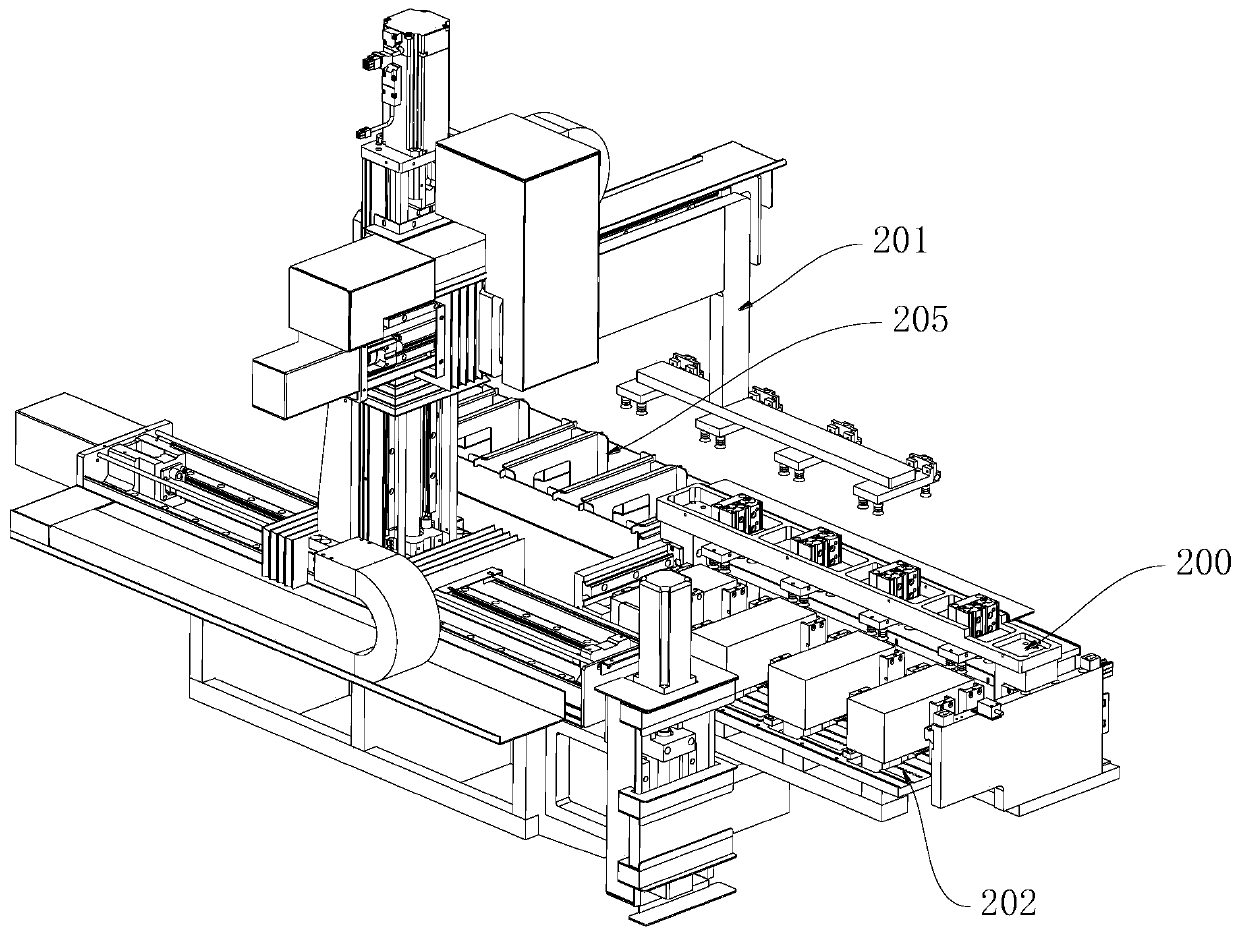

Laminated glass sheet separating and taking-out mechanism and method and glass sheet conveying equipment

A glass and lamination technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as easy failure, reduced production efficiency, waste of raw materials, etc., to avoid processing errors, meet production needs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

