Gas field methanol sewage disposal process

A technology of sewage treatment and process, which is applied in the field of methanol sewage treatment process in gas fields, and can solve problems such as scaling of heat exchange equipment, plugging of rectification tower packing, corrosion of equipment and pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

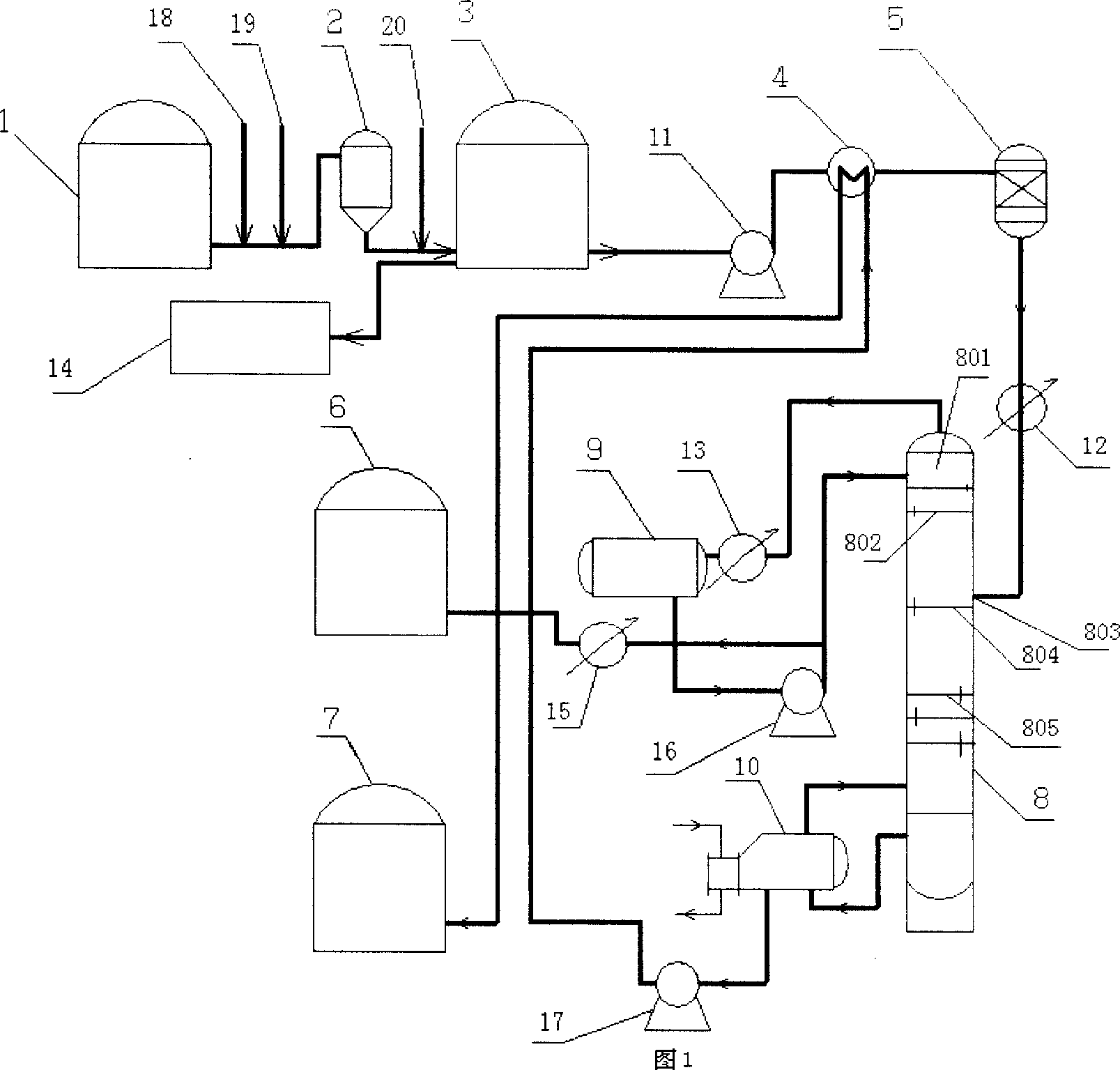

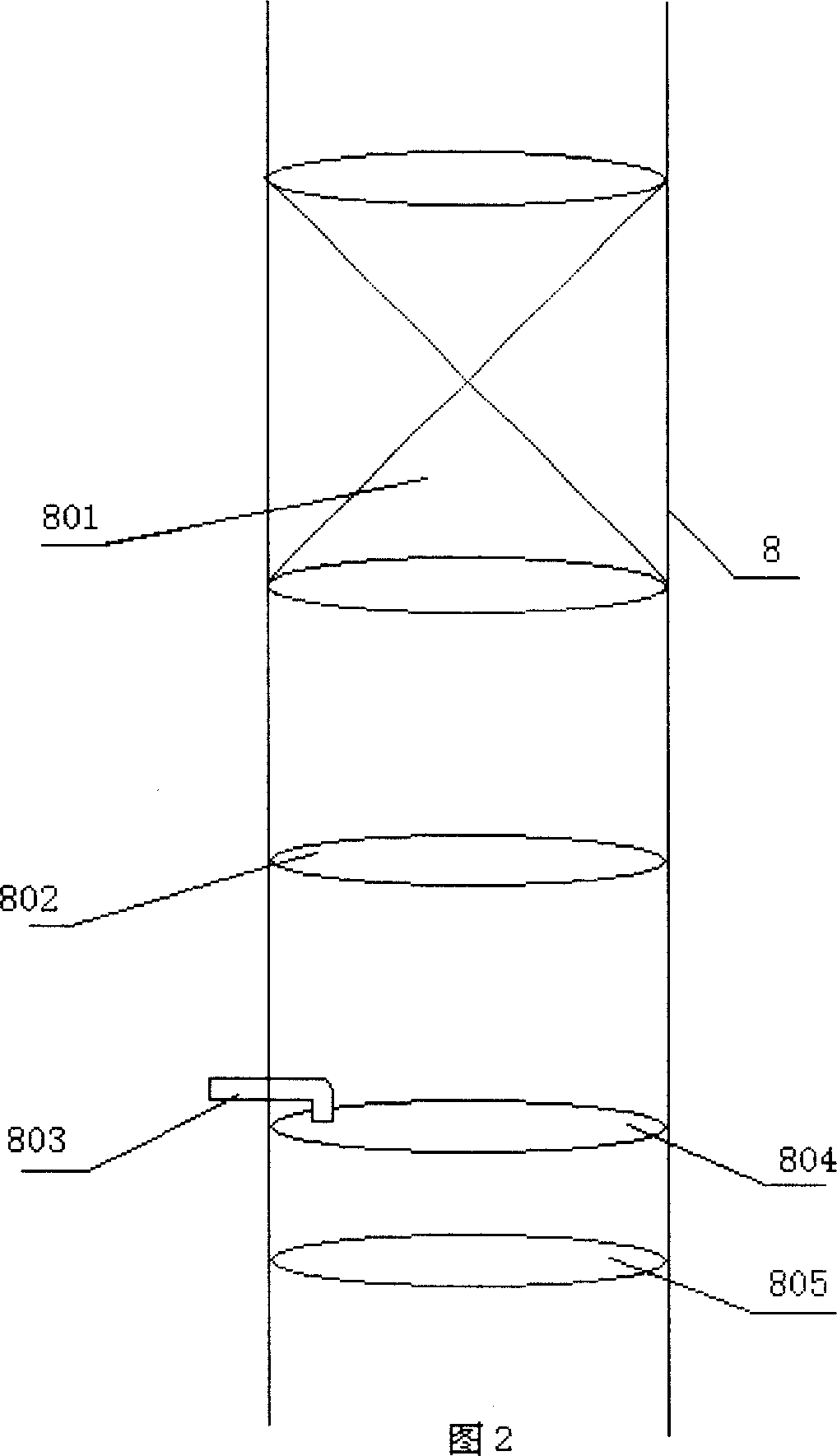

[0025] As shown in Figure 1, the gas field sewage entering the oil removal tank 1 is placed in the coagulation settling tank 3 after the pretreatment process. Heating heat exchanger 4, preheating the outlet water from the bottom of rectification tower 8 to 40-65°C, entering raw material heating heat exchanger 12, heating with steam to boiling point 90°C, and entering rectification tower 8 through inlet 803 in the middle of rectification tower ; The liquid phase in the rectification tower 8 flows from top to bottom and contacts with the secondary steam moving from bottom to top in countercurrent to complete the heat and mass transfer process; Potential difference enters the kettle-type reboiler 10, partly vaporizes and returns to the bottom of the rectifying tower 8 after being heated by steam, and part of it is pumped out as the bottom product of the rectifying tower 8 with a pump 17, and enters the water storage after exchanging heat with the feed liquid to about 40°C tank 7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com