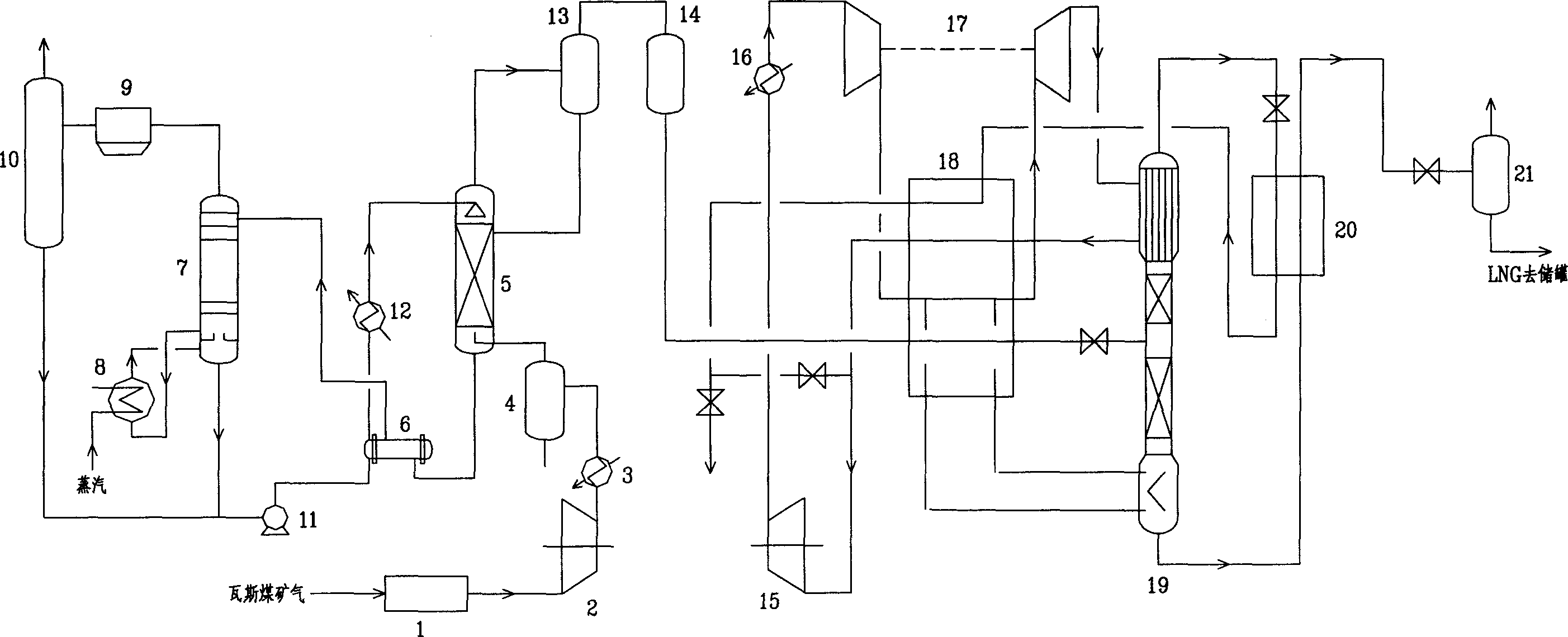

Process technology for preparing liquefied natural gas with coal-mine gas as crude material

A technology for coal mine gas and liquefied natural gas, which is applied in gas fuel, fuel, petroleum industry and other directions, can solve the problem of lack of practice in cascade circulation, and achieve the effects of easy control and maintenance, good performance, and convenient storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Production of liquefied natural gas (LNG) from coal mine gas

[0038] 1. Raw material gas under normal temperature and pressure: 310m 3 / h

[0039] 2. Deoxidize the raw material gas (in the deoxygenation device, the oxygen in the gas gas will be burned to generate CO when it meets red hot coke 2 , a small amount of CO 2 It is reduced by charcoal to further generate CO), after dust removal and crude H removal 2 O and other pretreatments to obtain gas that can be safely used in the production of LNG. Sampling and analysis components are as follows: CH 4 _47.52%, N 2 _44.12%, O 2 _0.45%, CO 2 _4.88%, CO_2.11%, H 2 _1.15%, H 2 150mg / m for S and others 3

[0040] 3. Use a 1-5 / 50 compressor to pressurize the above gas to 2.5-3.5MPa and enter the ethanolamine absorption tower to remove CO 2 and H 2 S impurity, so that its content is reduced to ≤10PPm, and then enters the molecular sieve dryer to reduce the water in the gas to ≤10PPm. The purified gas enters the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com