Automatic gas-liquid separation condenser for central air conditioning unit

A central air-conditioning and gas-liquid separation technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of high production and operation costs, insufficient utilization of heat exchange area, large volume and weight of heat exchangers, etc. problems, to achieve the effect of increasing operating costs, saving exhaust valves, and improving the decline in heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

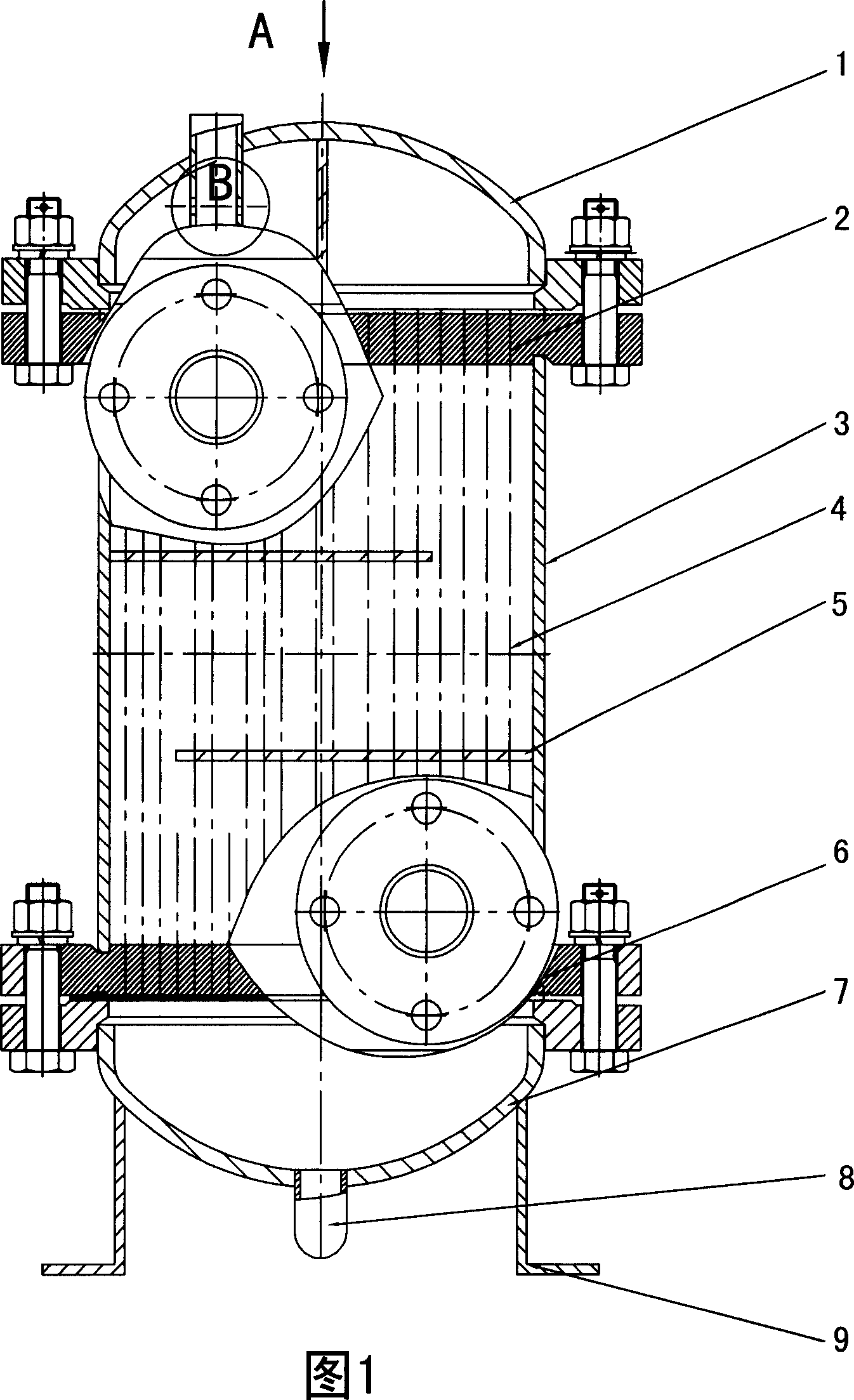

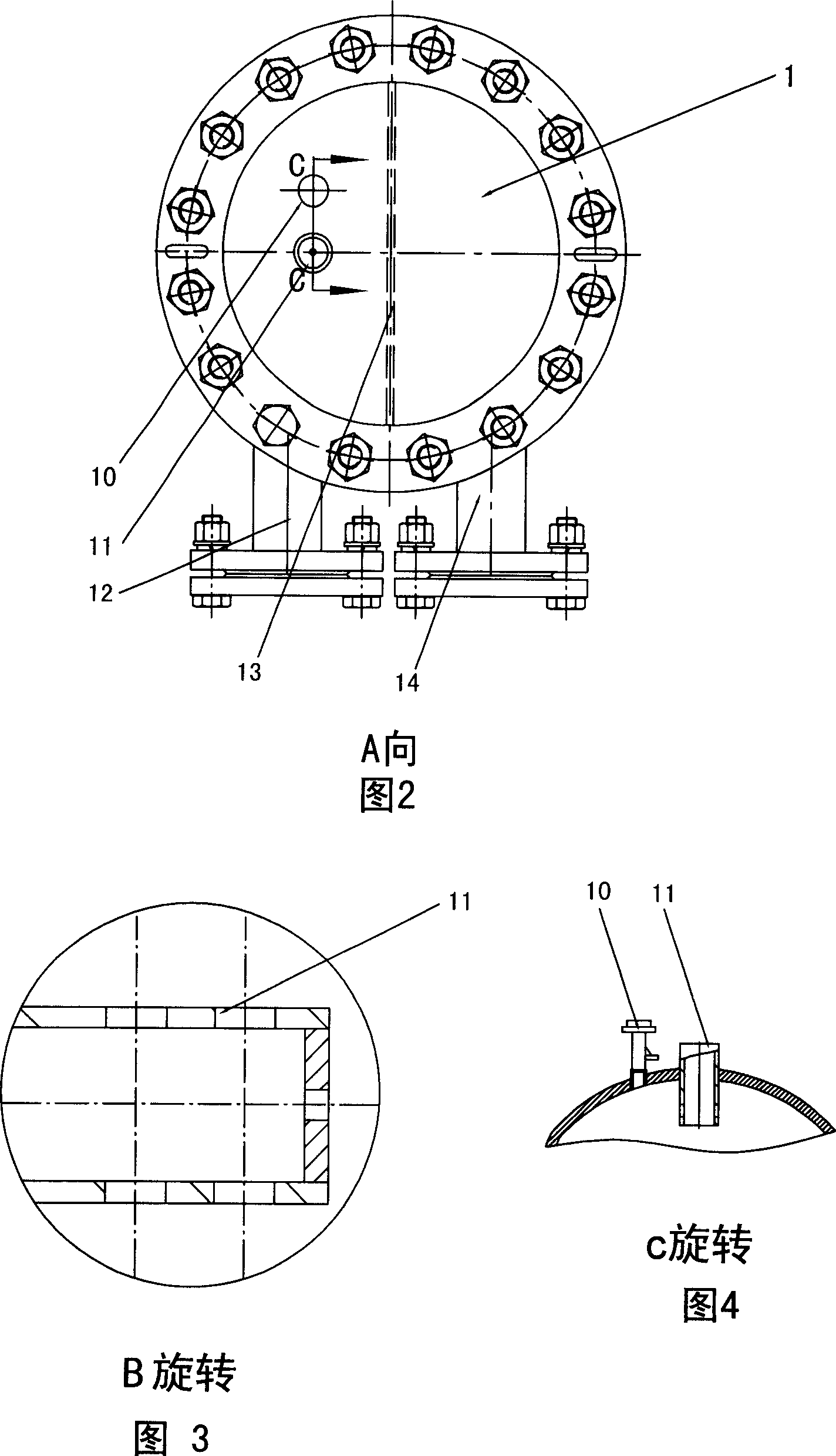

[0019] Below in conjunction with accompanying drawing 1-4, central air-conditioning unit of the present invention is further described with automatic gas-liquid separation condenser:

[0020] Referring to Figure 1-2: The automatic gas-liquid separation condenser for the central air-conditioning unit consists of a head 1, an upper tube plate 2, a heat exchanger body 3, a heat exchange tube group 4, a baffle plate 5, a lower tube plate 6, a lower The head 7, the liquid outlet pipe 8, the base 9, the safety valve 10, the air inlet pipe 11, the cooling water outlet pipe 12, the steam partition 13, and the cooling water inlet pipe 14 are composed. The heat exchanger body 3 is a first stage, and the heat exchange tube group 4 is arranged inside, the heat exchange tube group 4 is passed through steam, and the heat exchanger body 3 is passed through with cooling water. The heat exchange tube group 4 is provided with a baffle group 5, and the baffle group 5 is one or two or more, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Load | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com