Processing technology for high-resolution digital interface

A digital interface, high-definition technology, applied in the field of high-definition digital interface processing technology, can solve the problems of poor high-frequency characteristics, messy arrangement of core wires, low operating efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

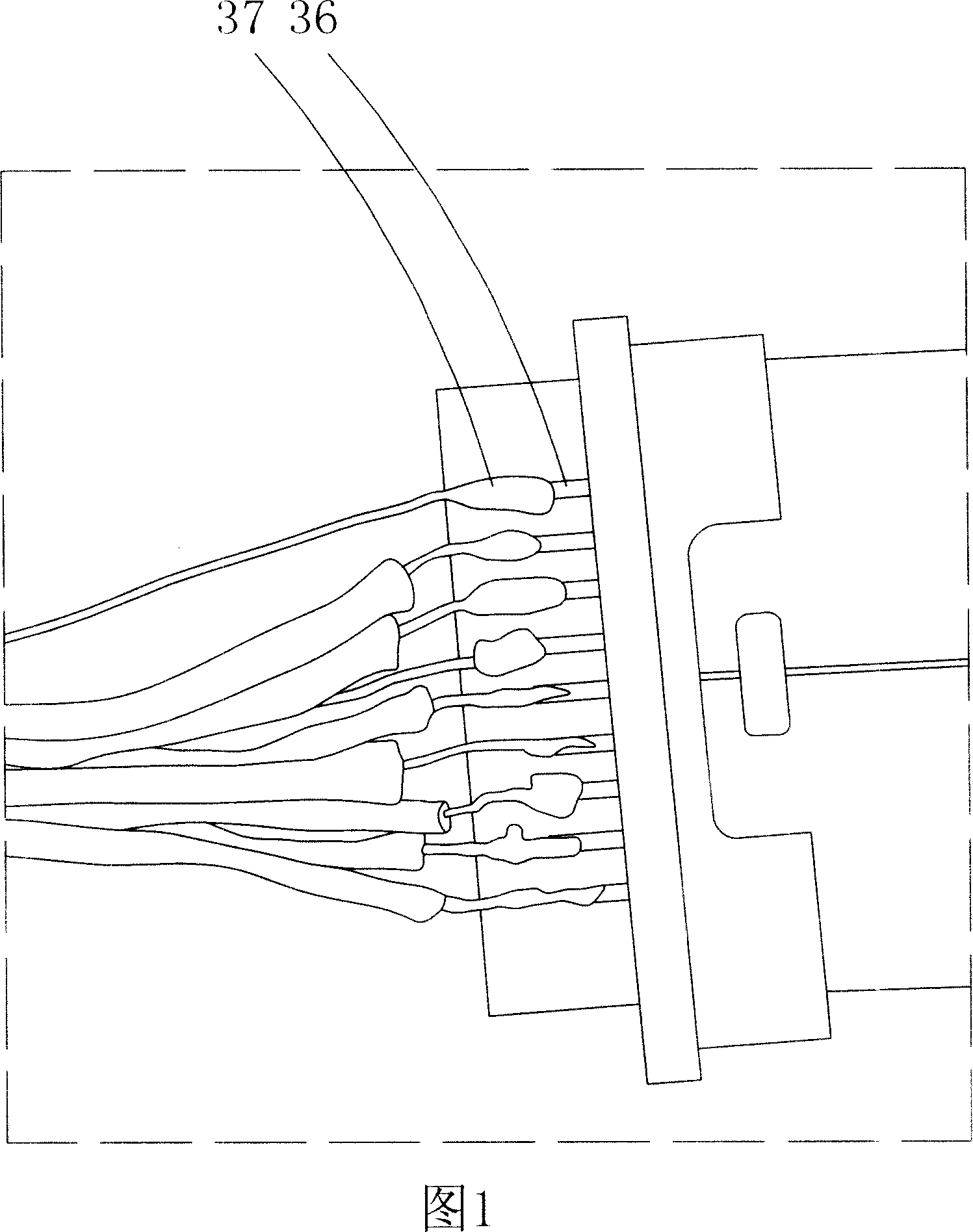

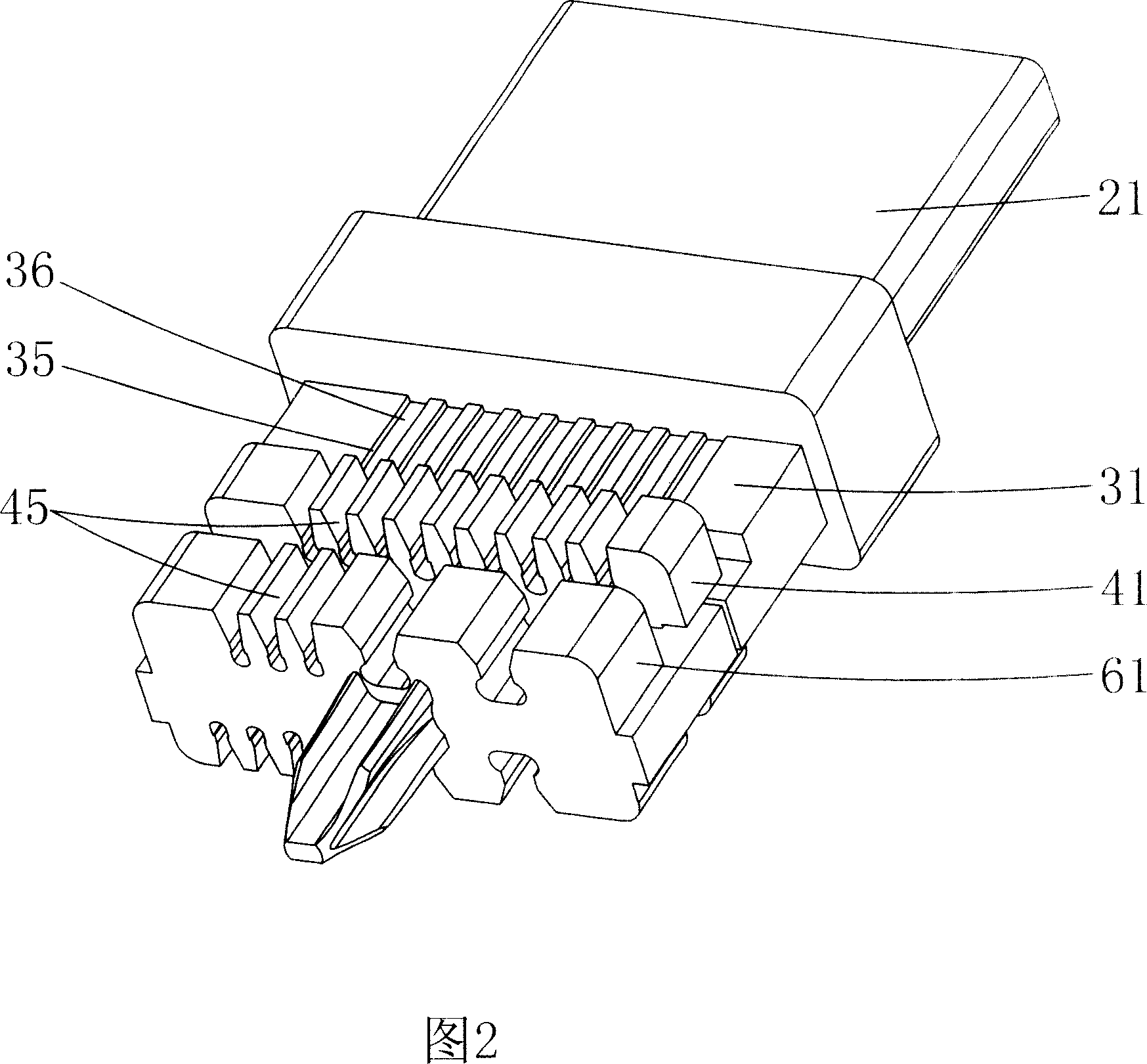

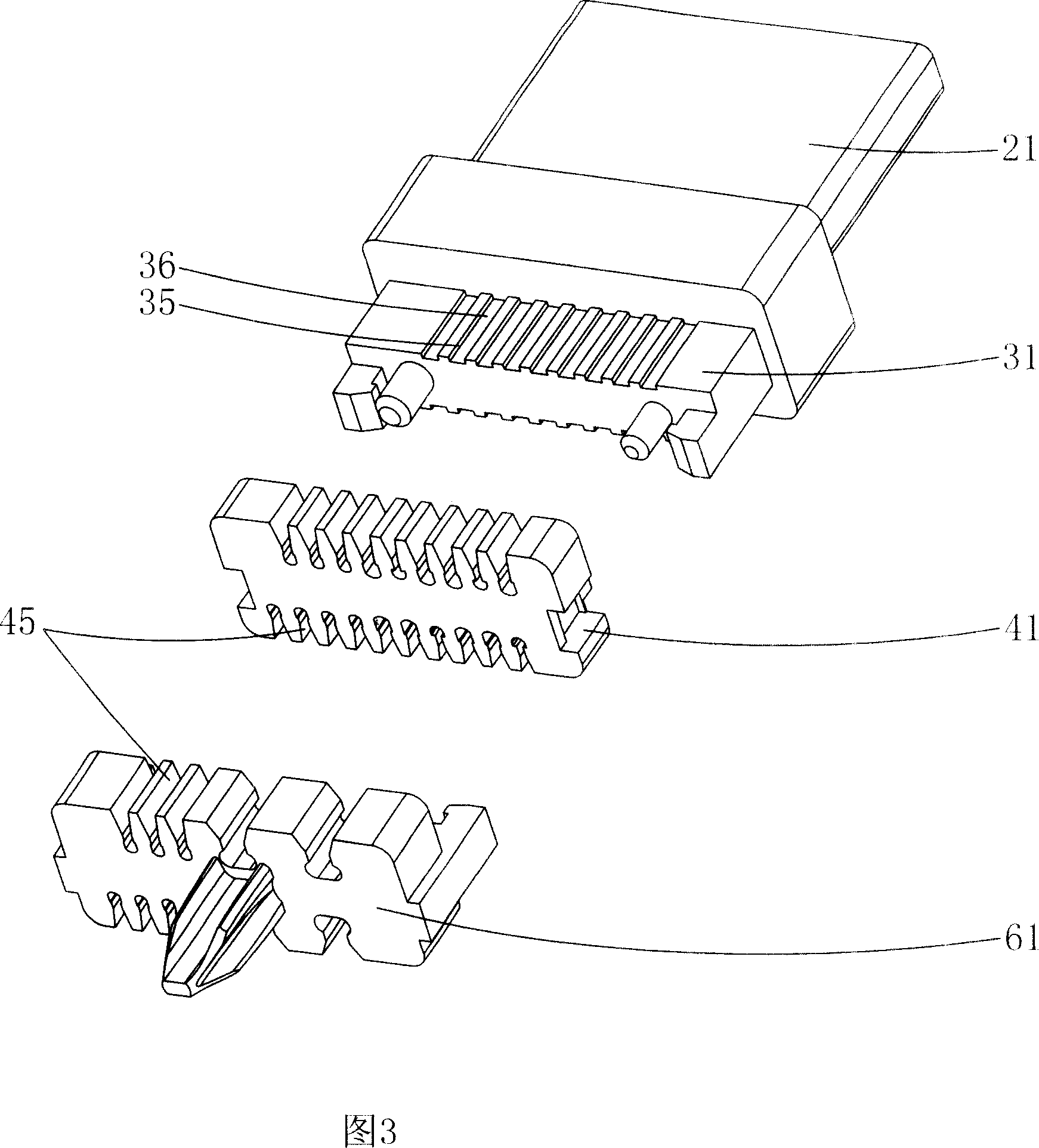

[0022] In order to further prompt the present invention, the processing technology of the present invention will be specifically described below in conjunction with specific embodiments and accompanying drawings 2 and 3 .

[0023] In the present invention, the outermost skin of the wire is first removed, then the dense mesh wire covering the core wire is stripped off, and then the aluminum foil and the inner aluminum foil are removed. It also includes the following steps:

[0024] (a): The two sides of the wire rubber plug 61 are formed with wire grooves 45, the wire grooves 45 are in the shape of a "V", and each core wire is pressed into the corresponding wire grooves 45 of the wire rubber plug 61. The tail end of the rubber plug 61 is inserted into the wire;

[0025] (b): The two sides of the puncture-type rubber plug 41 are also formed with wire grooves 45, the wire grooves 45 are in the shape of "V", and there are undercut locking positions formed in the wire grooves 45, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com