Holder for high-temperature high-pressure glass microscopic model

A microscopic model, high temperature and high pressure technology, applied in the direction of mining fluid, measurement, wellbore/well components, etc., can solve the problems that the experimental research of the transparent pore model of microscopic simulation cannot be completed, and the reference value is not high, so as to improve the degree of experimental simulation and application The effect of high range, high reference value, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

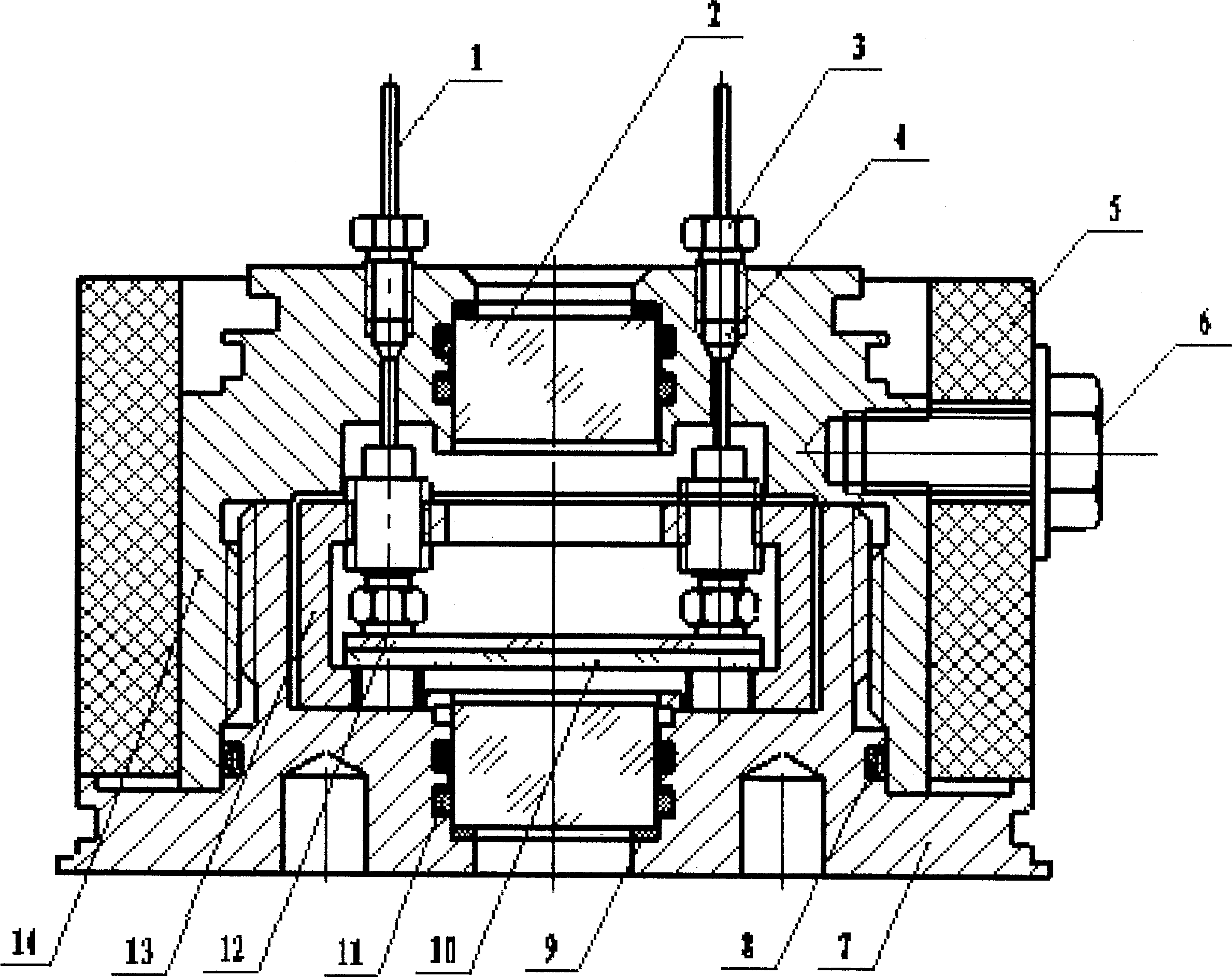

[0017] Embodiment 1: refer to accompanying drawing 1. The high-temperature and high-pressure glass microscopic model holder is mainly made of a model bed base 7, made of stainless steel, with an external diameter of 120 millimeters and a height of 45 millimeters, with external threads on the upper end. Model bed body loam cake 14, stainless steel material is made, and external diameter 90 millimeters, height 55 millimeters, internal thread is arranged at the lower end. Model bed body base 7 is threadedly connected with model bed body loam cake 14. An O-shaped sealing ring 8 is arranged between the model bed body base 7 and the model bed body upper cover 14 . Model bed body base 7 and model bed body loam cake 14 centers have the through hole with step, respectively have a glass window 2 in the through hole. The glass window 2 is made of transparent glass with a thickness of 15 mm and a diameter of 24 mm. Gasket 9 is arranged on the center through hole step of model bed body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com