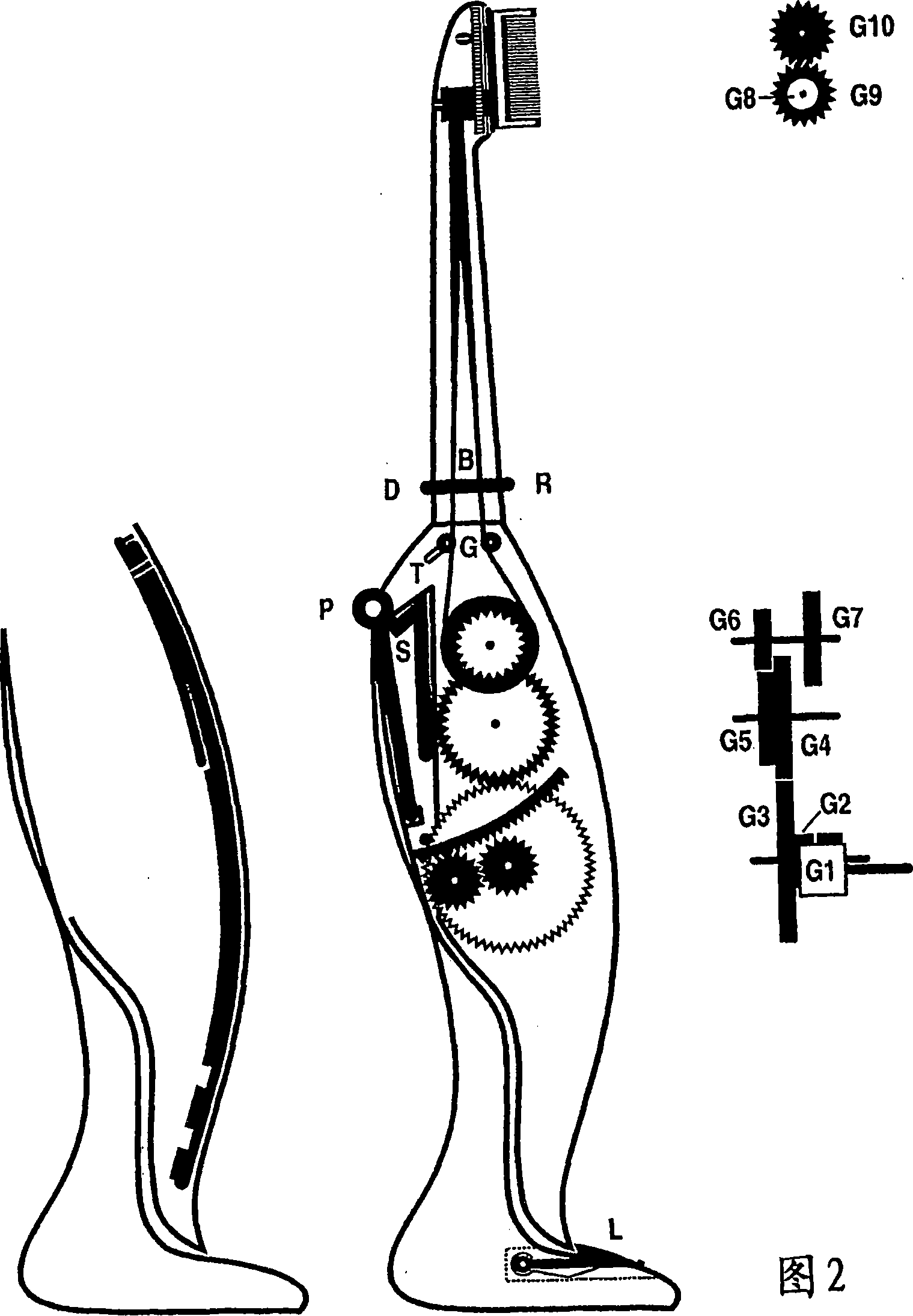

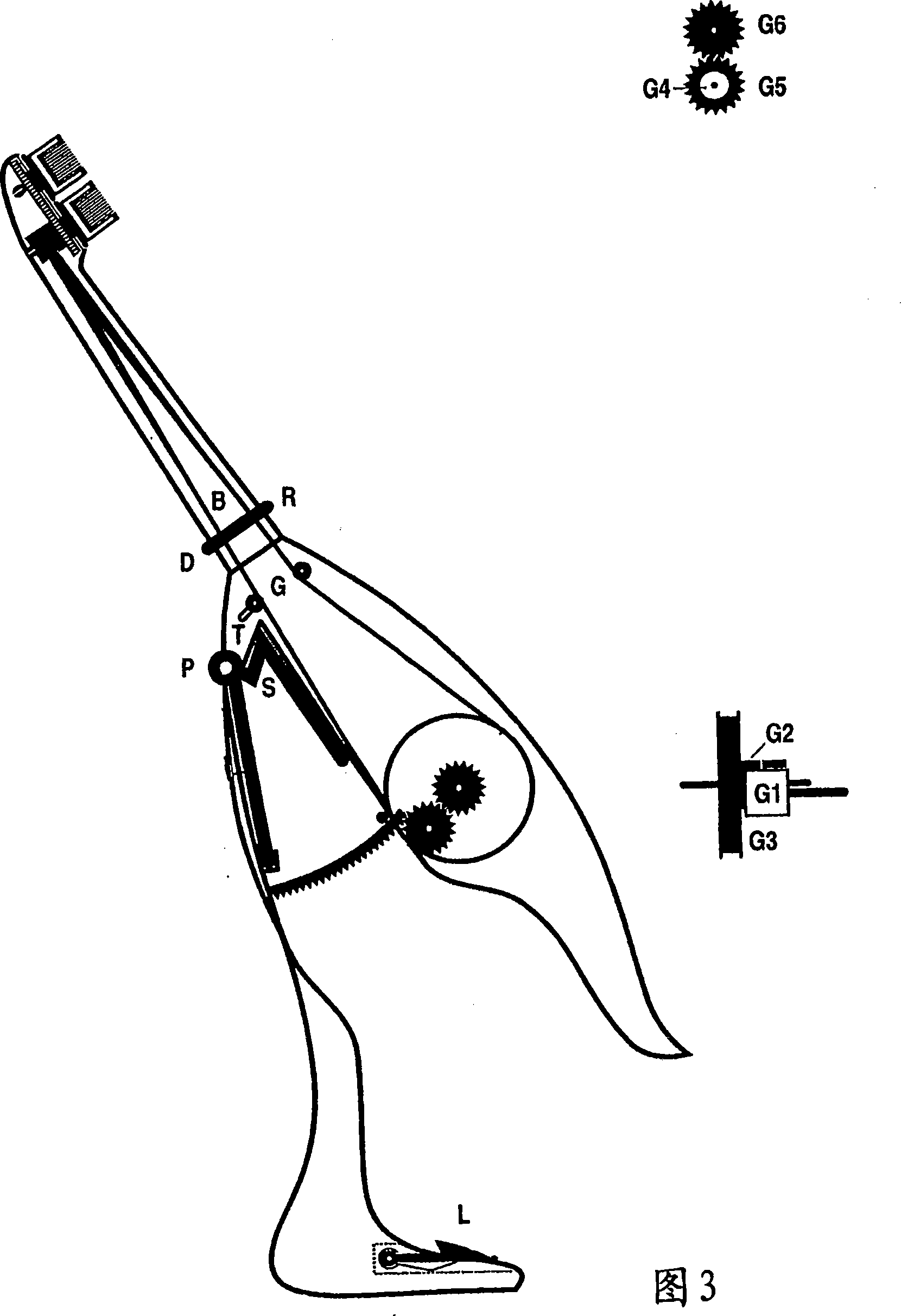

[0028] Referring first to Figure 1 of the drawings, there is shown a hand operated toothbrush with a toothed drive belt in an unactuated mode and two brush units, the brush body and head can be separated and actuated and used in the following manner;

[0029] In FIG. 1 , the brush body shows a transmission actuated by a force F on a lever with a spring S at its pivot P. When this lever is actuated, the toothed drive belt B connecting the transmission in the brush body and the brush head rotates the brush unit multiple times through 360°. These brush units rotate in different directions, thereby eliminating any skating rotation. When the force is released from the lever, the compressive energy in the spring causes the lever to return to its original position and, in the process, counter-rotate the brush unit, drive belt and transmission within the brush body.

[0030] The transmission shown in Figure 1 allows the brush unit to rotate and counter-rotate multiple times each time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com