Evaporation type condenser

A technology for evaporative condensers and condenser coils, applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of reducing equipment service life, wasting energy, reducing heat transfer coefficient, etc., and achieve the goal of reducing maintenance Trouble, prolonging service life, and improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

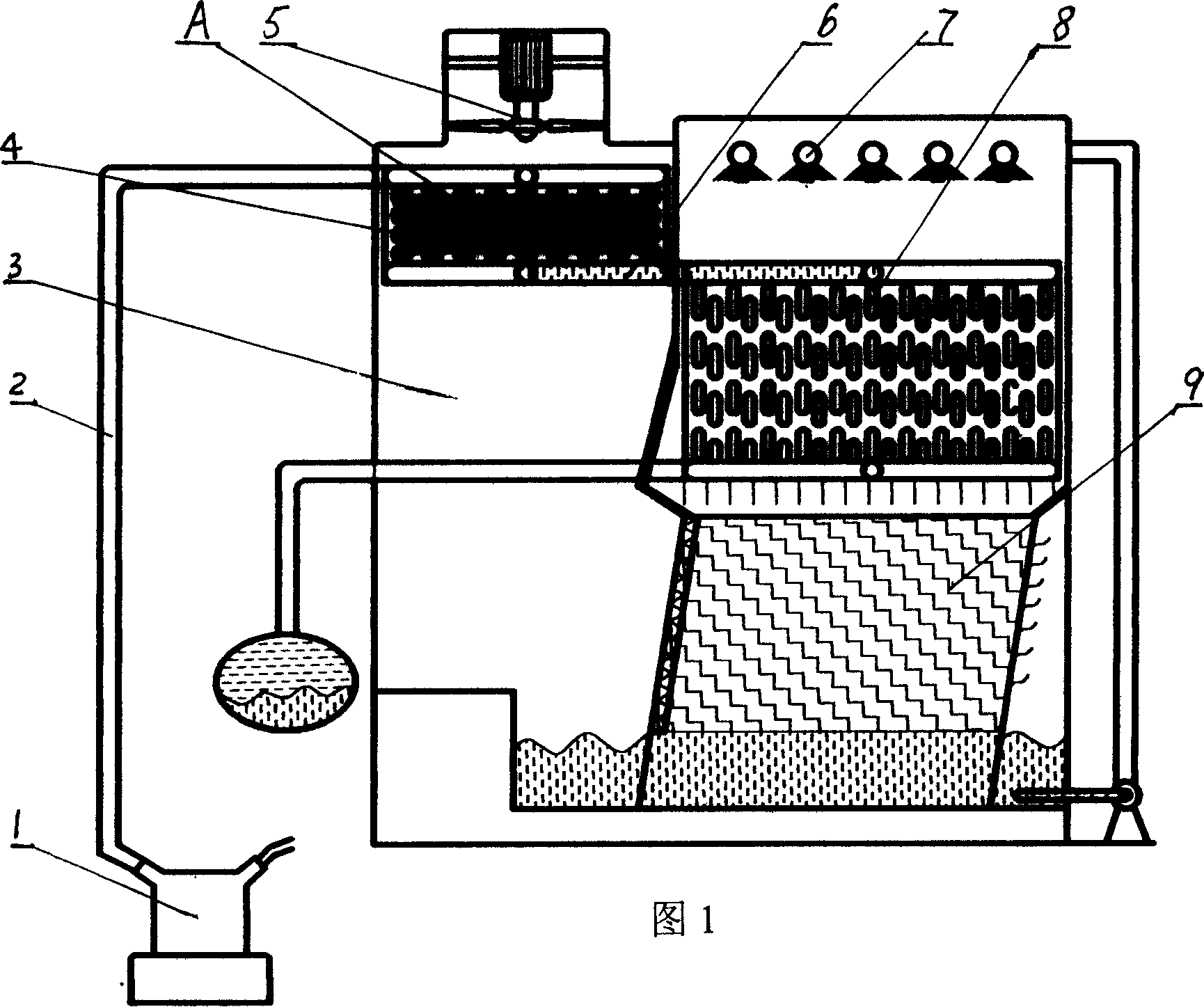

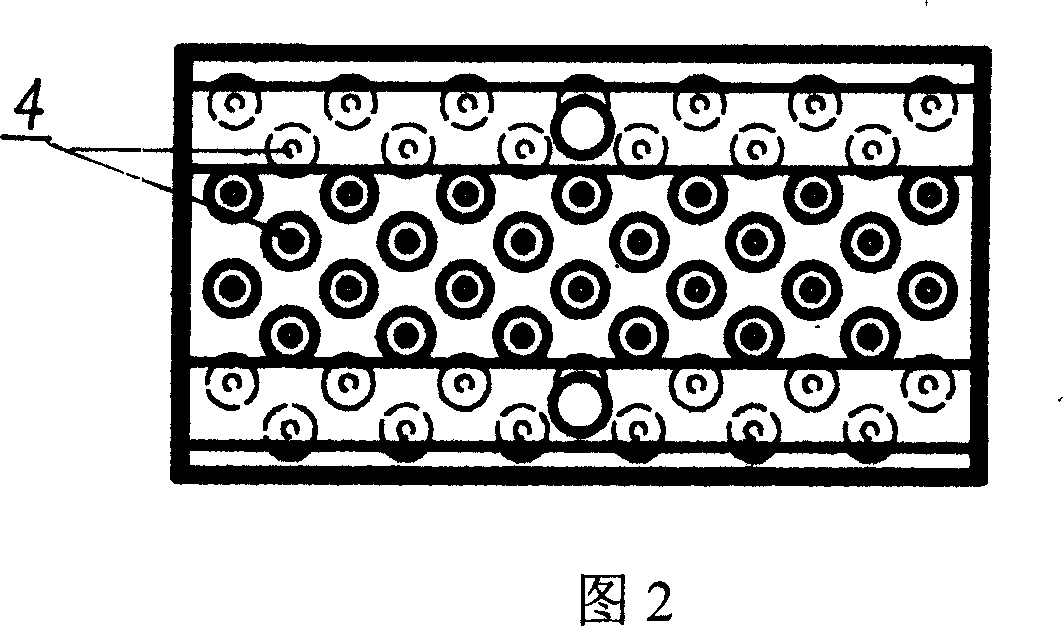

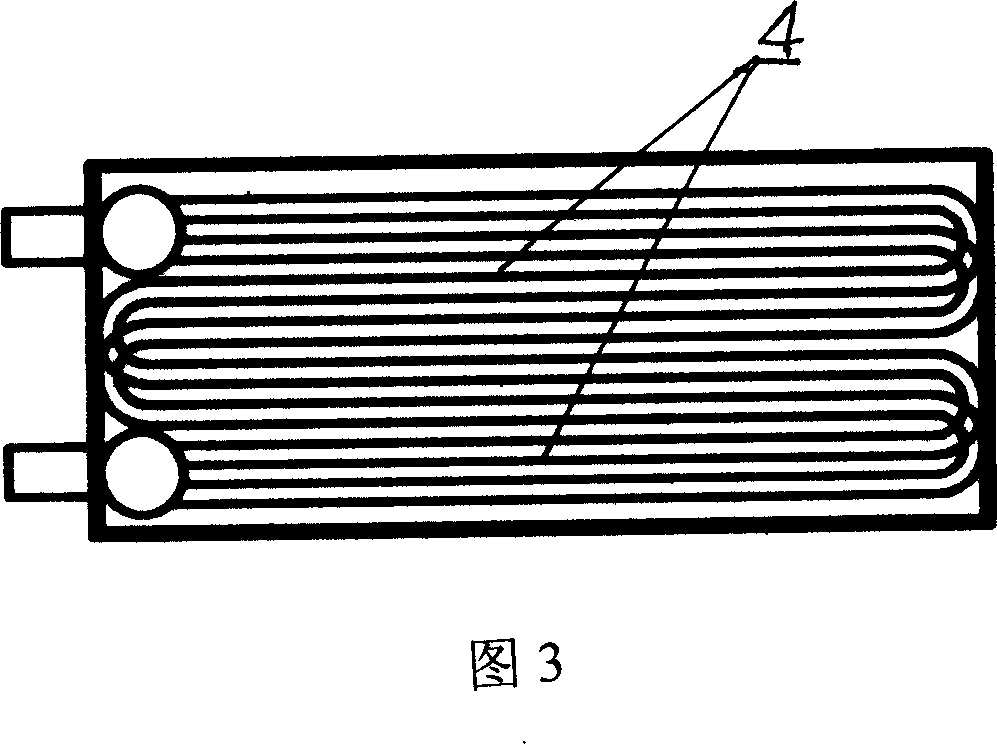

[0012] Embodiment 1: This evaporative condenser includes a compressor 1 and an evaporative condenser, and a precooling coil 4 is installed in the negative pressure chamber 3 of the evaporative condenser, and the precooling coil 4 is located at the side of the axial flow fan 5 below. The inlet end of the pre-cooling coil is connected to the compressor 1 through the conduit 2, and the outlet end is connected to the condenser coil 8 through the conduit 6. The condenser coil 8 is located under the spray water pipe 7, and the condenser coil 8 Below is the heat exchange layer 9 of the evaporative condenser made of PVC material.

[0013] The tube shape of the pre-cooling coil can be circular, elliptical or any other shape; in order to make the heat dissipation better, the outer wall of the pre-cooling coil 4 should have fins 10 .

[0014] The total length of the condenser coil 8 in the evaporative condenser described in the present invention can be identical with existing; In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com