Optical disc and optical disc device

An optical disc and optical head technology, applied in the directions of beam source, optical recording head, optical recording carrier, etc., can solve the problem of not being able to obtain the optimal value of the recording power of the L0 layer, and achieve the effect of reducing the recording capacity and reducing the shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

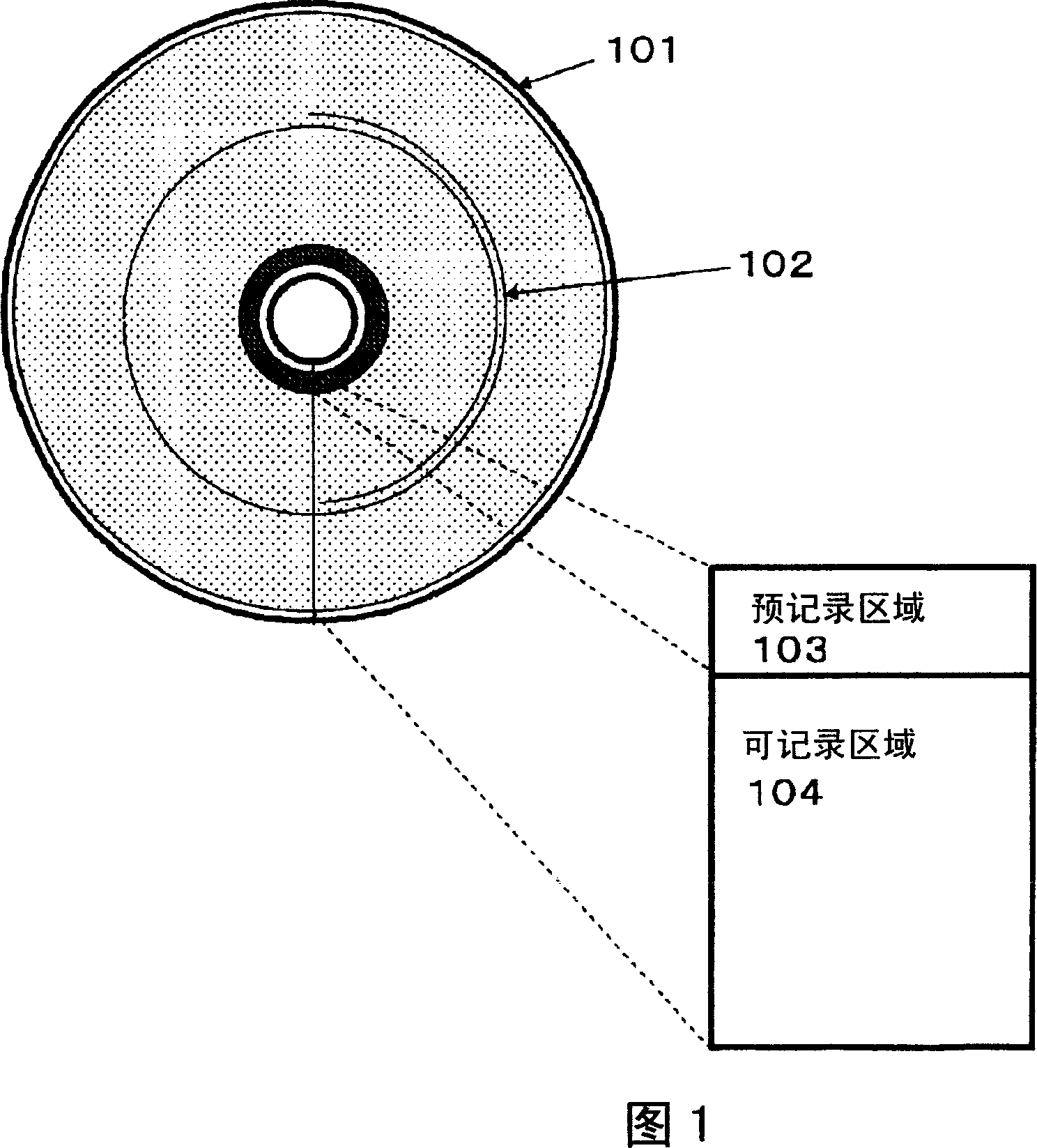

[0040] FIG. 1 shows the structure of an optical disc 101 according to Embodiment 1 of the present invention, particularly the structure of a first information recording layer.

[0041] On the optical disc 101, a plurality of tracks (tracks) 102 are formed concentrically. Alternatively, a single track 102 may be formed spirally on the optical disk 101, or a plurality of tracks 102 may be formed spirally.

[0042] The area of the optical disc 101 includes a pre-recorded area 103 and a recordable area 104 .

[0043] Various parameters necessary for accessing the optical disc 101 are stored in the pre-recorded area 103 .

[0044] In the recordable area 104, recording learning and recording and reproduction of user data are performed.

