Process for preparing hydrogenated C5/C9 copolymerized petroleum resin

A technique of copolymerizing petroleum resin and hydrogen-to-oil ratio, which is applied in the field of hydrogenated petroleum resin preparation to achieve the effect of expanding the application range, low bromine value, and mild hydrogenation reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

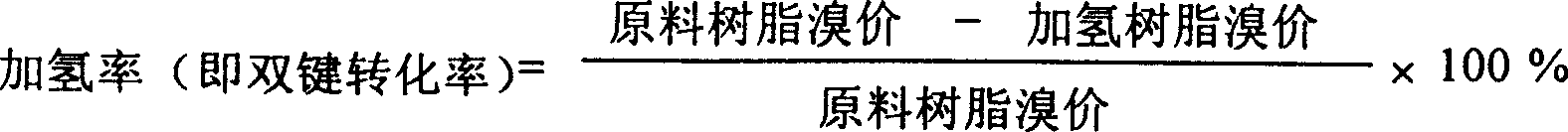

Method used

Image

Examples

Embodiment 1

[0048] In this example, the hydrogenation reaction device is a small-scale gas-liquid-solid medium-pressure hydrogenation reaction device with a catalyst loading capacity of 40ml, and a 1Cr18Ni9Ti fixed-bed reactor, a three-stage temperature-controlled reaction furnace, and an integrated preheating mixer are selected. The design pressure is 10Mpa, and the actual temperature control accuracy of the device is less than 1°C. The gas feed is measured by a gas mass flow controller, the tail gas is measured by a wet flow meter, and the gas raw material flow control range: 0 ~ 500ml / min (MAX). The liquid reaction material is measured by a double plunger metering pump, and the liquid flow control range: 0.1 ~ 100ml / h (MAX). Pressure detection uses a pressure sensor connected to a digital display meter, and an intelligent control digital display meter is used for temperature control and detection.

[0049] The hydrogenation catalyst adopts JH-1 type nickel-supported Al 2 o 3 Support...

Embodiment 2~8

[0053] Examples 2-8 realize the present invention at different hydrogenation reaction temperatures, and optimize the reaction temperature.

[0054] Concrete implementation process is the same as embodiment 1, selects the JH-1 catalyst among the embodiment 1 for use, catalyst volume 40ml, raw material concentration 20%, hydrogenation reaction pressure 3.0MPa, space velocity 0.5h -1 , Hydrogen oil ratio 600:1. The hydrogenated petroleum resin obtained is shown in Table 4 by changing the hydrogenation reaction temperature within the range of 190-280°C.

[0055] Table 4 Effect of reaction temperature

[0056]

[0057] Raising the reaction temperature can speed up the reaction speed, promote the hydrogenation reaction, and reduce the impurity content, but if the temperature is too high, it will cause degradation side reactions, and accelerate the carbon deposition on the catalyst, reducing the service life of the catalyst. As the reaction temperature increases, the colo...

Embodiment 9~13

[0059] Examples 9-13 realize the present invention under different hydrogenation reaction pressures, and optimize the reaction pressures.

[0060] The specific implementation process is the same as in Example 1, select the JH-1 catalyst in Example 1, the catalyst volume is 40ml, the raw material concentration is 20%, the hydrogenation reaction temperature is 250 ° C, and the space velocity is 0.5h -1 , Hydrogen oil ratio 600:1. The hydrogenated petroleum resin obtained is shown in Table 5 by changing the hydrogenation reaction pressure within the range of 1.0-6.0 MPa.

[0061] Table 5 Effect of reaction pressure

[0062] Example

[0063] As can be seen from Table 5, increasing the pressure can increase the reaction speed, which is conducive to the diffusion of raw materials to the catalyst, but increasing the pressure will increase the consumption of equipment investment and energy consumption. Considering the hydrogenation depth in terms of energy saving, reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com