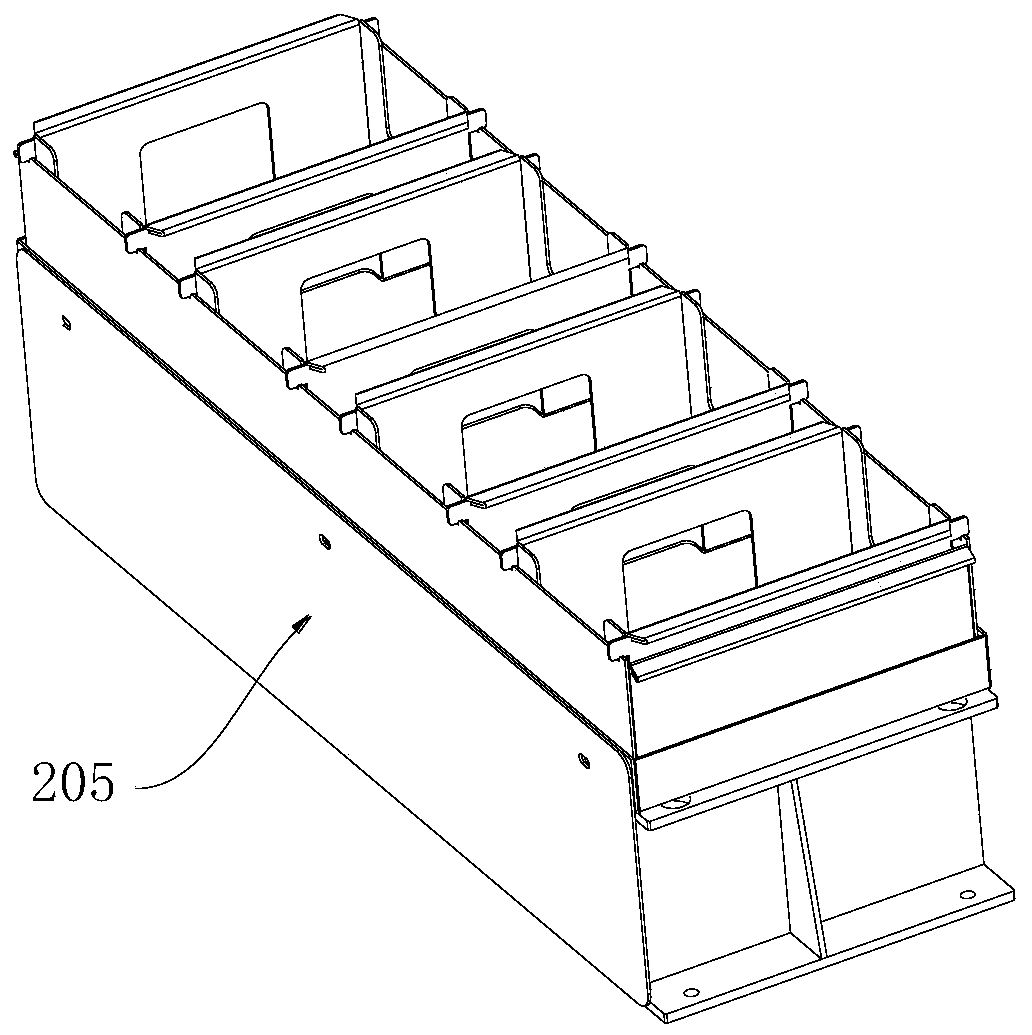

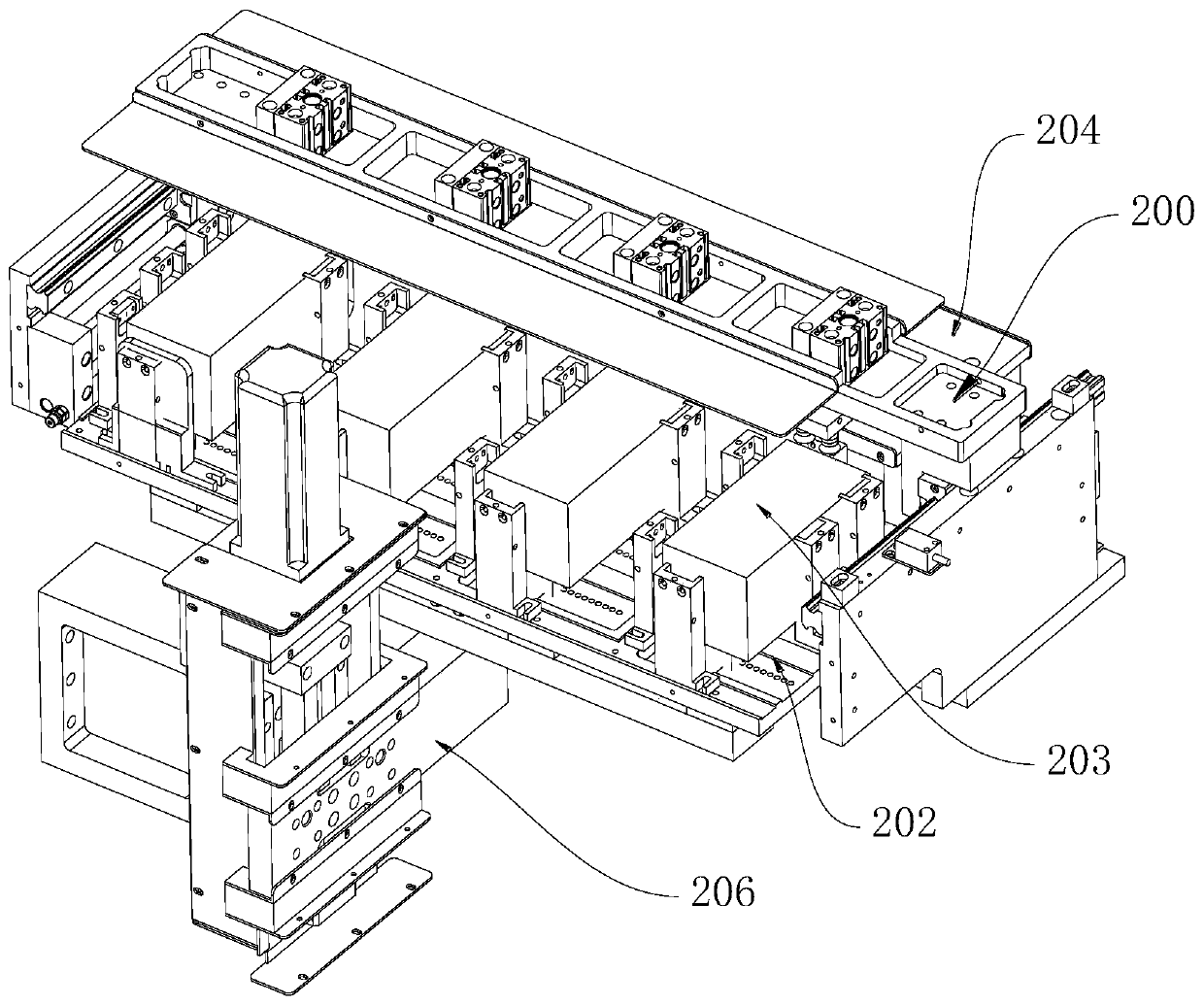

[0032] The invention discloses a laminated glass slice taking-out mechanism, which combines Figure 5 to Figure 10 As shown, it includes a platform 10, the platform 10 is provided with a pick-up plate 11, and the pick-up plate 11 can slide back and forth relative to the platform 10, and the platform 10 is fixed with a The raw material box 12 of the original sheet 100, the raw material box 12 is located on the top of the taking plate 11, and the multi-layer glass original sheet 100 is carried on the top of the taking plate 11, the raw material box 12 includes a The outlet clamping plate 13 on the side, a gap 130 is formed between the outlet clamping plate 13 and the picking plate 11 for a piece of glass original sheet 100 to pass through, and the top of the picking plate 11 is formed with a bearing portion 111 and an adsorption part 110 capable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com