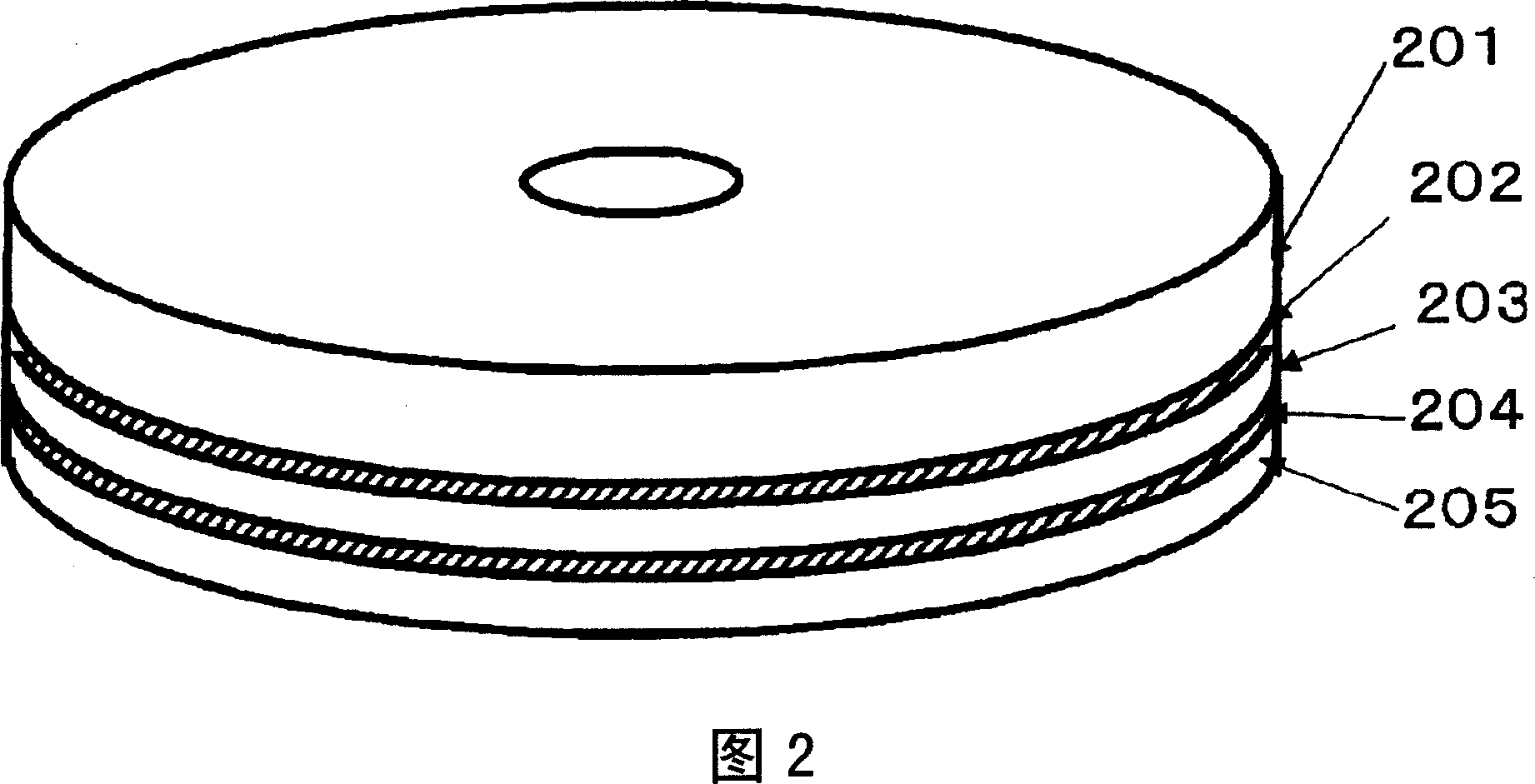

[0045] Fig. 2 shows the structure of a single-sided two-layer type optical disc of the present invention.

[0046] In FIG. 2, 201 is a substrate, 202 is a first information recording layer, 203 is a space layer such as an adhesive resin, 204 is...

Embodiment approach 2

[0071] FIG. 8 is a layout diagram showing the radial positional relationship of main parts of the optical disk area in another embodiment of the present invention.

