Treatment processes of coke oven gas desulfurization and decyanation waste water

A technology for desulfurization, decyanation, and treatment methods, which is applied in the field of industrial wastewater separation and recovery, can solve the problems that small and medium-sized enterprises cannot use, cannot be handled properly, and has high equipment requirements, achieves significant economic and social benefits, feasible technical routes, and processes. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

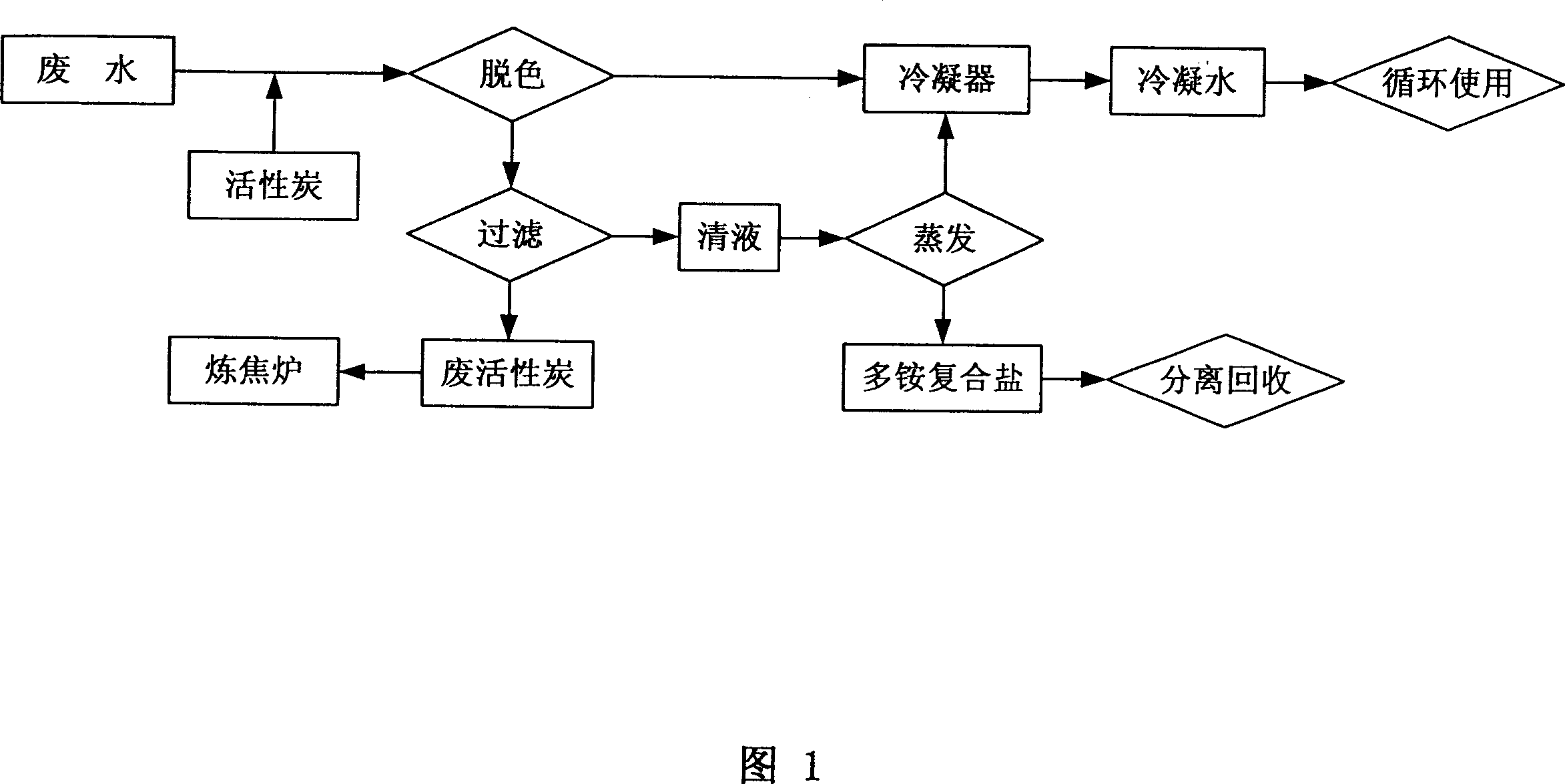

[0013] The present invention starts from the analysis of the existing technical situation and its existing deficiencies, and finds a relatively ideal treatment method by exploring and testing, and divides the waste water formed after coke oven gas desulfurization and decyanation treatment by HPF method into two parts, one of which is Water, the other part is polyammonium salt solids with ammonium thiocyanate, ammonium thiosulfate, ammonium sulfate and other substances as the main components. Polyammonium salt solids try to maintain their original composition ratio, and the corresponding compounds can be obtained after separation and purification.

[0014] As shown in Figure 1, the main process of this method is to add activated carbon to the wastewater for decolorization treatment, and then filter to obtain clear liquid and waste activated carbon. The waste activated carbon is returned to the coal yard and enters the coke oven, and the clear liquid is evaporated and concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com