Parts supply device

A supply device and component technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve problems such as widening, inability to ensure positional accuracy, and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

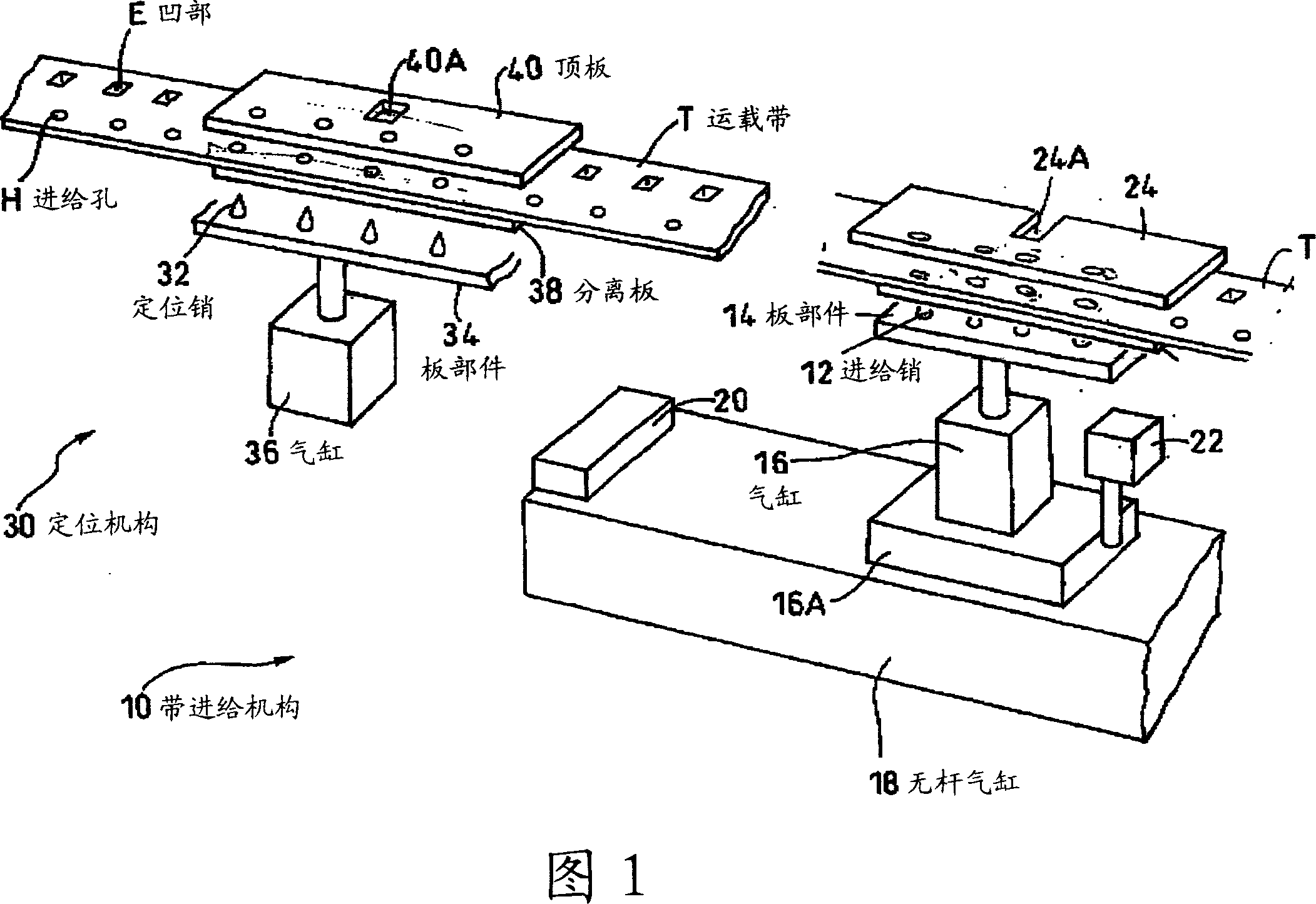

[0034] FIG. 1 shows an outline of a tape feed mechanism and a tape positioning mechanism included in a components supply device according to an embodiment of the present invention. This component supply device is used by being attached to a component mounting device not shown, and is a so-called tape feeder.