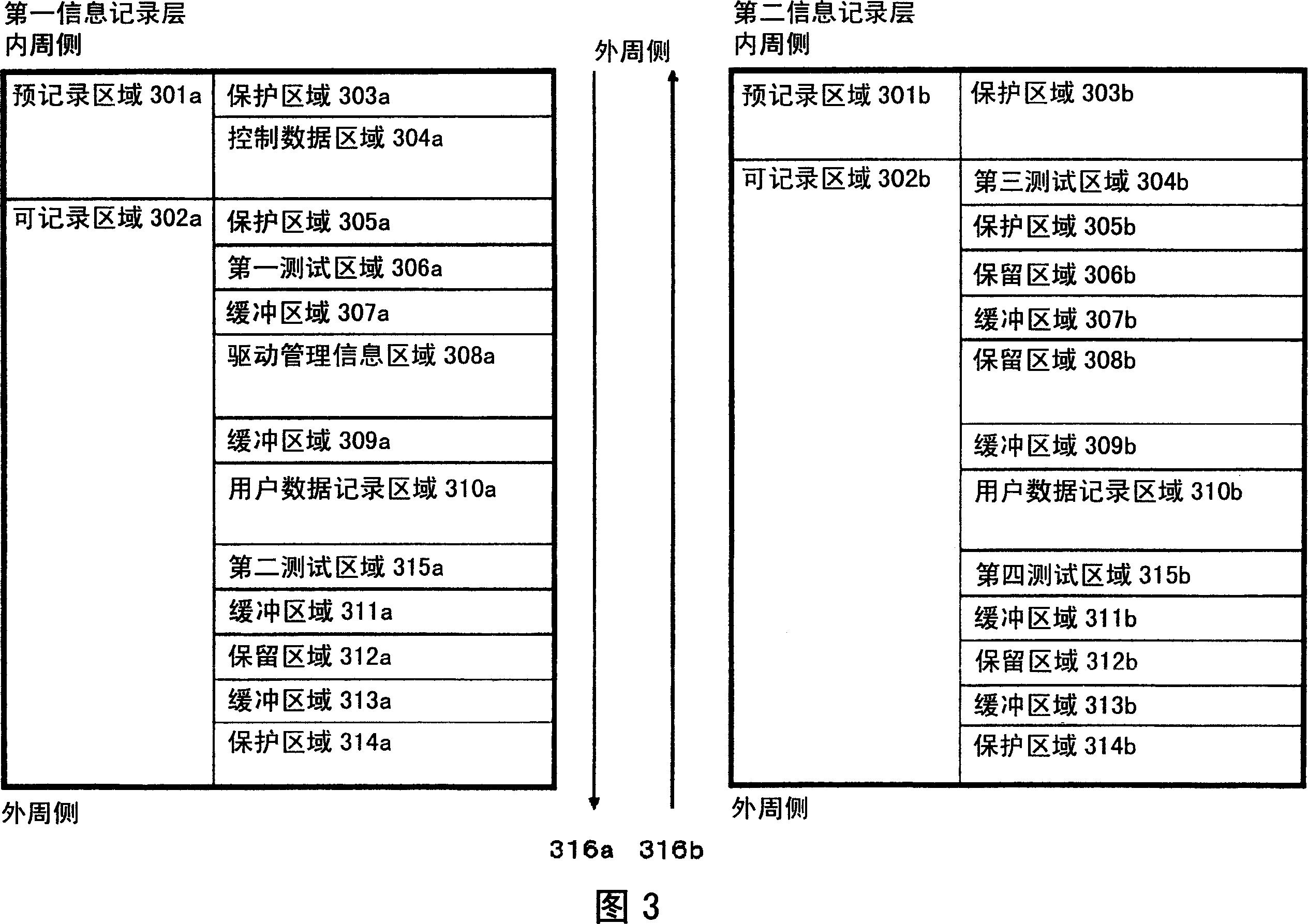

[0072] In this figure, the upper part represents the protection area 503a, the control data area 504a, the protection area 505a, the first test area 506a, the buffer area 507a, the drive management information area 508a, the buffer area 509a, the user data recording area of the first information recording layer. area 510a and a second test area 515a. In this figure, the lower part represents the protected area 503b, the third test area 504b, the reserved area 505b, the protected area 506b, the reserved area 507b, the buffer area 508b, the reserved area 509b, the buffer area 510b, the user data recording layer of the second information recording layer. area 511b and a fourth test area 515b. The rest of the structure and the contents of each area are substantially the same as those of the two-layer optical disc a...

Embodiment approach 3

[0086] An optical disc device for recording on the optical disc described in Embodiment 1 or 2 will be described with reference to FIGS. 9 and 10 .

[0087] FIG. 9 is a block diagram showing the outline of an optical disc device 600 .

[0088] In FIG. 9, 601 is an optical disc. The optical disc 601 has the structure described in the first or second embodiment. Among them, the optical disc device 600 can record on an optical disc having a conventional structure, for example, a single-layer optical disc.

[0089] In addition, 602 is a semiconductor laser, 603 is a collimating lens, 604 is a beam splitter, 605 is a converging mechanism, 606 is a converging lens, 607 is a light detection mechanism, 608 is a reproduction signal calculation mechanism, and 609 is a focus control mechanism. , 610 is a tracking control mechanism, 611 is an actuator, 612 is a controller, 613 is a laser drive mechanism, 615 is a signal processing unit.

[0090] Here, an optical head is constituted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com