Aluminium-made extrusion slender section

An extrusion molding and profile technology, which is used in tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of extremely high quality stability requirements, difficult cost control, and complex flat tube structure, and achieves high resistance to The effect of corrosion resistance, compact structure, high radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

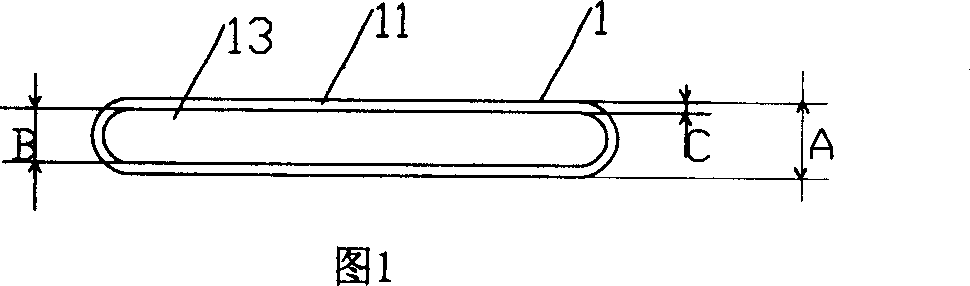

[0087] Referring to FIG. 1 , an aluminum extruded thin-walled profile 1 is composed of a flat channel tube 11 with equal thickness on the outer periphery of the tube body. The channel tube 11 has a flow channel 13 for cold and hot preparations. The wall thickness C of the pipe body wall is less than 0.45mm, and can even be less than 0.15mm. The cross-sectional shape of the hot and cold preparation channel 13 is approximately elliptical.

Embodiment 2

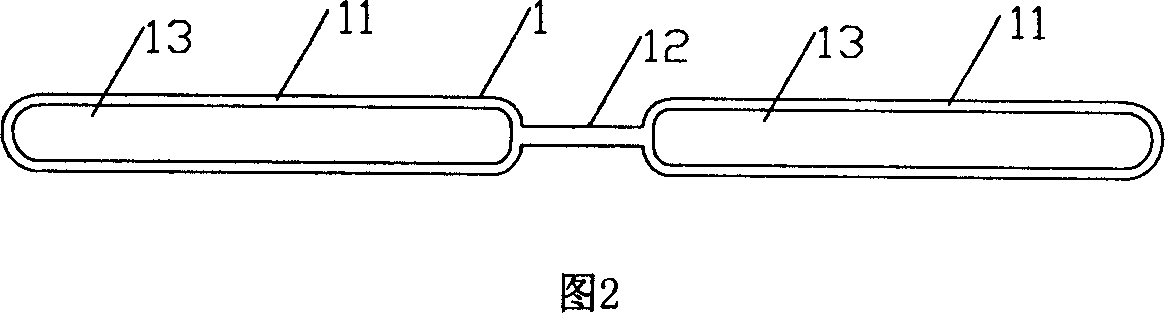

[0089] Referring to Fig. 2, an aluminum extruded thin-walled profile 1 is composed of two channel tubes 11 with equal thickness and flat shape on the outer periphery of the tube body wall. The two channel tubes 11 are parallel and independent to each other, and the channel tubes 11 pass through The connecting portion 12 is connected transversely to form a dual-channel parallel flow pipe. The connection part 12 is generally a flat strip structure, and its thickness is about twice the thickness of the tube wall of the channel tube 11 . If the thickness is less than 0.9mm, it can even reach 0.3mm. The length of the connecting part 12 is shorter than that of the fluid pipe 11, so as to facilitate the installation and positioning of the high-performance cooling and heat exchange products on the header. There is a symmetrical structure between the two channel pipes 1 .

[0090] There is a hot and cold preparation channel 13 inside the channel tube 11 . The two-channel pipe 11 is ...

Embodiment 3

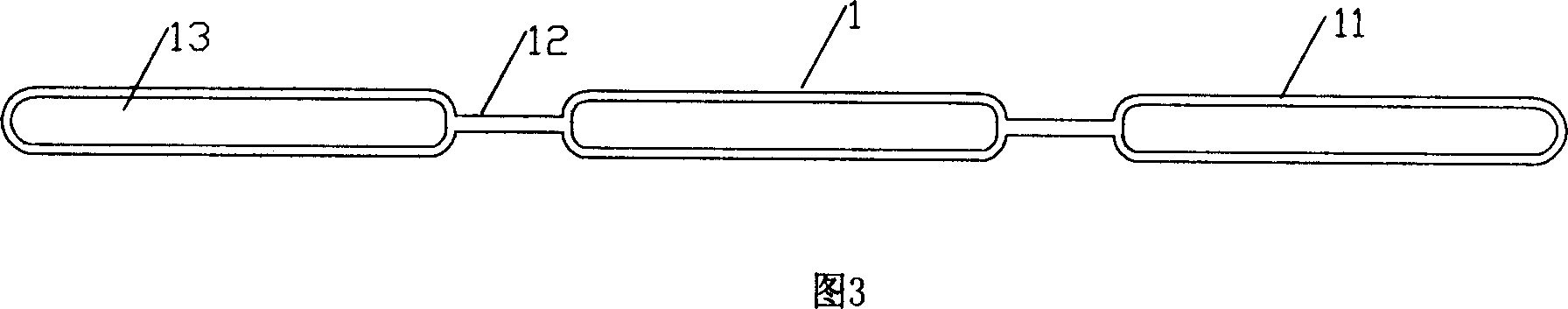

[0092] Referring to FIG. 3 , an aluminum extruded thin-walled profile 1 is composed of three or more channel tubes 11 of equal thickness and flat shape on the outer periphery of the tube body wall. The three channel tubes 11 are parallel to each other and independent, and the channel tubes 11 They are horizontally connected by connecting parts 12 to form a parallel flow tube with three or more channels. The connection part 12 is generally a flat strip structure, and its thickness is about twice the thickness of the tube wall of the channel tube 11 . If the thickness is less than 0.9mm, it can even reach 0.3mm. The length of the connecting part 12 is shorter than that of the fluid pipe 11, so as to facilitate the installation and positioning of the high-performance cooling and heat exchange products on the header. The three channel pipes 11 are symmetrical structures.

[0093] The channel pipes 11 may be of a symmetrical structure or an asymmetrical structure. For example, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com