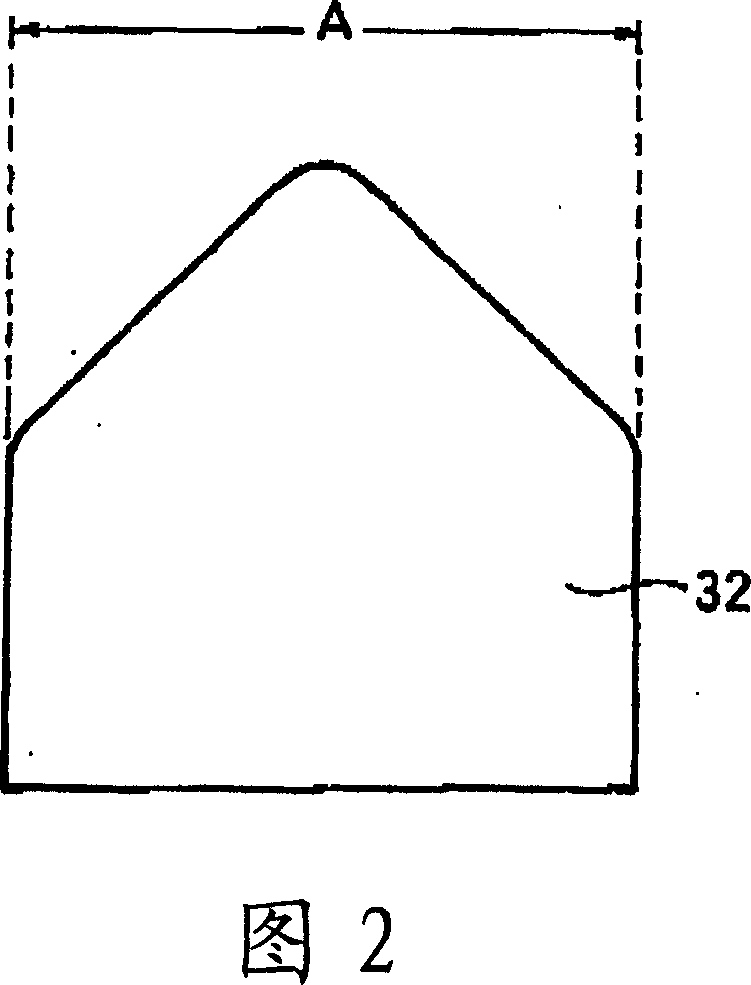

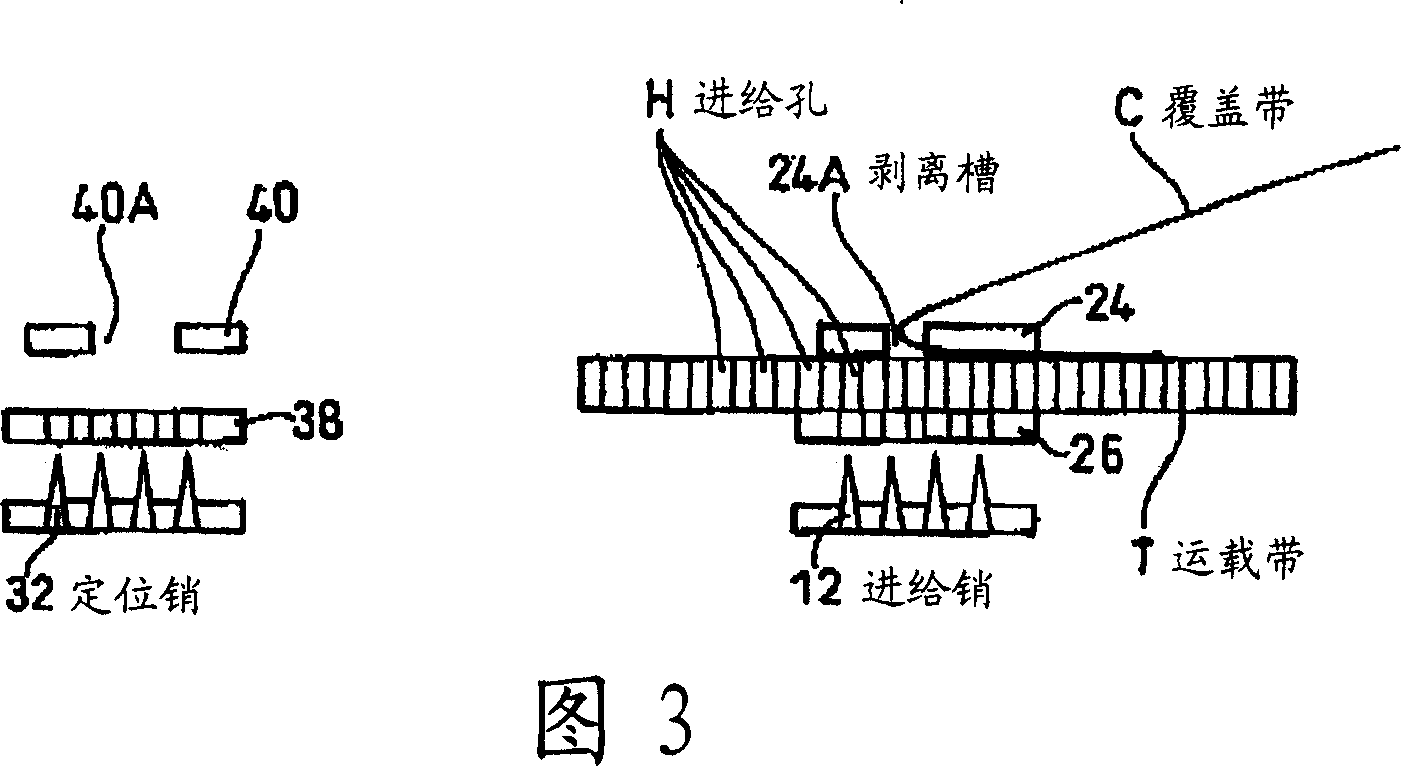

[0035] The tape feeding mechanism 10 of the present embodiment is arranged along the conveying path, and is a tape feeding mechanism of the type that pinches the carrier tape T unwound and supplied from a roll not shown in the upper and lower sides. A mechanism that raises the feed pin 12 is attached after the carrier tape T is sandwiched between both in either state. Furthermore, the tape feed mechanism 10 includes: a plate member 14 on which a plurality of (four in the figure) feed pins 12 are erected at the same pitch as the feed holes H of the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com